Rapid prototyping system and method for high-precision ester cured water glass sand mold/core

A molding method and technology for solidifying water, applied in the directions of cores, mold components, casting molding equipment, etc., can solve the problems of poor preparation effect, low manufacturing accuracy, and difficulty in recycling old sand, and improve the reuse rate. , the effect of reducing processing energy consumption and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

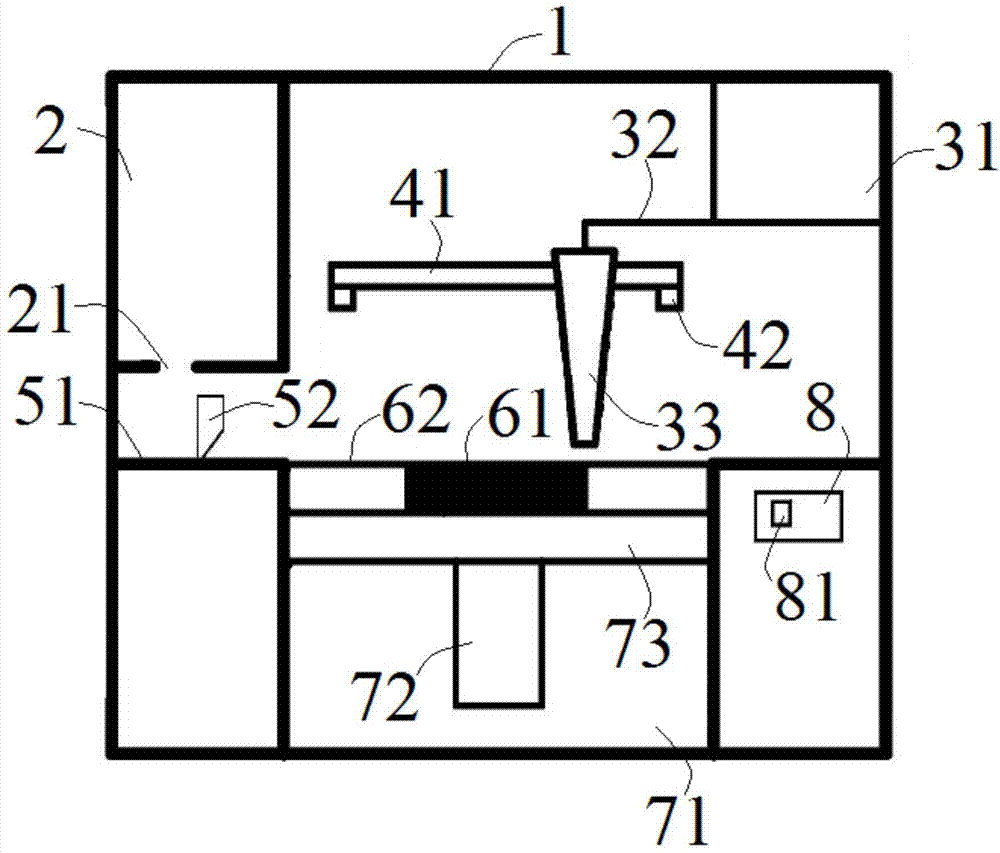

[0037] see figure 2, a rapid prototyping system for a high-precision ester-cured water glass sand mold / core of this embodiment, including a box body 1, a mixing device 2, a liquid dispensing bin 31, a dripping device 33, a material spreading device 52, and a lifting table 73 and controller 8. The mixing device 2 and the liquid dispensing bin 31 are respectively arranged on the upper parts of the two sides of the box body 1, wherein the mixing device 2 is equipped with molding / core sand and water glass, and the mixing device 2 is used to mix the molding / core sand and water glass. Core sand and water glass are thoroughly mixed. The bottom of the mixing device 2 is provided with a discharging port 21 , and a receiving table 51 is arranged below the discharging port 21 , and the mixed material 62 that is mixed evenly falls onto the receiving table 51 from the discharging port 21 . The material spreading device 52 is located below the material outlet 21 and above the material re...

Embodiment 2

[0046] A rapid prototyping system for a high-precision ester-cured water glass sand mold / core of the present embodiment is basically the same as that of Example 1, and its molding process is briefly described as follows:

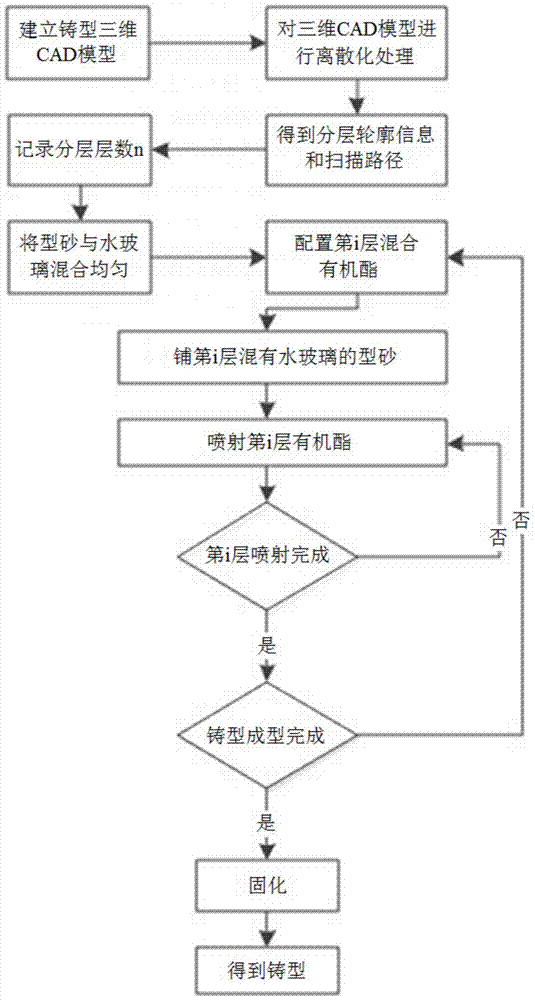

[0047] (1) Establish the CAD geometric entity model of the sand mold / core, and perform layered discrete, generate the running track file of the dripping device for each discrete layer, and import it into the controller of the dripping device through the data interface, and record the number of discrete layers n.

[0048] (2) Mix 80 parts of 70 / 140 mesh mullite sand with 5 parts of water glass with a modulus of 2.5 in a mixing device.

[0049] (3) Spread the mixed mold / core sand coated with water glass on the lifting worktable with a spreading device.

[0050] (4) The compound organic ester of glycerol diacetate and glycerol monoacetate is dropped by the dripping device according to the running track of the first discrete layer generated by the host computer...

Embodiment 3

[0053] A rapid prototyping system for a high-precision ester-cured water glass sand mold / core of the present embodiment is basically the same as that of Example 1, and its molding process is briefly described as follows:

[0054] (1) Establish the CAD geometric entity model of the sand mold / core, and perform layered discrete, generate the running track file of the dripping device for each discrete layer, and import it into the controller of the dripping device through the data interface, and record the number of discrete layers n.

[0055] (2) Mix 120 parts of 70 / 140 mesh olivine sand and 4 parts of water glass with a modulus of 1.8 in a mixing device.

[0056] (3) Spread the mixed mold / core sand coated with water glass on the lifting table with a spreading device.

[0057] (4) The compound organic ester mixed with diethylene glycol diacetate, glycerol monoacetate and ethylene glycol monoacetate is dropped by the dripping device according to the running track of the first dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com