Diatomite capable of controlling humidity absorbing and releasing performance by illumination and preparation method thereof

A technology of light control and diatomite, which is applied in the field of diatomite, can solve problems such as poor humidity control effect, and achieve the effect of simple preparation method and scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

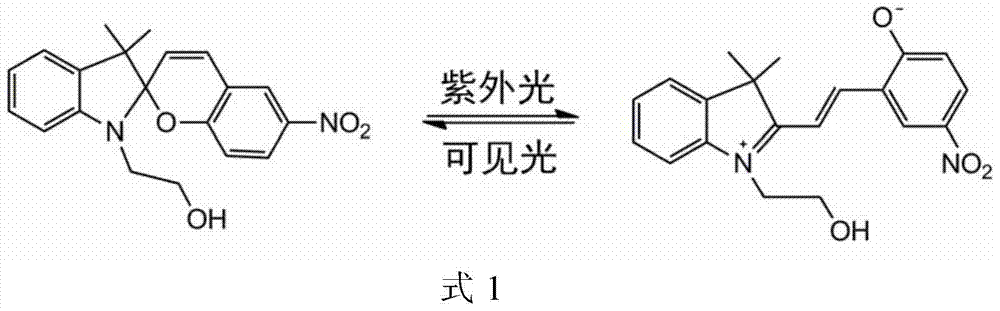

[0025] This embodiment discloses a diatomite whose moisture absorption and desorption performance is controlled by light, and its moisture absorption and desorption performance can be controlled by light conditions. The preparation method steps are as follows:

[0026] Put 500g of diatomite minerals from a certain place in Inner Mongolia in a furnace and raise the temperature to 650°C at a rate of 10°C / min and keep it warm for 2 hours to remove the residual organic matter on the surface. The analysis is as shown in Table 1:

[0027] Table 1 X-ray fluorescence spectroscopy (XRF) analysis results

[0028] chemical composition SiO 2 Al 2 o 3 Fe 2 o 3 K 2 o MgO CaO TiO 2 Na 2 o MnO Mass % 76.6 12.4 6.4 1.9 1.0 0.7 0.5 0.4 0.1

[0029] The above diatom cooled soil was placed in a toluene solution of 5% (v / v) aminopropyltriethoxysilane at 80° C. for 6 hours for amination, and then filtered and washed with ethanol.

[0030] Add...

Embodiment 2

[0033] This embodiment discloses a diatomite whose moisture absorption and desorption performance is controlled by light. The preparation method steps are as follows: the object of modification is a ceramic decorative brick with moisture absorption and desorption function prepared by sintering at high temperature using diatomite as a raw material. The mass of unmodified ceramic decorative tiles increases by 6.2% after being placed at 27°C and 83RH% relative humidity for 24 hours, and the mass decreases by 5.4% after being placed at 27°C and 33RH% relative humidity for 24 hours.

[0034] Cut ceramic decorative tiles to 100×100mm 2 And placed in anhydrous toluene solution of 5% (v / v) aminopropyltriethoxysilane, refluxed at 80° C. for 10 hours for amination, then dried in the air and washed with ethanol alternately for 3 times.

[0035] Add the aminated ceramic tiles to carboxypropyl-3,3 dimethyl-6 nitroindoline spiropyran 5%wt ethanol solution, stir and soak for 3 hours, and dry...

Embodiment 3

[0038] This embodiment discloses a diatomite whose moisture absorption and desorption properties are controlled by light. The preparation method steps are as follows: put the diatomite raw ore in a furnace to raise the temperature to 700° C. and keep it warm for 3 hours to remove residual organic matter on the surface.

[0039] Diatomaceous earth and aminopropyltriethoxysilane were placed in n-hexane, refluxed at 70°C for 12 hours, filtered and washed with ethanol. The amount of solvent required for the reflux meets the stirring requirement or immerses the diatomaceous earth. The consumption ratio of described diatomite and silane coupling agent is 1kg: 50ml;

[0040] Soak and stir the diatomite grafted with amino groups in an ethanol solution containing carboxypropyl-3,3 dimethyl-6 nitroindoline spiropyran, the surface of the diatomite grafted with spiropyran The number of spiropyran switch molecules is controlled by the soaking time. In order to realize the switch of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com