Method for using stainless steel dust to produce chrome, nickel and iron alloy

A technology of inconel and stainless steel, which is applied in the field of comprehensive utilization of metallurgical waste, can solve the problems of short process equipment footprint, no use of electric furnace melting, and increased production costs, so as to improve the level of smelting, broaden the market, industrial application prospects, The effect of reducing smelting cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

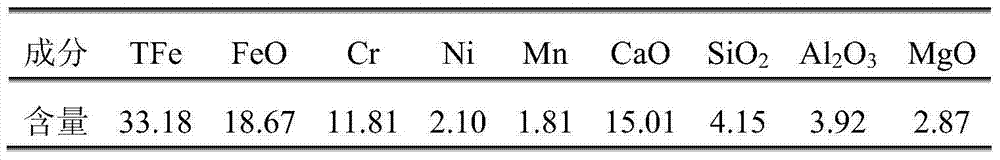

[0021] The TFe content contained in a certain stainless steel dust is 33.18%, the Cr content is 11.81%, and the Ni content is 2.10%. The main chemical composition is shown in Table 1.

[0022] The main chemical composition (wt%) of stainless steel dust in table 1 Example 1

[0023]

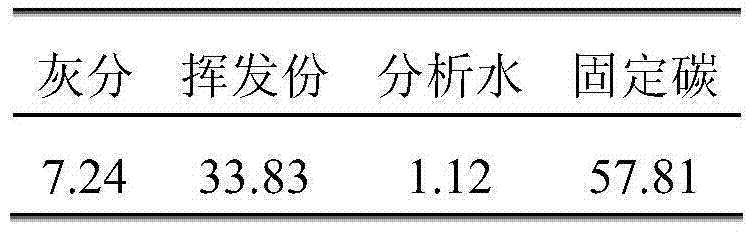

[0024] The fixed carbon content in a certain bituminous coal powder is 57.81%, the ash and volatile content are 7.24% and 34.01% respectively, and its colloidal layer index is not less than 8 to ensure that the hot briquette has sufficient compressive strength. The chemical composition is shown in Table 2.

[0025] Chemical composition (wt%) of table 2 bituminous coal powder

[0026]

[0027] After the stainless steel dust and coal powder are crushed and sieved, the stainless steel dust is 80% and the coal powder is 20% according to the mass percentage, mixed, heated and hot-pressed, and the hot-pressing temperature is controlled at 200°C and hot-pressed The pressure is 35 MPa, and the alkal...

example 2

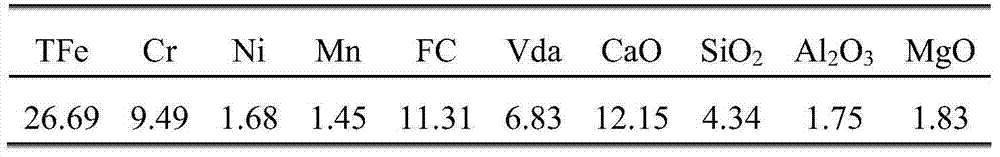

[0033] The stainless steel dust and coal powder that meet the particle size and composition requirements are mixed according to the ratio of 77.43% stainless steel dust and 22.57% coal powder in terms of mass percentage, mixed, heated and hot-pressed, and the hot-pressing temperature and hot-pressing pressure are controlled respectively 200 ℃ and 40MPa, the basicity of the carbon-containing stainless steel dust hot briquette obtained by final pressing is 2.68, and the main chemical composition of the carbon-containing stainless steel dust hot briquette is shown in Table 4.

[0034] The main chemical composition (wt%) of the carbon-containing stainless steel dust hot briquette in the example 2 of table 4

[0035]

[0036] The compressive strength of the obtained carbon-containing stainless steel dust hot briquetting block reaches 1210N / piece, and the drop strength reaches 5.1 times / piece.

[0037] Put the obtained hot briquette into the rotary hearth furnace. The hot briquet...

example 3

[0039] The stainless steel dust and coal powder that meet the particle size and composition requirements are mixed according to the ratio of 82.05% stainless steel dust and 17.95% coal powder in terms of mass percentage, and mixed, heated and hot-pressed, and the hot-pressing temperature and hot-pressing pressure are controlled respectively The basicity of the carbon-containing stainless steel dust hot briquette obtained by final pressing is 2.87, and the main chemical composition of the carbon-containing stainless steel dust hot briquette is shown in Table 5.

[0040] The main chemical composition (wt%) of the carbon-containing stainless steel dust hot briquette in the example 3 of table 5

[0041]

[0042] The compressive strength of the obtained carbon-containing stainless steel dust hot briquetting block reaches 1070N / piece, and the drop strength reaches 4.3 times / piece.

[0043] Put the obtained hot briquette into the rotary hearth furnace. The hot briquette is preheat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com