Low-temperature-curing polyester resin for powder paints, powder paint using resin and preparation method thereof

A technology of powder coating and polyester resin, applied in the direction of powder coating, polyester coating, coating, etc., can solve the problems of application limitation, increase energy consumption, affect production efficiency, etc., reduce consumption and waste, and expand application fields , the effect of meeting the requirements of industrial scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

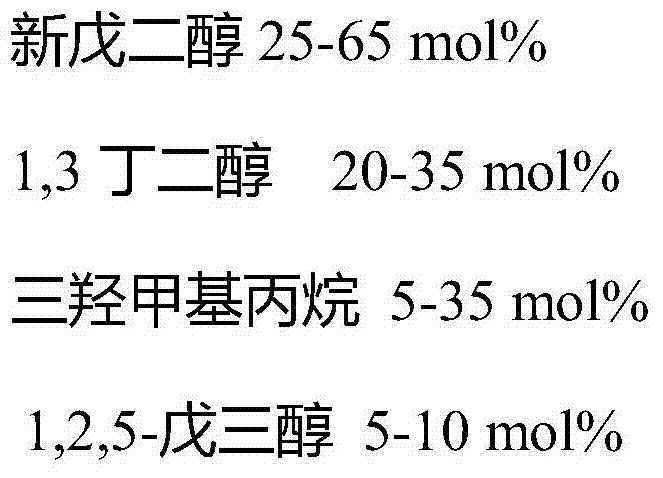

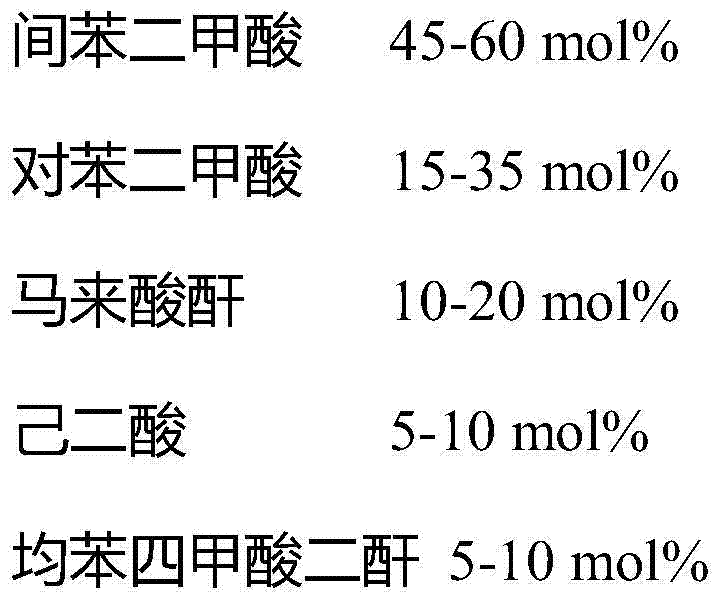

[0025] A low-temperature curing polyester resin for powder coatings, the composition and molar ratio of its raw materials are: 6.5 mol of neopentyl glycol, 2 mol of 1,3-butanediol, 0.5 mol of trimethylolpropane, 1,2,5 - Pentatriol 1mol, isophthalic acid 6.4mol, terephthalic acid 2.2mol, maleic anhydride 1.1mol, adipic acid 0.55mol, pyromellitic dianhydride 0.77mol, monobutyltin oxide 0.015mol, anti Oxidant 1010 0.01mol.

[0026] The preparation method of low-temperature curing type polyester resin for powder coating comprises the following steps:

[0027] A, the neopentyl glycol of formula quantity, 1,3 butanediol, trimethylolpropane, 1,2,5-pentanetriol are added in the there-necked flask that stirring and reflux condenser tube are housed, mix and stir and Heating and melting below 130°C;

[0028] B. Adding isophthalic acid, terephthalic acid, maleic anhydride and adipic acid in the above-mentioned mixed alcohol, and adding 0.1-0.2% monobutyltin oxide of the total amount of ...

Embodiment 2-4 and comparative example 1-2

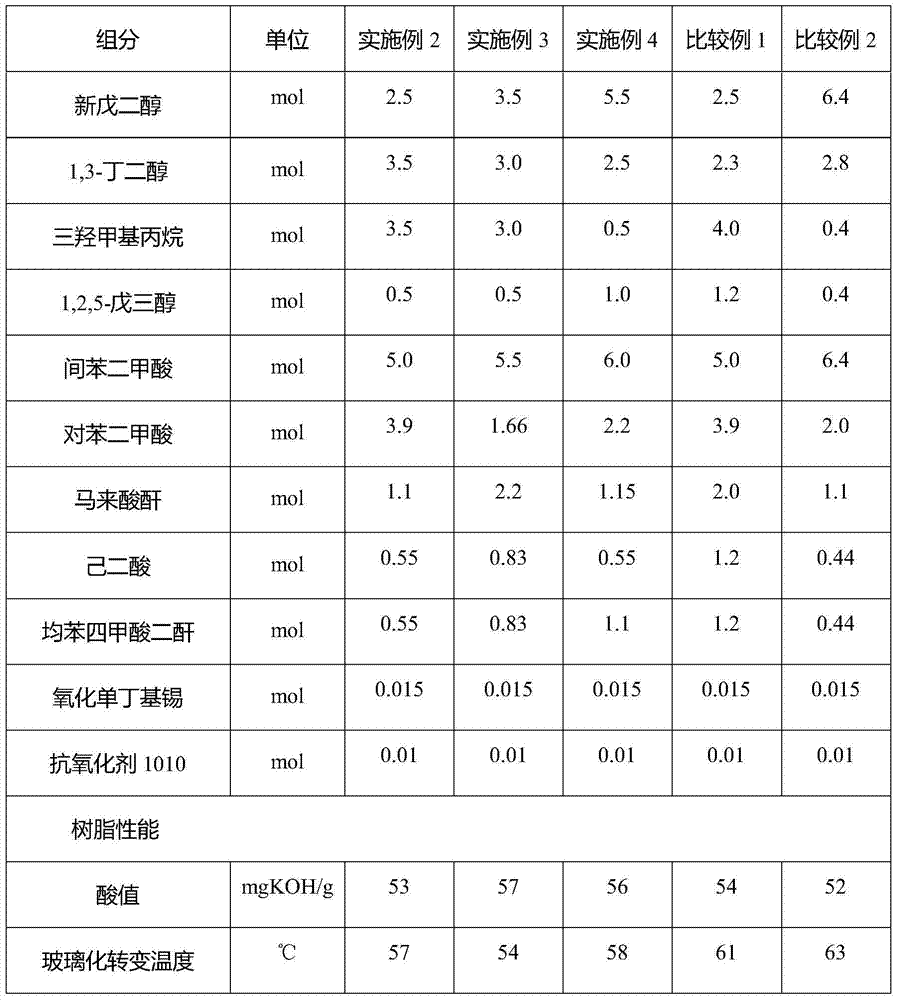

[0032] According to the formulation amounts listed in Table 1 below, the polyester resins of Examples 2-4 and Comparative Examples 1-2 were obtained according to the same preparation method as Example 1.

[0033] Table 1 Composition and properties of polyester resin

[0034]

[0035]

[0036] As can be seen from Table 1, the glass transition temperatures of the polyester resins of Examples 2-4 are all lower than Comparative Examples 1-2 whose raw material content is not within the scope of the present invention; in addition, the softening point is also lower than that of Comparative Example 1 and 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com