Antibacterial deodorant sponge insole and manufacture method thereof

A production method and a technology for insole, which are applied in the field of shoe-making production, can solve the problems of inability to kill bacteria and fungi, and achieve the effect of significant antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

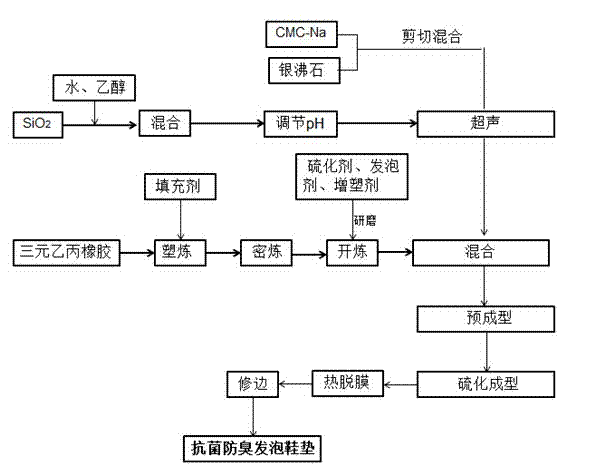

Image

Examples

Embodiment 1

[0033] An antibacterial and deodorant foaming insole, the foaming insole includes the following materials by weight:

[0034] EPDM rubber: 100 parts

[0035] Vulcanizing agent: 1 part

[0036] Regulator: 80 parts

[0037] Plasticizer: 40 parts

[0038] Foaming agent: 1 part

[0039] Silver zeolite: 0.5 parts

[0040] Silica gel: 2 parts;

[0041] Its production method is as follows:

[0042] (1) Preparation of silver-loaded zeolite solution: Add 30g of CMC-Na into a beaker of 50mL 3% silver-loaded zeolite aqueous solution, adjust the pH of the system to 8.5, then shear at a high speed of 4000rpm for 30min, and set aside;

[0043] (2) 20g of organic matter, after mixing, add 20g of anhydrous sodium carbonate, stir and adjust the pH of the solution to 2.5 with NaOH with a concentration of 0.2mol / L and 10% hydrochloric acid, and then stir with an electric stirrer at 30°C for 3 hours to make The peptization, obtained transparent sol, stand-by;

[0044] (3...

Embodiment 2

[0053] An antibacterial and deodorant foaming insole, the foaming insole includes the following materials by weight:

[0054] EPDM rubber: 100 parts

[0055] Vulcanizing agent: 5 parts

[0056] Regulator: 150 parts

[0057] Plasticizer: 68 parts

[0058] Foaming agent: 5 parts

[0059] Silver zeolite: 2.5 parts

[0060] Silica gel: 8 parts;

[0061] Its production method is as follows:

[0062](1) Preparation of silver-loaded zeolite solution: Add 50g of CMC-Na into a beaker of 50mL 5% silver-loaded zeolite aqueous solution, adjust the pH of the system to 9.5, then shear at a high speed of 4000rpm for 30min, and set aside;

[0063] (2) 15g of organic matter, after mixing, add 25g of anhydrous sodium carbonate, stir and adjust the pH of the solution to 2.5 with NaOH with a concentration of 0.2mol / L and 10% hydrochloric acid, and then stir with an electric stirrer at 30°C for 4 hours to make The peptization, obtained transparent sol, stand-by;

[0064] ...

Embodiment 3

[0073] An antibacterial and deodorant foaming insole, the foaming insole includes the following materials by weight:

[0074] EPDM rubber: 100 parts

[0075] Vulcanizing agent: 3 parts

[0076] Regulator: 110 parts

[0077] Plasticizer: 55 parts

[0078] Foaming agent: 3 parts

[0079] Silver zeolite: 1.5 parts

[0080] Silica gel: 6 parts;

[0081] Its production method is as follows:

[0082] (1) Preparation of silver-loaded zeolite solution: add 48g CMC-Na into a beaker of 40mL 6% silver-loaded zeolite aqueous solution, adjust the pH value of the system to 8.5, then shear at a high speed of 4000rpm for 30min, and set aside;

[0083] (2) 17g of organic matter, after mixing, add 23g of anhydrous sodium carbonate, stir and adjust the pH of the solution to 2.5 with NaOH with a concentration of 0.2mol / L and 10% hydrochloric acid, and then stir with an electric stirrer at 30°C for 4 hours to make The peptization, obtained transparent sol, stand-by;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com