Boiler make-up water purification system

A technology for making up water and boilers, applied in descaling and water softening, water/sewage treatment, general water supply saving, etc., can solve problems such as boiler scaling, easy scaling of boilers, lower heat utilization rate, etc., to avoid oxidation damage , Avoid crystallization and improve water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

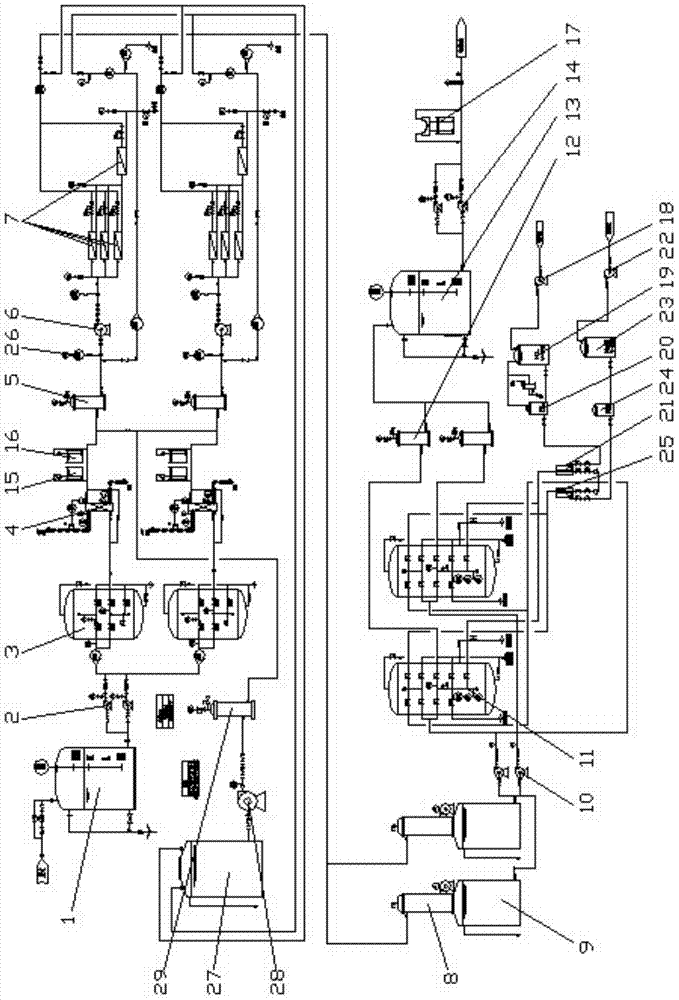

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0019] As shown in the figure, the boiler feed water purification system in this embodiment includes a raw water tank 1, a raw water pump 2, a multimedia filter 3, a heat exchanger 4, a security filter 5, a high-pressure pump 6, and a reverse Osmosis system 7, carbon remover 8, water tank 9 arranged at the lower part of the carbon remover, mixed bed water pump 10, ion exchange mixed bed 11, particulate filter 12, desalted water tank 13 and desalted water pump 14;

[0020] It also includes a dosing system arranged between the heat exchanger and the security filter, and the dosing system includes an antiscalant adding system 15 and a NaHSO adding system 16;

[0021] It also includes an ammonia addition system 17 arranged at the water outlet of the desalinated water pump.

[0022] In the boiler feed water purification system of this embodiment, the multi-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com