Air-cooling device for industrial production of purple sweet potato powder

A technology of purple potato powder and wind production, which is applied in the field of cooling equipment and air-cooled cooling, which can solve problems such as wasting time, affecting the efficiency of the work assembly line, and reducing daily output, so as to improve economic benefits, high-efficiency cooling treatment effect, and production The effect of speed increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

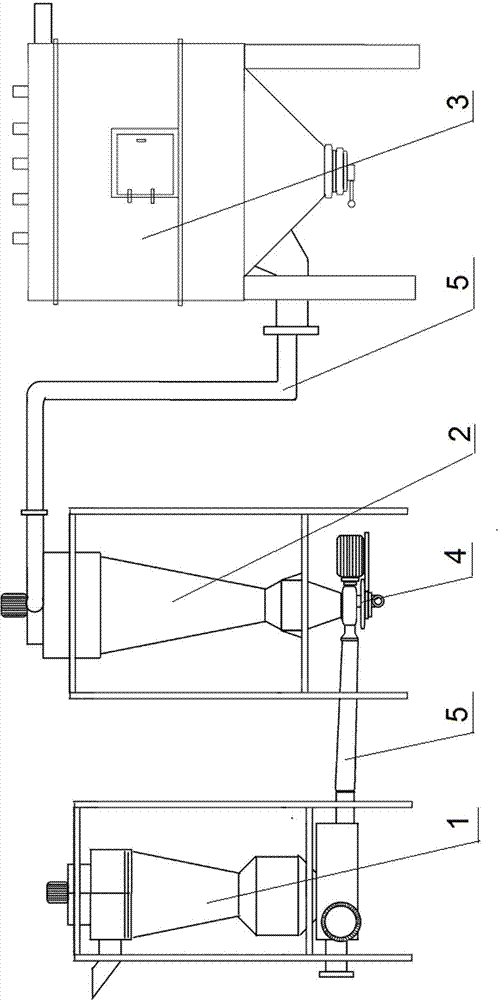

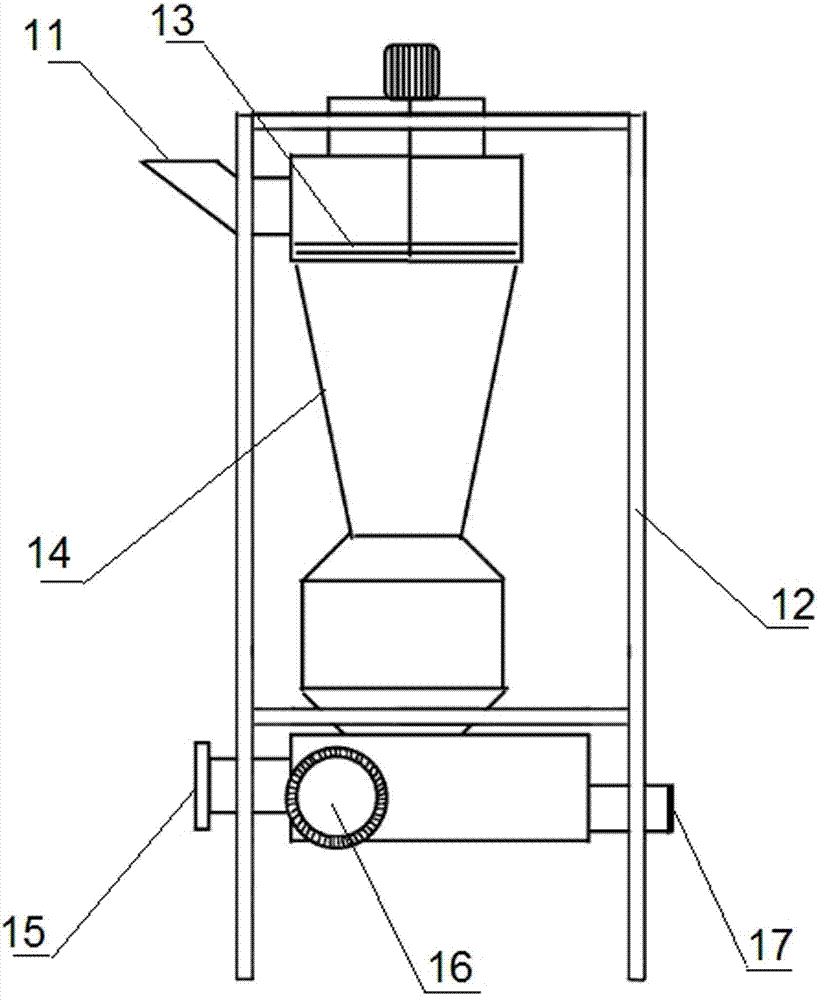

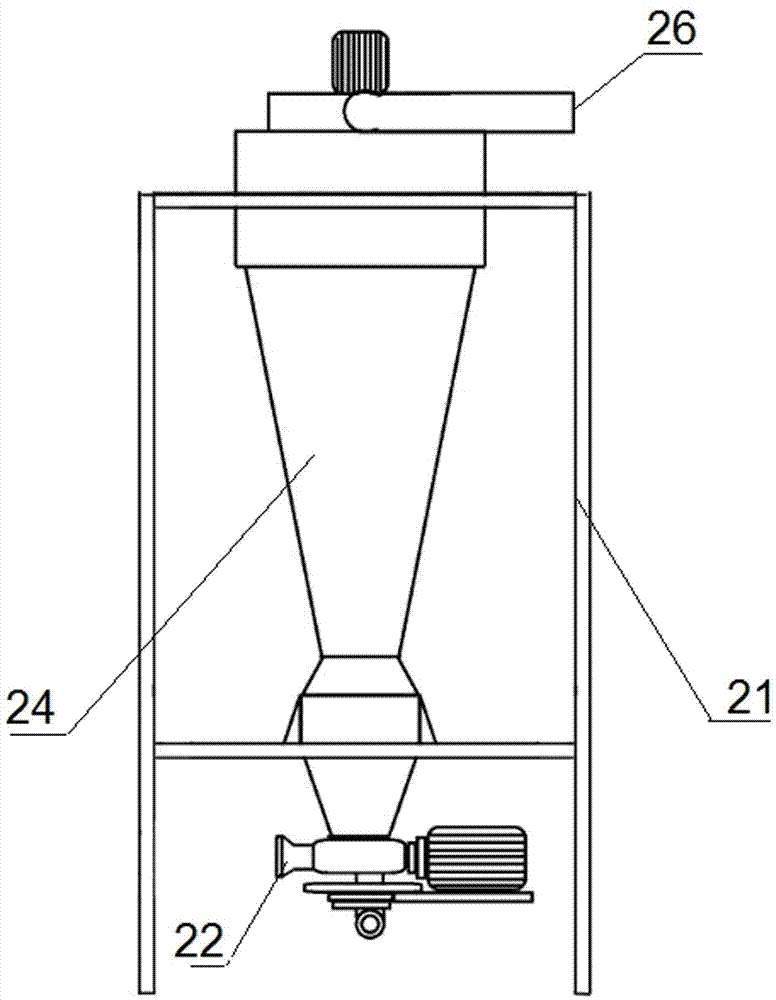

[0032] Example 1 ,Such as figure 1 As shown, the air-introduced conical box 1 is connected to the air-cooled conical box 2 through the delivery pipe 5, and the high-temperature purple potato powder is blown into the air-cooled conical box 2 by the air-introduced conical box 1 through the delivery pipe 5, and the high-temperature purple potato powder In the air-cooled conical box 2, it is blown from the bottom to the middle to complete the cooling. The dust collection box 3 is connected to the top of the air-cooled conical box 2 through the delivery pipe 5, and the powder recovery package is connected to the air-cooled conical box 2. At the bottom of the conical box 2, the fallen purple sweet potato powder enters the powder product recovery device 4 to complete the cooling, specifically, as figure 2 As shown, the high-temperature purple sweet potato powder enters the body 14 from the feed port 11, and under the suction force of the first induced draft fan 13, the powdery pur...

Embodiment 2

[0033] Example 2 : on the basis of embodiment 1, such as Figure 8 As shown, it also includes a water-cooling conveyor 6, and the water channel 67 is in the interlayer of the outer pipe body 61 and the inner pipe body 62. After the water pump 64 is turned on, cold water enters the water channel 67 from the water inlet pipe 65, and the end of the water channel 67 is connected to the water outlet pipe 66. , the cold water forms a cold flow circulation in the flow channel 67, and the flow channel 67 is meanderingly arranged in the interlayer of the outer tube body 61 and the inner tube body 62, and the conveying screw shaft 63 is located in the inner tube body 62 to rotate, and the cold water forms a cold flow in the flow channel 67. The flow cycle completes the transmission and cooling of the purple sweet potato powder. After the preliminary cooling of the water-cooled cooling, the temperature of the purple sweet potato powder finally produced through the air-cooled conical box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com