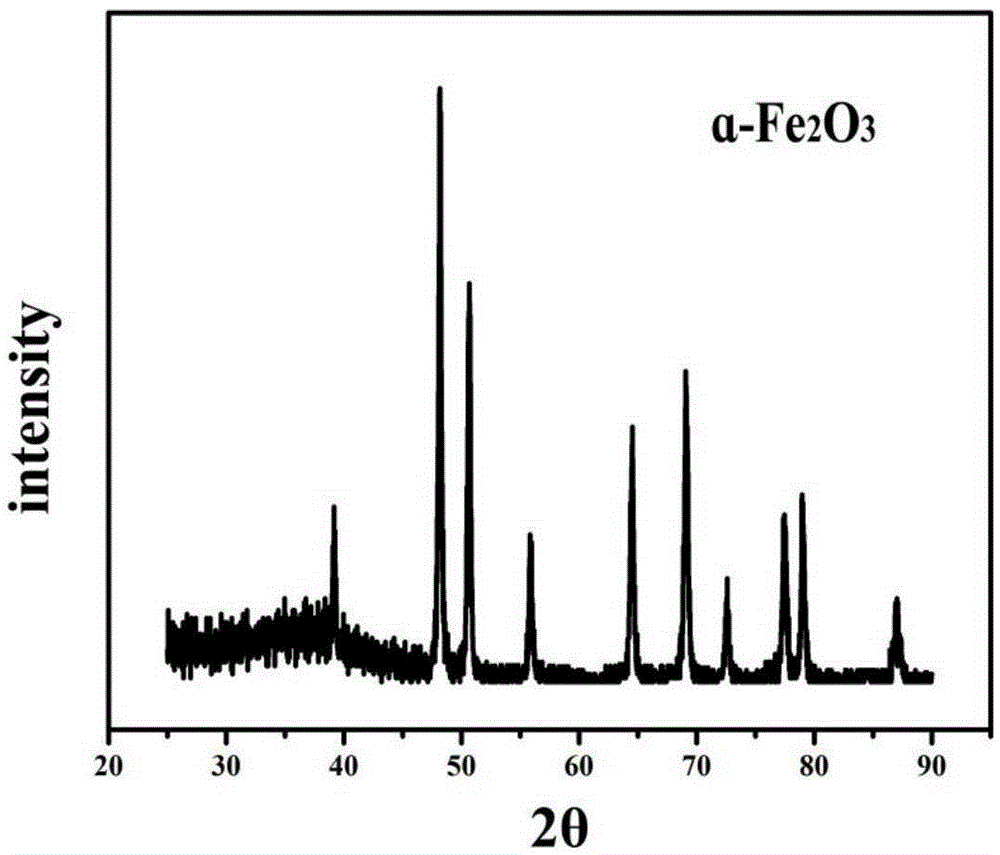

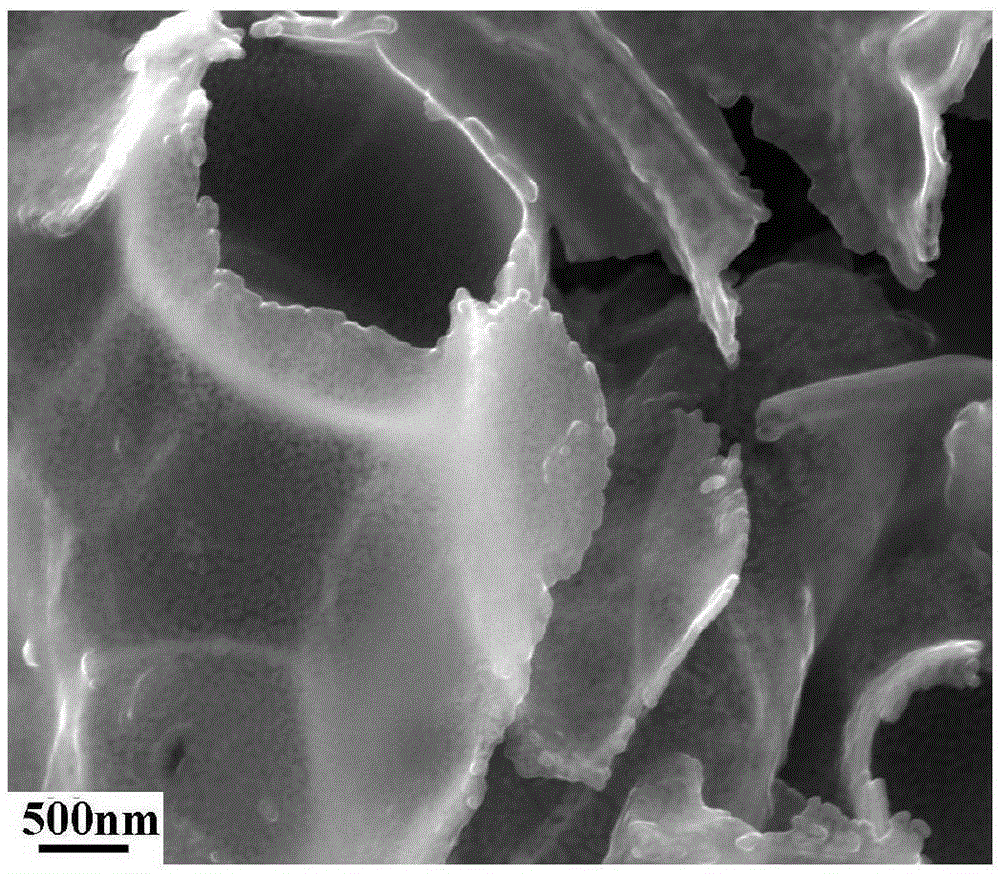

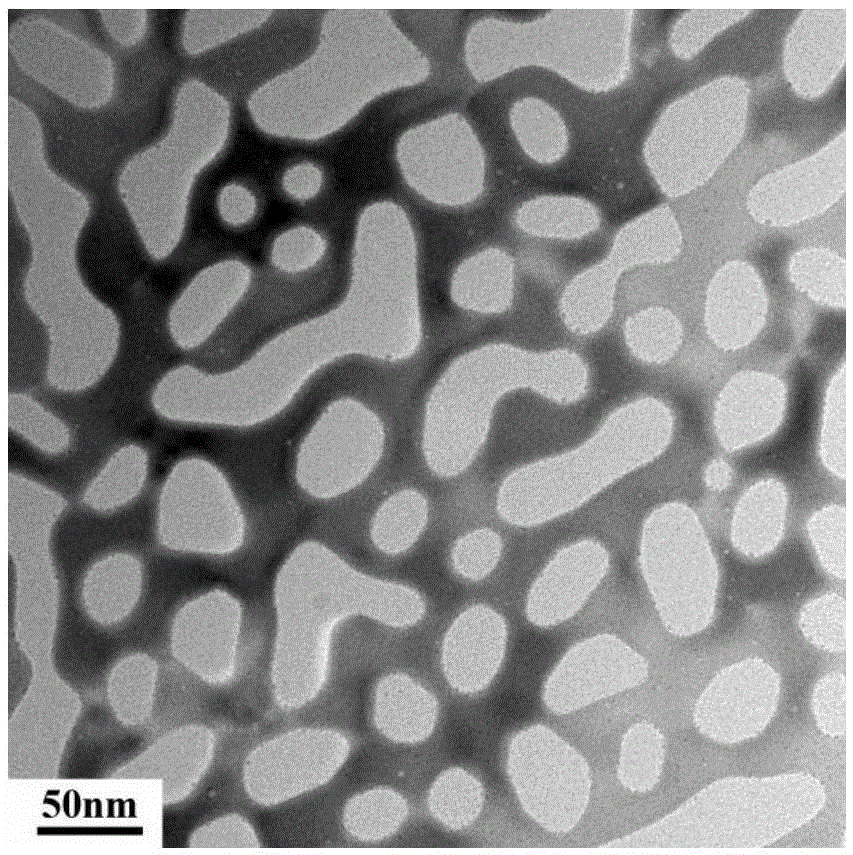

A kind of method for preparing nanoporous iron oxide powder

A technology of iron oxide powder and nanopores, which is applied in the field of excessive metal oxide porous materials, can solve the problems of difficult uniform mixing of pore-forming agents and aggregates, difficult removal of templates, and uneven distribution of pores, etc., to achieve nano-pore structure Good, low cost, high reactivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 0.025 moles of ferric nitrate, 0.07 moles of glycine, and 0.0375 moles of glucose (carbon source), and dissolve various raw materials in deionized water to prepare a solution; After a series of reactions such as , decomposition, etc., the precursor powder is obtained; in the air atmosphere, after the furnace temperature rises to 500°C, the precursor powder is placed in the furnace for heat treatment for 0.5h, and the nanoporous iron oxide powder is obtained.

Embodiment 2

[0028] Weigh 0.025 moles of ferric nitrate, 0.03 moles of glycine, and 0.05 moles of sucrose (carbon source), and dissolve various raw materials in deionized water to prepare a solution; After a series of reactions such as , decomposition, etc., the precursor powder is obtained; in the air atmosphere, after the furnace temperature rises to 500°C, the precursor powder is placed in the furnace and kept for 0.5h to obtain nanoporous iron oxide powder.

Embodiment 3

[0030] Weigh 0.025 moles of ferric nitrate, 0.04 moles of glycine, and 0.07 moles of maltose (carbon source), dissolve various raw materials in deionized water, and prepare a solution; place the solution on a temperature-controllable electric furnace to heat, and the solution undergoes volatilization, concentration After a series of reactions such as , decomposition, etc., the precursor powder is obtained; in the air atmosphere, when the furnace temperature rises to 600 ° C, the precursor powder is placed in the furnace for 1 hour to obtain nanoporous iron oxide powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com