Softening technology and equipment for polysaccharides lyophilized sponge dressing

A technology of polysaccharide and chemical equipment, which is applied in the field of softening process and equipment, can solve the problems of poor compliance, low density of polysaccharide sponge, poor water absorption and water retention, etc., and achieves good resilience and compliance, and stable wet state. Good sex and diverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

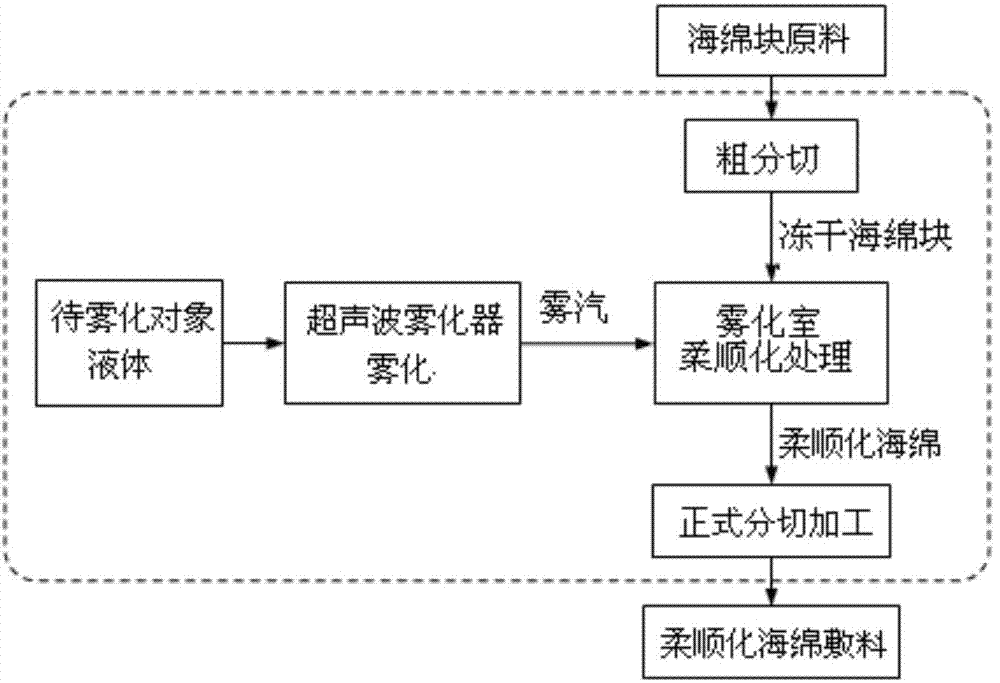

[0030] The softening process of the polysaccharide freeze-dried sponge dressing provided by the invention, its technological process is as follows figure 1 shown, including the following steps:

[0031] (1) The polysaccharide freeze-dried sponge block raw material is roughly cut to obtain a freeze-dried sponge block. The length of the freeze-dried sponge block is 10 cm, and the width is 10 cm. The polysaccharide freeze-dried sponge is made of an aqueous solution of chitosan It is prepared by mixing acetic acid and medical fungicide, after mold shaping, freezing and freeze-drying;

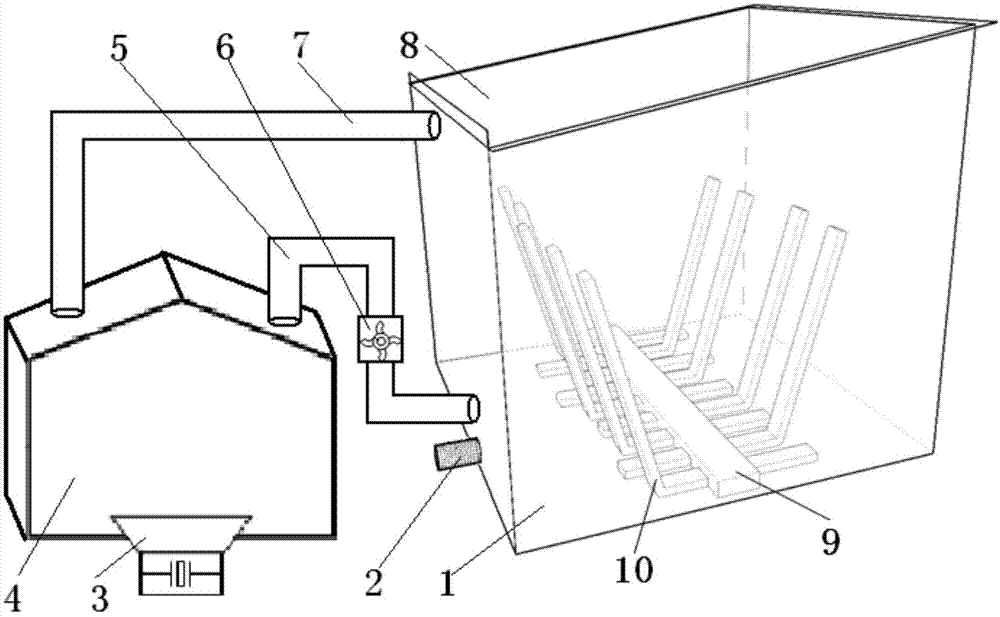

[0032] (2) Use an ultrasonic atomizer to atomize pure water into fine liquid droplets, collect the fine liquid droplets to form mist, and pass the mist into the sealing device to circulate the mist between the ultrasonic atomizer and the sealing device ;

[0033] (3) Put the freeze-dried sponge block into a sealing device filled with mist and process it for 0.5 minutes, make the freeze-dried spong...

Embodiment 2

[0036] The softening process of the polysaccharide freeze-dried sponge dressing provided by the invention, its technological process is as follows figure 1 shown, including the following steps:

[0037] (1) The raw material of the polysaccharide freeze-dried sponge block is roughly cut to obtain the freeze-dried sponge block. The length of the freeze-dried sponge block is 40 cm, and the width is 40 cm. The polysaccharide freeze-dried sponge is composed of an aqueous solution of chitosan It is prepared by mixing acetic acid and medical fungicide, after mold shaping, freezing and freeze-drying;

[0038] (2) Use an ultrasonic atomizer to atomize the hemostatic agent into fine liquid droplets, collect the fine liquid droplets to form mist, and pass the mist into the sealing device, so that the mist circulates between the ultrasonic atomizer and the sealing device ;

[0039] (3) Put the freeze-dried sponge block into a sealed device filled with mist for 30 minutes, make the freez...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com