Piezoelectric composite material and preparation method thereof

A technology of piezoelectric composite materials and pressure-sensitive materials, applied in the field of three-phase composite materials of polyvinylidene fluoride (PVDF) and pressure-sensitive ceramics, piezoelectric ceramics, can solve the problem of low polarization resistance, easy breakdown, pressure Poor electrical performance and other issues, to achieve the effect of low cost, promote migration, and increase coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] PLZT is prepared by the traditional solid-state method. According to the stoichiometric ratio, the piezoelectric ceramic sheet is prepared through mixing, pre-firing, film rolling, punching, debinding, and firing. Its properties are: ε 33 t / ε 0 =2000±250, tanδ=1.5%~3.0%, d 33 >300 pC / N, vibrate the ceramic sheet in a vibrating mill, pass through different mesh sieves, and prepare PLZT ceramic powders of different particle sizes for use.

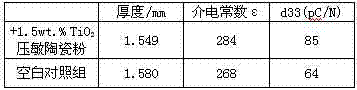

[0024] Will account for 1.5% of the total weight of PLZT and PVDF mixture of TiO 2 Add pressure-sensitive ceramic powder into a stainless steel cup, add alcohol for ultrasonic dispersion for 5 minutes, add PVDF powder with a mass fraction of 4.7% for ultrasonic dispersion for 15 minutes, and then add 250-300 mesh piezoelectric ceramic powder with a mass fraction of 95.3% for electric stirring and evaporation of alcohol. Three-phase blend powder. A disc with a diameter of 17.6 mm and a thickness of 2 mm was prepared by dry pressing...

Embodiment 2

[0028] The preparation method of PLZT ceramic powder is the same as embodiment 1.

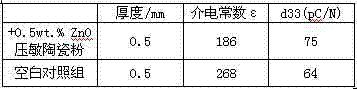

[0029] Add 0.5% ZnO pressure-sensitive ceramic powder accounting for the total weight of the PLZT and PVDF mixture into a stainless steel cup, add a certain amount of dispersant, and after ultrasonic dispersion for 1 hour, add PVDF with a mass fraction of 4.7%, and wait until the PVDF is completely dissolved , adding PLZT ceramic powder with a mass fraction of 95.3%, electric stirring for 4 hours, rotary evaporation to the required viscosity, pouring it into a self-made casting device, scraping and drying to obtain a film with a thickness of 0.2~0.4 mm, and superimposing two layers of film The composite film was prepared by hot pressing on a flat vulcanizer, and the composite film was punched to make a circular piezoelectric composite sheet with a diameter of 8.9 mm and a thickness of 0.4-0.6 mm. The hot pressing conditions were: hot pressing temperature 180 °C, pressure 10 Mpa, holding time 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com