Method for preparing iron oxide red and manganese carbonate by using titanium white waste acid

A technology of titanium dioxide waste acid and iron oxide red, applied in chemical instruments and methods, iron oxide, iron oxide/iron hydroxide, etc., can solve the problem that the product quality cannot meet the high quality requirements, the waste acid cannot be utilized, and the stability cannot be Large-scale production and other problems, to achieve the effect of reuse, short reaction time and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

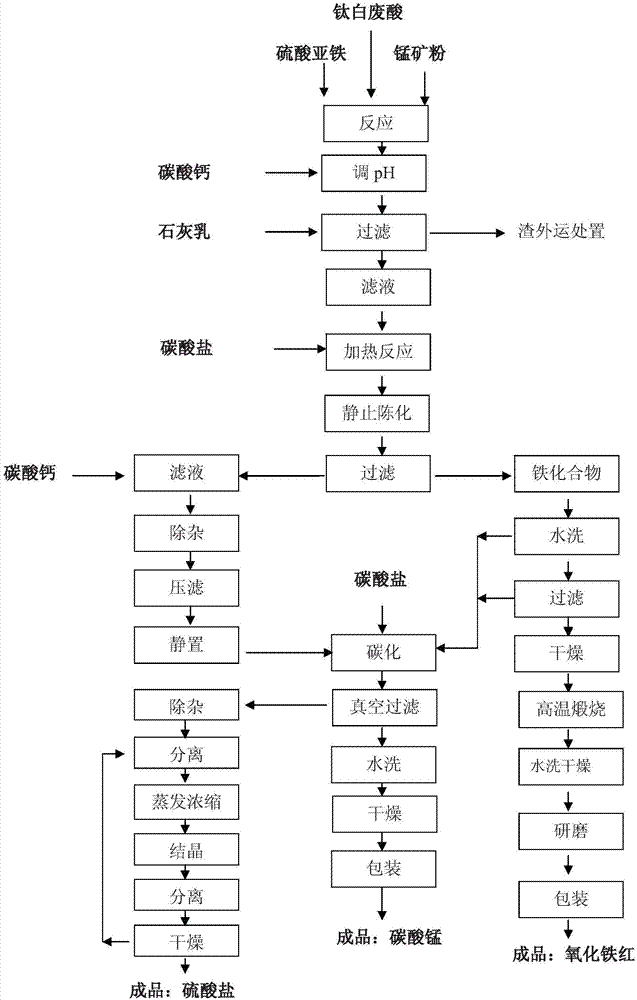

[0030] A method for producing iron oxide red and manganese carbonate by using titanium white waste acid, comprising the following steps:

[0031] 1) Put 25kg FeSO 4 ·7H 2 O adds 43L of titanium dioxide waste acid (H 2 SO 4 concentration 20%), add 25.5 kg of pyrolusite with a manganese content of 12%, react until the pH of the solution is 1 to 1.5, and filter;

[0032] 2) adding calcium carbonate to the filtrate obtained in step 1) to adjust the pH value to 1.5-2, filtering, adding lime milk to the filter residue to neutralize and discarding;

[0033] 3) add ammonium bicarbonate to the filtrate obtained by filtering in step 2) to adjust the pH value to 2-2.5, keep the temperature at 75-95°C during the reaction, and keep it warm for 2-4 hours;

[0034] 4) Step 3) standing and aging for 12 hours, a large amount of iron-containing intermediate products precipitated, filtered;

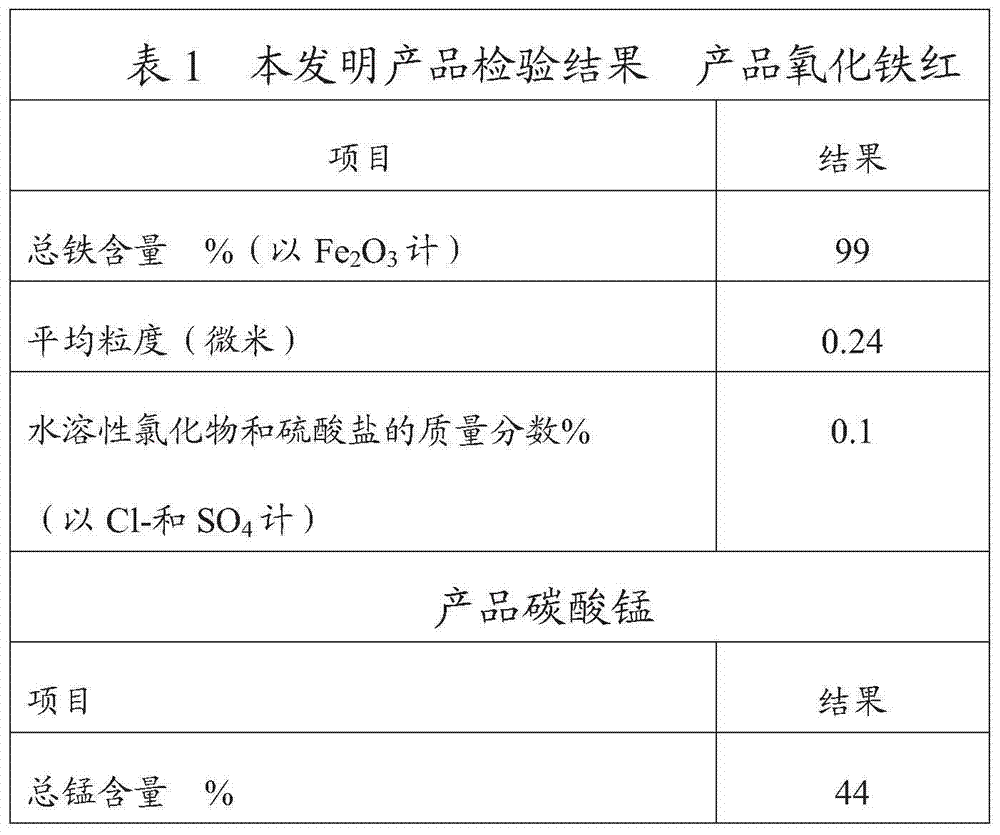

[0035] 5) Wash the filter residue obtained in step 4) with water for 1 to 5 times, dry at 100 to 12...

Embodiment 2

[0040] 1) Put 25kgFeSO 4 .7H 2 O adds 43L of titanium dioxide waste acid (H 2 5O 4 concentration 20%), add 20 kg of pyrolusite with a manganese content of 15%, react until the pH value of the solution is 1 to 1.5, obtain ferric iron and divalent manganese, and filter;

[0041] 2) adding calcium carbonate to the filtrate obtained in step 1) to adjust the pH value to 1.5-2, filtering, and adding lime milk to the filter residue to neutralize and transport for disposal;

[0042] 3) adding ammonium carbonate to the filtrate obtained by filtering in step 2) to adjust the pH value to 2-2.5, keeping the temperature at 75-95° C. during the reaction, and keeping it warm for 2-4 hours;

[0043] 4) Step 3) standing and aging for 12 hours, a large amount of iron-containing intermediate products precipitated, filtered;

[0044] 5) Wash the filter residue obtained in step 4) with water for 1-5 times, dry at 100-125°C to obtain a powdery intermediate product, then calcinate the powdery in...

Embodiment 3

[0048] 1) Put 20kg FeSO 4 ·7H 2 O add 35L of titanium dioxide waste acid (H 2 SO 4concentration 20%), add 20.5 kg of pyrolusite with a manganese content of 12%, react until the pH value of the solution is 1 to 1.5, and filter;

[0049] 2) adding calcium carbonate to the filtrate obtained in step 1) to adjust the pH value to 1.5-2, filtering, adding lime milk to the filter residue, neutralizing and transporting for disposal;

[0050] 3) Add sodium carbonate to the filtrate obtained by filtering in step 2) to adjust the pH value to 2-2.5, keep the temperature at 75-95°C during the reaction, and keep it warm for 2-4 hours;

[0051] 4) Step 3) After standing and aging for 12 hours, a large amount of iron-containing intermediate products precipitated and filtered;

[0052] 5) Wash the filter residue obtained in step 4) with water for 1 to 5 times, dry at 100 to 125°C to obtain 13 kg of powdery intermediate product, then calcinate the powdery intermediate product at 600 to 800°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com