Combined plasma equipment

A plasma and combined technology, which is applied in the field of exhaust gas purification, can solve the problems of secondary pollution, difficulty in meeting environmental protection requirements, and large exhaust gas emissions, and achieve the effects of strengthening purification capabilities, improving energy utilization, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

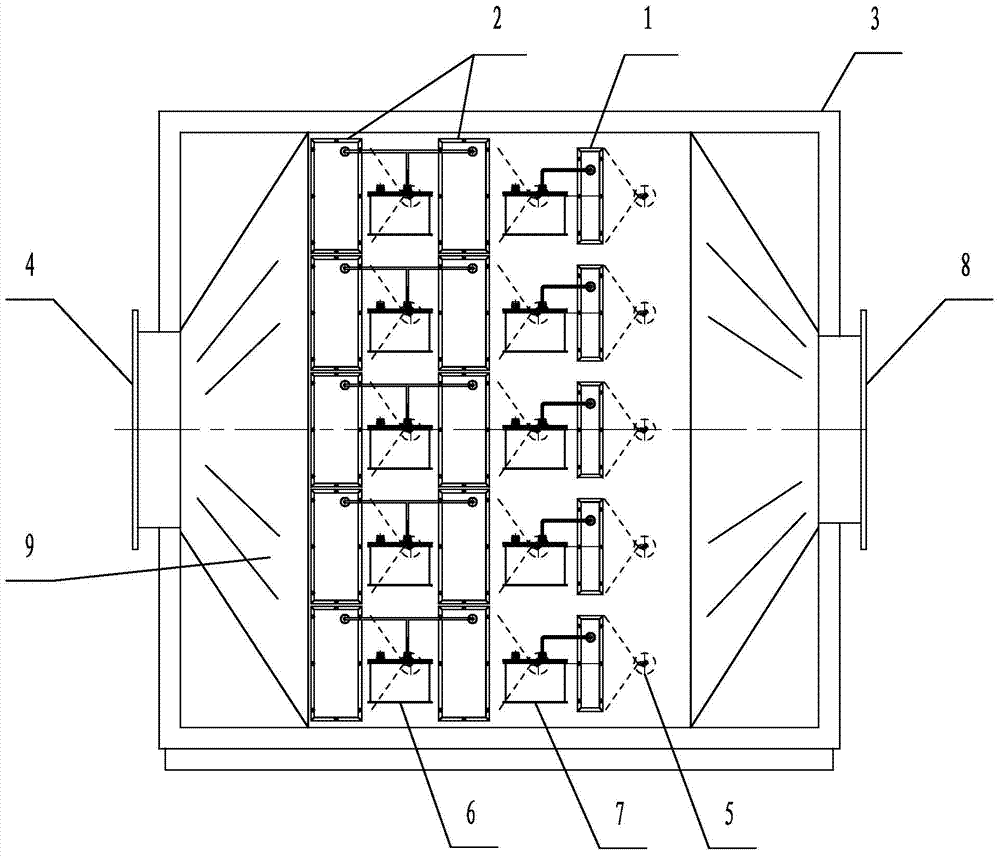

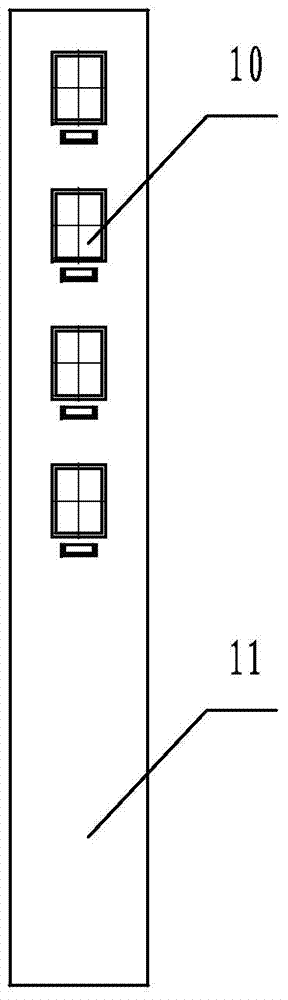

[0024] like figure 1 , figure 2 As shown, a combined plasma device includes a casing 3, an air inlet 4 and an air outlet 8, and also includes: a corona discharge system, a double dielectric barrier discharge low-temperature plasma system, a power supply system, a high-voltage conversion system, and an air distribution and diversion system 9. Spray flushing system.

[0025] Among them, the corona discharge system includes a plurality of corona discharge discs 2, which are provided with positive and negative electrodes, and are externally connected with a high-voltage direct current power supply. The plate-type precipitation electrode is grounded, and the negative pole of the power supply is output to the discharge electrode placed in the center of the plate-shaped electrode. The corona section uses the principle of electrostatic capture to firstly remove particulate matter and mist water droplets in the exhaust gas.

[0026] The dual-dielectric barrier discharge low-tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com