High-rigidity high-fluidity polystyrene composition and preparation method and application thereof

A high-impact polystyrene and high-fluidity technology, applied in the field of high-rigidity and high-fluidity polystyrene compositions and their preparation, can solve the problems of insufficient rigidity or product dimensional accuracy, large Young's modulus, high rigidity, etc. , to achieve good bass effect, improve material density and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

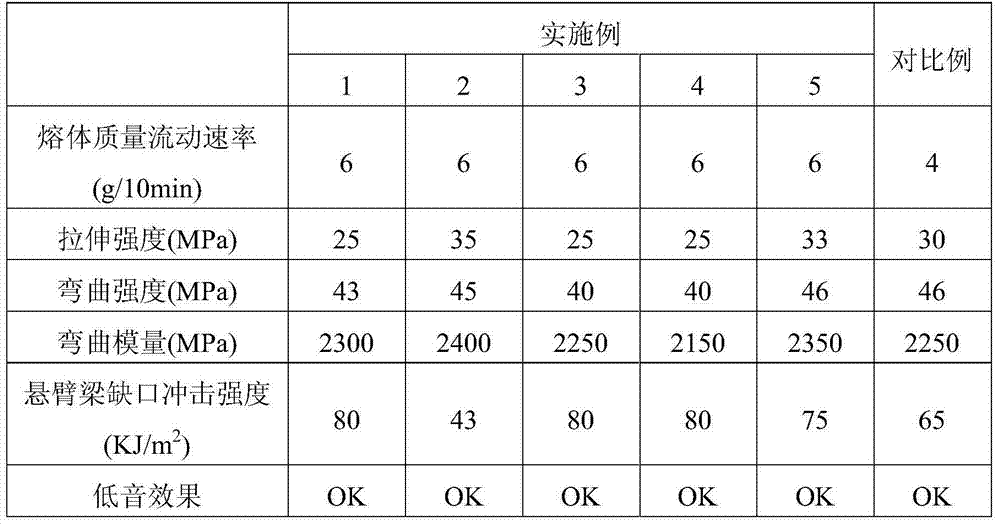

Examples

Embodiment 1

[0037] Example 1: Preparation of high-rigidity and high-fluidity polystyrene composition

[0038] 71wt% high-impact polystyrene (HIPS, 200°C, 5Kg melt index is 4g / min, rubber particle size is 0.5μm), 15wt% transparent polystyrene, 10wt% mineral fillers (calcium carbonate and talc, The particle size is 0.5~1μm) and 4wt% additives (styrene-butadiene rubber toughening agent, molecular weight is 1.0×10 5 , The ratio of styrene to butadiene is: 40 / 60) Put it into a high-speed mixer with a rotation speed of about 1000rpm and mix for 3min, then put it into a twin-screw extruder, the temperature is controlled at: 230℃, the screw speed is 450rpm, Extrusion and granulation can obtain a polystyrene composition with high rigidity and high fluidity.

Embodiment 2

[0039] Example 2: Preparation of high-rigidity and high-fluidity polystyrene composition

[0040] Combine 65wt% high-impact polystyrene (HIPS, 200℃, 5Kg melt index is 3-6g / min, rubber particle size is 1μm), 25wt% transparent polystyrene, 5wt% mineral filler (talc powder, particle size 0.5~1μm) and 5wt% additives (styrene-butadiene rubber toughening agent, molecular weight 2.0×10 5 , The ratio of styrene to butadiene is: 30 / 70) Put it into a high-speed mixer with a rotation speed of about 1000rpm and mix for 3min, then put it into a twin-screw extruder, the temperature is controlled at: 230℃, the screw speed is 450rpm, Extrusion and granulation can obtain a polystyrene composition with high rigidity and high fluidity.

Embodiment 3

[0041] Example 3: Preparation of high rigidity and high fluidity polystyrene composition

[0042] 70wt% high-impact polystyrene (HIPS, 200℃, 5Kg melt index is 6g / min, rubber particle size is 3μm), 12wt% transparent polystyrene, 10wt% mineral filler (talc powder, particle size 0.5 ~1μm) and 8wt% additives (styrene-butadiene rubber toughening agent, molecular weight 2.0×10 5 , The ratio of styrene to butadiene is: 40 / 60) Put it into a high-speed mixer with a rotation speed of about 1000rpm, mix for 3min, and then put it into a twin-screw extruder, the temperature is controlled at 230℃, the screw speed is 450rpm, Extrusion granulation can obtain high rigidity and high fluidity polystyrene composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Financial index | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Financial index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com