Preparation method of substrate with high temperature resistant hydrophobic conductive coating

A conductive coating and high-temperature-resistant technology, which is applied in the field of substrate preparation, can solve the problems of easy contamination, poor high-temperature resistance, and insufficient conductivity to meet the conductivity, and achieves a simple preparation process, low cost, and easy access. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described by examples below.

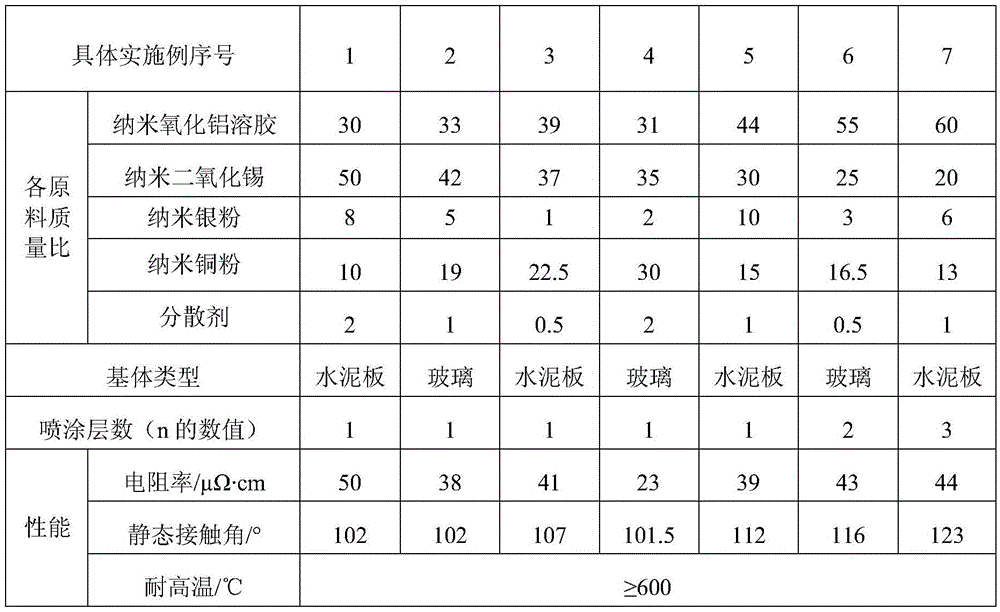

[0021] The alumina sol composite slurry in the present invention is mixed with the following raw materials in weight percentage: nano tin dioxide 20-50%, nano alumina sol 30-60%, nano silver powder 5-10%, nano Copper powder 10-30% and dispersant 0.5-2%.

[0022] In this embodiment, the nano-tin dioxide is selected from Shanghai Jingchun Biochemical Technology Co., Ltd. with a purity of 99.99% and a particle size of 50-70 nm; the nano-alumina sol is selected from the mass concentration produced by Hefei Xiangzheng Chemical Technology Co., Ltd. It is 20-25% of the product, the particle size is 10-20nm; the nano silver powder is made of silver nitrate (analytical purity, molecular weight: 169.87, Sinopharm Chemical Reagent Co., Ltd.) and glucose (analytical purity, molecular weight: 198.17, Sinopharm Chemical Reagent Co., Ltd. The company) is prepared by a reduction reaction at 25°C with a particle size of 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com