Method for preparing light oil from low-hydrogen-content oil with self-contained asphalten

A technology of asphaltene and hydrogen content, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrogenation process, etc., and can solve the problems of poor combustion performance, increased investment, increased energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0114] The medium and low temperature coal tar produced in the coal-to-semi-coke process is shown in Table 1. The annual processing capacity is 500,000 tons / year, the annual operating hours are 7920, and the quantity is 63132kg / h. In order to separate the light residual oil component to the greatest extent, and simultaneously concentrate the asphaltenes, ash, and particulate matter in the coal tar in the heavy coal tar pitch to obtain a high softening point of the coal charcoal, adopt the present invention, and the operation steps are as follows:

[0115] In the deep vaporization separation part STEP1, under the condition that no obvious coking reaction occurs, the raw material F01 is heated and separated into vapor phase V1 (59072kg / h, 93.57% of the raw material F01) and the liquid phase L1 (4060 / h, accounting for 6.43% of the raw material F01) containing the residual oil component, the weight content of the components with a conventional boiling point higher than 500 ° C in t...

Embodiment 2

[0123] Based on Example 1, in the vaporized oil recovery step, the vapor phase V1 from the deep vaporization separation part STEP1 and the stripped oil vapor V2 from the steam stripping part STU are condensed to obtain hydrocarbon oil HPF.

[0124] In the hydrogenation step, the hydrocarbon oil HPF is converted into a hydrogenated oil product through the hydro-upgrading process HP, and the hydro-upgrading process HP includes the hydrofinishing process HT of the hydrocarbon oil HPF, and also includes the separation of the hydrofinishing process HT Hydrocracking process HC of hydrorefined wax oil HTVGO obtained mainly from hydrocarbon components with conventional boiling point higher than 350°C obtained by hydrogenation HTP.

[0125] This example forms a combination process of medium and low temperature coal tar deep drawing and vaporized oil hydrogenation upgrading process.

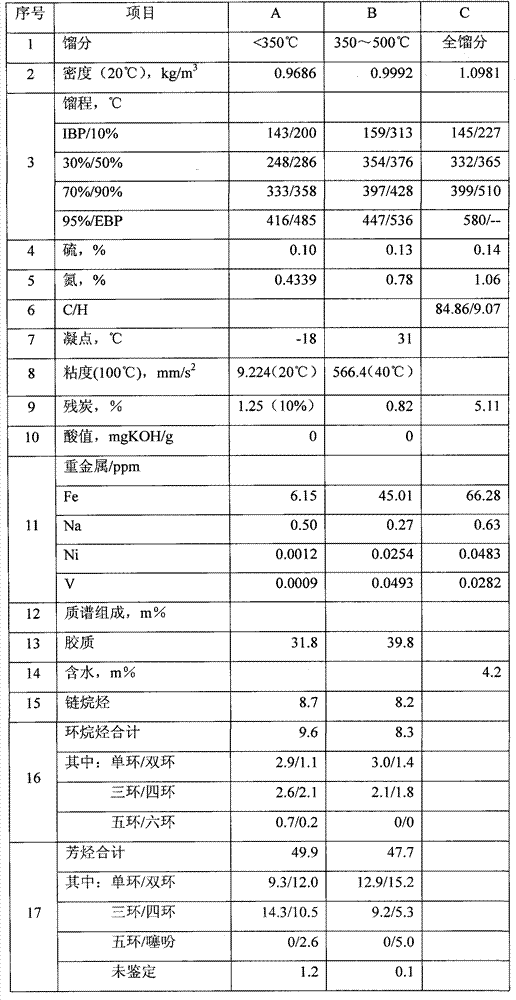

[0126] Table 1 Analysis data of coal tar properties

[0127]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com