Laser stimulated emission loss three-dimensional super-resolution differential confocal imaging method and device

A laser stimulated emission and differential confocal technology, which is applied in the direction of optical devices, measuring devices, instruments, etc., can solve the problems of limited application, and achieve the effect of improving lateral resolution, improving linearity, and good linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

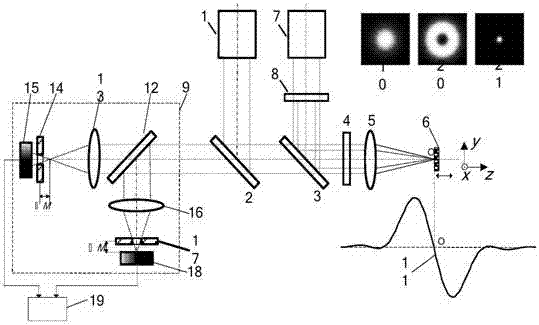

[0039] Such as figure 1 As shown, the laser stimulated emission loss three-dimensional super-resolution differential confocal imaging method, the test steps are as follows:

[0040] First, the wavelength emitted from the excitation laser system 1 is λ 1 After being reflected by the first dichroic mirror 2, the parallel light beam passes through the second dichroic mirror 3 and the quarter-wave plate 4 and is focused on the surface of the tested sample 6 by the objective lens 5. The light (or excited fluorescence) passes through the objective lens 5, the quarter-wave plate 4, the second dichroic mirror 3 and the first dichroic mirror 2 again, and enters the differential confocal detection system 9; A pinhole 14 and a first detector 15 are placed at the front-focus position of the first condenser lens 13 at +M, a second pinhole 17 and a second detector 18 are placed at the post-focus position of the first condenser lens 16 at -M, and the distance M corresponds to The optically...

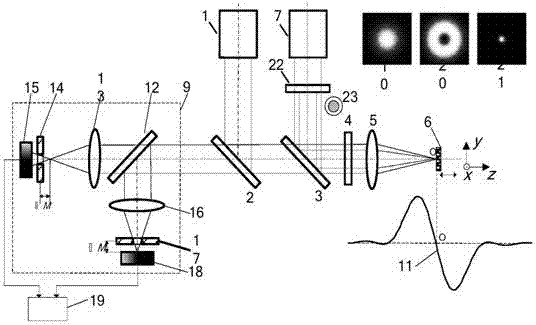

Embodiment 2

[0046] Such as figure 2 As shown, the annular beam shaping system 22 may be an annular pupil filter, a binary optical diffraction device with an annular phase distribution, etc., and shapes the quenched laser beam into an annular beam 23 . All the other measuring methods are the same as in Example 1.

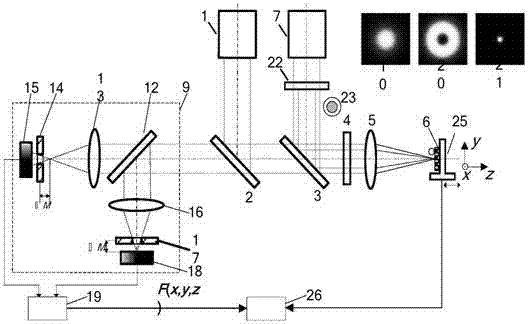

Embodiment 3

[0048] Such as image 3 As shown, a schematic diagram of an embodiment of a laser stimulated emission loss three-dimensional super-resolution differential confocal imaging device, the principle of which is:

[0049] First, the sample 6 to be tested is placed on the scanning table 25. The scanning table 25 adopts a macro-micro combination method, and a micro-displacement two-dimensional table based on a piezoelectric ceramic driver PZT and a capacitive sensor is integrated on the x-y macro table. , start the measurement software in the main control computer 26.

[0050] The parallel light beam emitted by the excitation laser system 1 is reflected by the first dichroic mirror 2, passes through the second dichroic mirror 3 and the quarter-wave plate 4, and then is focused on the surface of the sample 6 by the objective lens 5, and the band reflected by the sample 6 is The light (or excited fluorescence) with sample information passes through the objective lens 5, the quarter-wav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com