Intelligent and efficient purification method and device for turbocharged diesel engine

A technology of turbocharging and purification devices, which is applied to the electronic control of muffler devices, exhaust devices, exhaust treatment devices, etc. It can solve the problems of corroding cylinders, reducing engine power performance, reducing cylinder air intake, etc., and achieves high efficiency. Effect of purification reduction and power increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

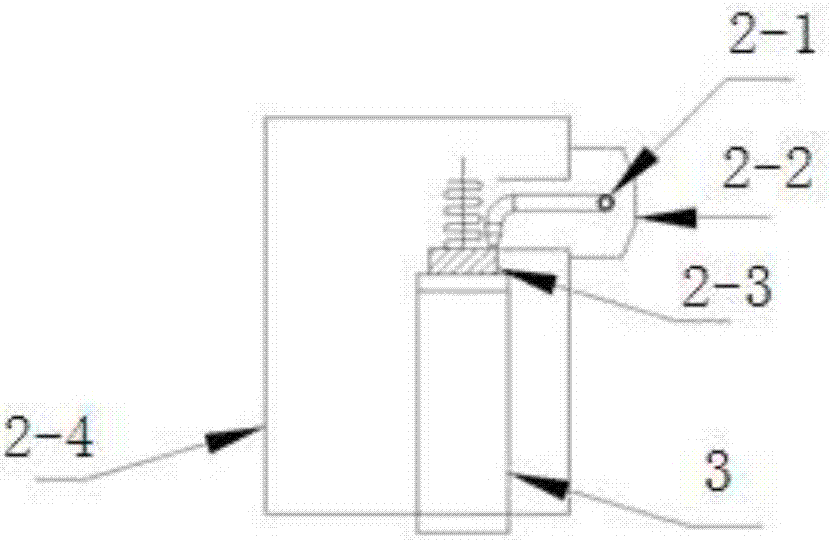

[0017] The intelligent and high-efficiency purification method of the turbocharged diesel engine is to directly use the superheated steam pipe to feed superheated steam into each cylinder of the diesel engine, so that the steam and air can enter the cylinder independently. The intelligent and efficient purification method for turbocharged diesel engines is to heat the water source through heat exchange on the outer wall of the engine exhaust pipe, and the heated hot water is injected into the superheated evaporator located at the outlet of the engine exhaust manifold to convert it into superheated water. The steam is passed into the engine cylinders.

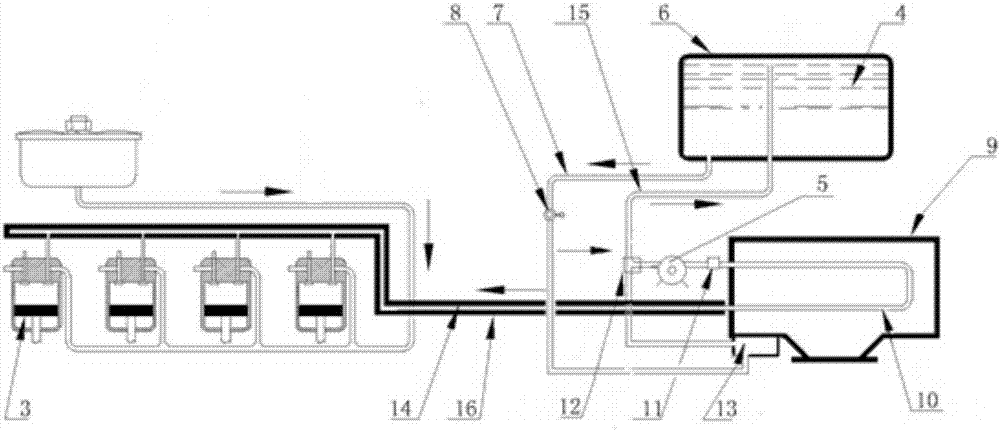

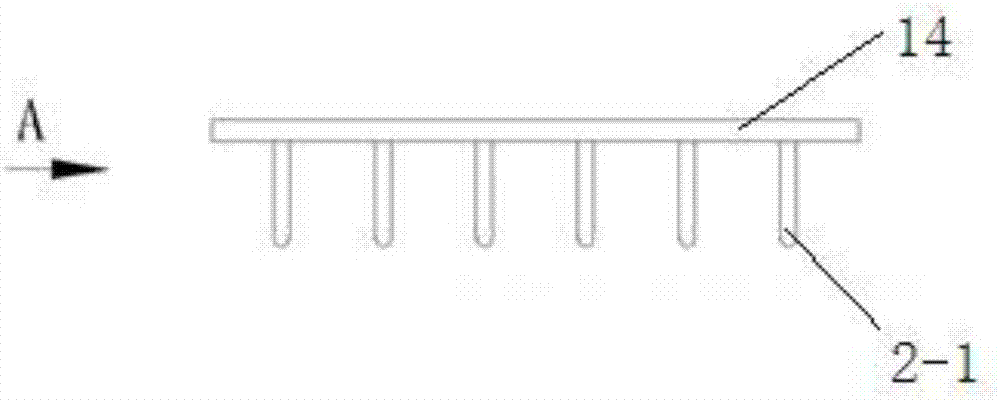

[0018] Realize the turbocharged diesel engine intelligent high-efficiency purification device system of described method such as figure 1 As shown, it includes a water tank 4, and the cold water pipe 7 of the water tank 4 outlet is equipped with a water inlet valve 8 and is connected with the water inlet of the heat exchanger wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com