Method of directly implementing dip-pen nanolithography on hydrophobic substrate

A hydrophobic substrate and nanotechnology, applied in nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve problems such as limiting application fields, achieve the effects of expanding application fields, reducing packaging costs, and saving manufacturing time and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

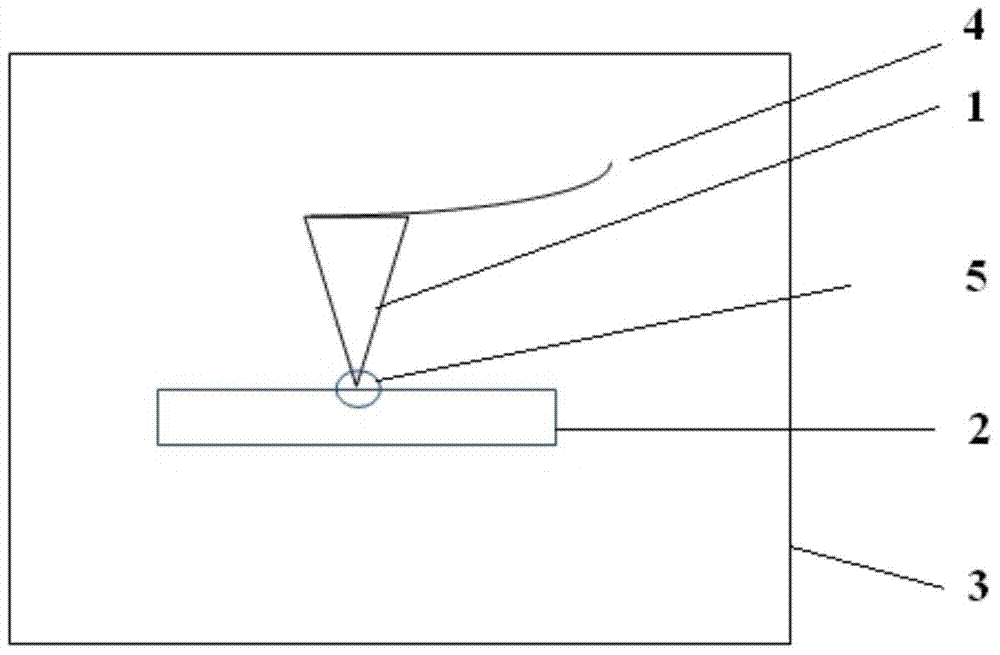

Image

Examples

Embodiment 1

[0023] Using the NP-S type AFM tip, the dip pen nano-etching technique was implemented in toluene saturated vapor. The hydrophobic substrate employed was graphite, the force was 20 nN, and the ink was polymethyl methacrylate. When the needle tip stayed on the graphite surface for 10 seconds, the needle tip was lifted up and imaged, and a smooth bright spot appeared on the graphite surface, indicating that the nanostructure was successfully prepared.

Embodiment 2

[0025] Using the NSC-18 AFM tip, the dip pen nano-etching technique was implemented in ethanol saturated vapor. The hydrophobic substrate used is polydimethylsiloxane and the ink is polyvinylpyrrolidone. The residence time of the needle tip on the substrate surface was 10 seconds, and the applied force was 20 nN. Then lift the needle tip and image it, you can see a smooth bright spot on the surface of the substrate, indicating that the nanostructure has been successfully prepared.

Embodiment 3

[0027] Using the NSC-18 AFM needle tip, the dip pen nano-etching technique was implemented in the saturated vapor of ethanol / water 1:1. The hydrophobic base used is polydimethylsiloxane and the ink is polyethylene glycol. The residence time of the needle tip on the substrate surface was 10 seconds, and the applied force was 20 nN. Then lift the needle tip and image it, you can see a smooth bright spot on the surface of the substrate, indicating that the nanostructure has been successfully prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com