A preparation method of polymer-coated sulfur composite material for positive electrode of lithium-sulfur battery

A technology of composite materials and polymers, applied in the field of electrochemistry, can solve the problems of low sulfur loading, sulfur dissolution, etc., and achieve the effects of simple preparation process, high initial discharge capacity, and improved cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Dissolve butadiene rubber and elemental sulfur in toluene, the mass ratio of butadiene rubber and elemental sulfur is 1:4, add ultraviolet light initiator dialkoxy acetophenone, the amount of ultraviolet light initiator is the mass of butadiene rubber After stirring evenly, under the protection of nitrogen, irradiate with 365 nm ultraviolet light for 12 hours, then separate the reaction product, wash, and dry to obtain the polymer-coated sulfur composite material. Its structure diagram is as follows figure 1 shown.

[0034] After infrared testing, it was found that the absorption peak of the C=C double bond in the infrared spectrum completely disappeared, indicating that the butadiene rubber had fully participated in the reaction; in addition, through the thermogravimetric test, the sulfur content in the composite material was 78.2 wt%.

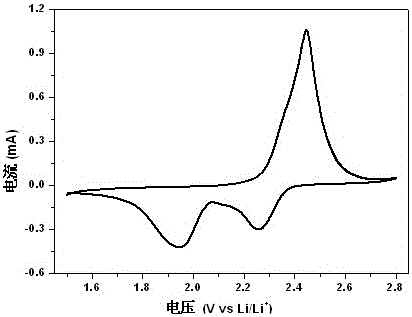

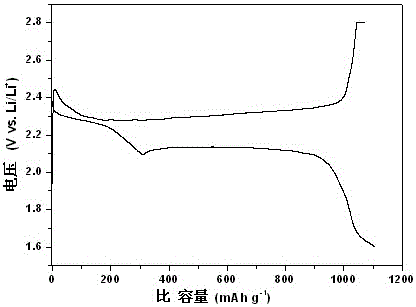

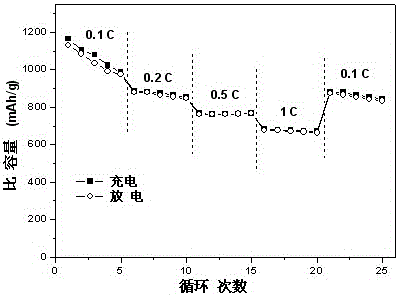

[0035] Electrochemical performance test:

[0036] The polymer-coated sulfur composite material prepared above is used as the positiv...

Embodiment 2

[0043] Dissolve polyisobutene and elemental sulfur in toluene, the mass ratio of polyisobutylene and elemental sulfur is 1:9, add ultraviolet light initiator α-hydroxyalkyl phenone, the amount of ultraviolet light initiator is 1 wt of the mass of polyisobutylene %, after stirring evenly, under the protection of nitrogen, irradiate with 254 nm ultraviolet light for 2 hours, then separate the reaction product, wash and dry to obtain the polymer-coated sulfur composite material.

[0044] Infrared test results found that there is still an absorption peak of C=C in the infrared spectrum, indicating that the C=C reaction is not complete under the irradiation of ultraviolet light of this wavelength for 2 hours. In addition, by thermogravimetric test, the sulfur content in the composite material is 87.7 wt%.

[0045] Electrochemical performance test:

[0046] The composite material obtained in Example 2 was assembled into a button battery, and its preparation method was the same as t...

Embodiment 3

[0048] Dissolve butadiene rubber and elemental sulfur in toluene, the mass ratio of butadiene rubber and elemental sulfur is 1:9, add ultraviolet light initiator dialkoxy acetophenone, the amount of ultraviolet light initiator is the mass of butadiene rubber After stirring evenly, irradiate with 365 nm ultraviolet light for 2 hours under the protection of nitrogen, and then separate the reaction product, wash and dry to obtain the polymer-coated sulfur composite material.

[0049] After infrared testing, it was found that the absorption peak of the C=C double bond in the infrared spectrum completely disappeared, indicating that the butadiene rubber had fully participated in the reaction; in addition, the sulfur content in the composite material was 87.1 wt% through thermogravimetric testing.

[0050] Electrochemical performance test:

[0051] The composite material obtained in Example 3 is assembled into a button battery, and its preparation method is the same as that of Embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com