Fly ash treatment method for waste incineration

A waste incineration fly ash and treatment method technology, applied in the field of environmental engineering, can solve problems such as heavy metal leakage, secondary pollution, and lower performance of asphalt, and achieve the effects of improving strength, reducing pollution, and reducing release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0025] The present embodiment takes by weighing 500g of waste incineration fly ash, takes by weighing 250g of tap water, forms waste incineration fly ash mortar after stirring evenly, adds organic sulfur TMT15 in the mortar, because heavy metal content is higher (such as Pb: 1600mg / kg; As: 650mg / kg; Cd: 380mg / kg), the mass of organic sulfur TMT15 is 25g, stir for 10 minutes, add disodium hydrogen phosphate and calcium oxide, disodium hydrogen phosphate and calcium oxide to the stabilized mortar The molar ratio is 1:1, the mass sum of disodium hydrogen phosphate and calcium oxide is 150g, stir for 10 minutes, add ferric chloride in the mortar after solidification treatment, the mol ratio of ferric chloride and disodium hydrogen phosphate is 1:5, uniformly stirred for 5 minutes, placed the waste incineration fly ash slurry in a plastic mold, and maintained it for 7 days at room temperature and 95% humidity. The compressive strength and leaching toxicity tests were carried out on...

Embodiment 1

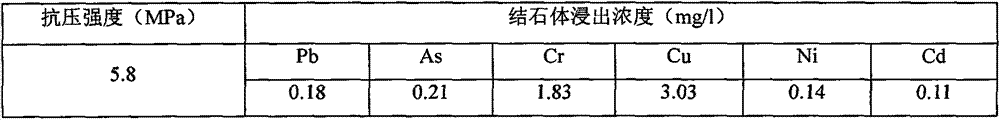

[0026] Example 1 Waste incineration fly ash solidified body test results Table 1

[0027]

Embodiment example 2

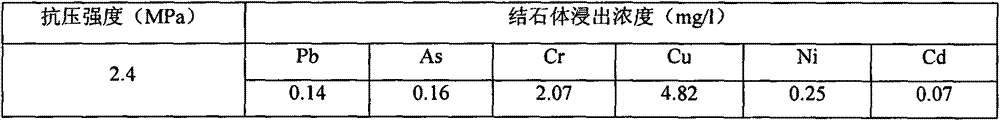

[0029] The present embodiment takes by weighing 500g of waste incineration fly ash, takes by weighing 250g of tap water, forms waste incineration fly ash mortar after stirring evenly, adds organic sulfur TMT15 in the mortar, because the heavy metal content in the fly ash is low (as Pb: 530mg / kg; As: 150mg / kg; Cd: 97mg / kg), the mass of organic sulfur TMT15 is 10g, stir for 10 minutes, add disodium hydrogen phosphate and calcium oxide, disodium hydrogen phosphate and calcium oxide to the stabilized mortar The molar ratio is 1:1, the mass sum of disodium hydrogen phosphate and calcium oxide is 50g, stir for 10 minutes, add ferric chloride in the mortar after solidification treatment, the mol ratio of ferric chloride and disodium hydrogen phosphate is 1:5, stirred evenly for 5 minutes, placed the waste incineration fly ash slurry in a plastic mold, and maintained it for 3 days at room temperature and 95% humidity. The compressive strength and leaching toxicity tests were carried o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com