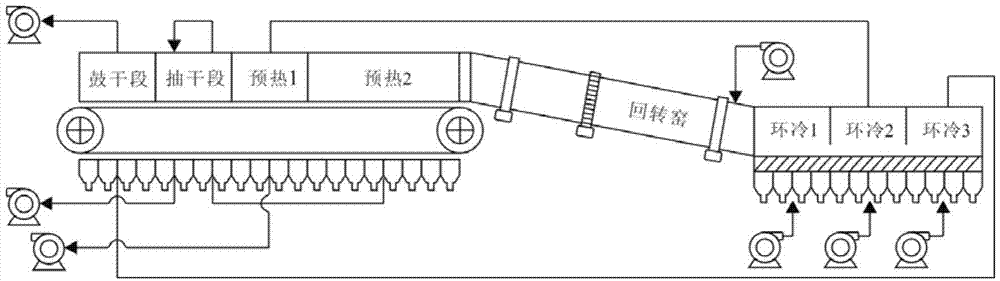

Optimizing method for pelletizing production integrating triune chain-and-grid conveyer, rotary kiln and circular cooler

An optimization method, a three-in-one technology, applied in the field of iron and steel metallurgy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The main equipment parameters of a grate-rotary kiln-circular cooler process in China are shown in Table 1. Table 2 shows the detected values of the selected state parameters for a period of time. According to the calculation of the stability evaluation standard formula, the selected state parameters are all stable, that is, the working condition at 22:00 reaches a steady state. At this time, the internal production process can be revealed through the three-in-one mathematical model of heat and mass transfer, and the on-site detection values of the input values of the mathematical model at 22:00 are shown in Table 3.

[0049] Table 1 The main equipment parameters of a grate-rotary kiln-circular cooler process

[0050]

[0051] Table 2 The detection value and steady state judgment result of the state parameters for a period of time

[0052]

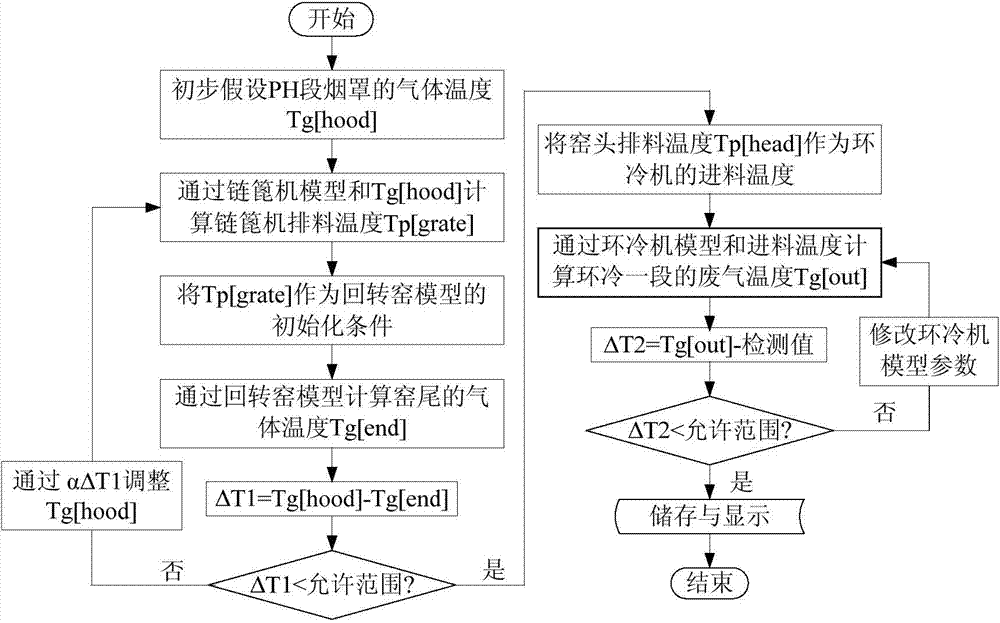

[0053] According to literature [1-5] and figure 2 The coupling algorithm shown, the calculation results of the math...

Embodiment 2

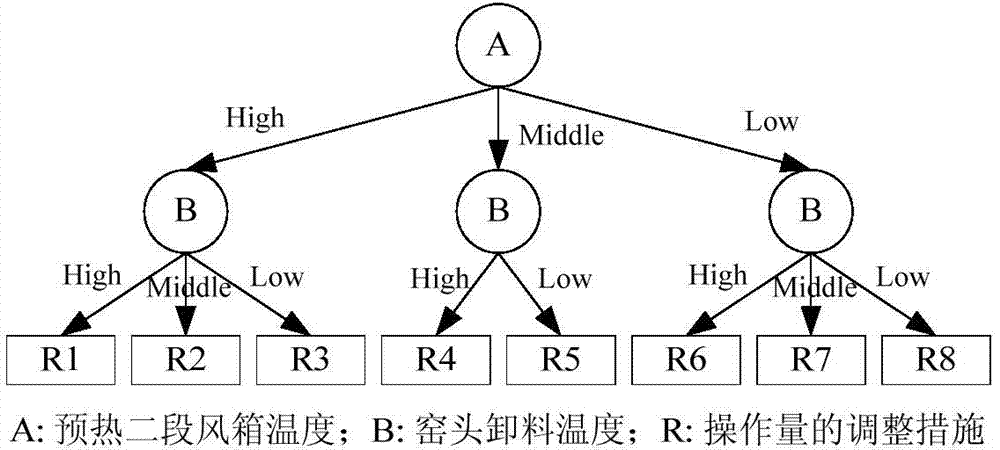

[0057] Table 4 shows the detection values of the state parameters in another time period. According to the calculation of the stability evaluation standard formula, some state parameters are not in a stable state, and the production is in a fluctuating state at 09:44. At this time, the temperature of the preheating second-stage air box is 419°C (low), the discharge temperature of the kiln head is 1126°C (normal), the discharge temperature of the third-stage annular cooling is 148°C (high), and the temperature of the hood of the third-stage annular cooling is 291°C (very high), the temperature of the second stage hood of the ring cooling is 908°C (very high), the system automatically matches the expert control rules, according to image 3 and Figure 4 At this time, the rules R2 and R9 will be activated, and the system will prompt "Keep the coal volume unchanged, reduce the PH burner flow rate, reduce the PH return hot air volume", "Increase the water pumping volume of the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com