Method for testing water content of crude oil

A technology of water content and crude oil, applied in the direction of material inspection products, etc., can solve the problems of low oil-water density, poor centrifugal separation effect, and low accuracy of crude oil water content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

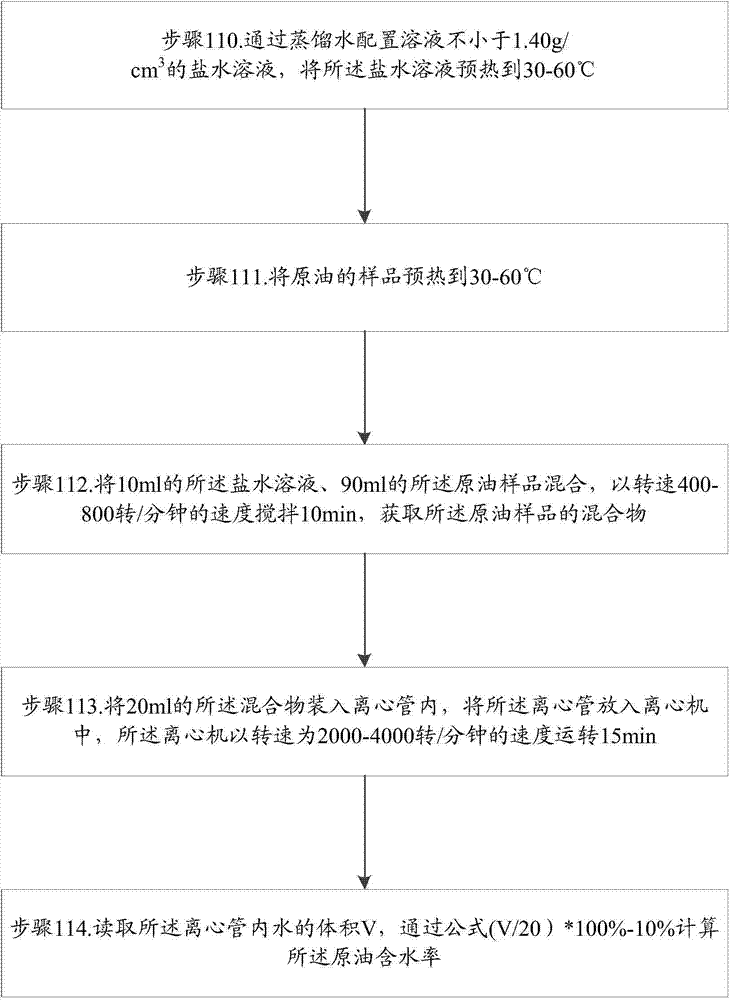

[0028] This embodiment provides a method for measuring the water content of crude oil, such as figure 1 As shown, the method mainly includes the following steps:

[0029] Step 110, configure the solution with distilled water not less than 1.40g / cm 3 brine solution, and preheat the brine solution to 30-60°C.

[0030] In this step, the brine solution can be configured through the calcium chloride, sodium formate, potassium formate, and cesium formate; the solubility of the calcium chloride, sodium formate, potassium formate, and cesium formate is not less than 0.4; in the brine solution, at least Including one of the calcium chloride, the sodium formate, the potassium formate, and the cesium formate.

[0031] Step 111, preheating the sample of crude oil to 30-60°C.

[0032] Step 112, mixing 10ml of the brine solution and 90ml of the crude oil sample, and stirring at a speed of 400-800 rpm for 10 minutes to obtain a mixture of the crude oil sample.

[0033] Step 113, put 20ml...

Embodiment 2

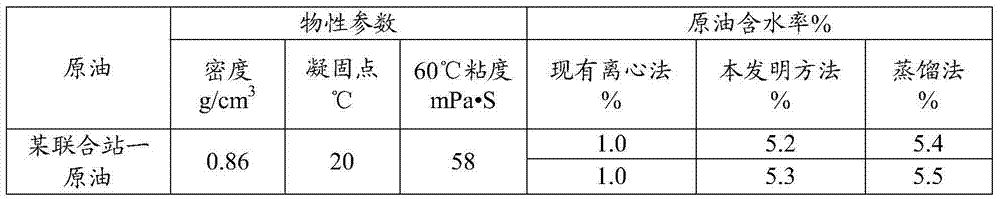

[0045] In practical application, in order to compare the measurement results of the water content of crude oil, the centrifugation method (for the specific method, refer to GB / T 6533 for the determination of water and sediment in crude oil), the distillation method (for the specific method, see GB260 for the determination of moisture content in petroleum products), and The method provided by the invention measures the moisture content of a crude oil in a combined station, and the experimental results are shown in Table 1. The operation steps of this embodiment include:

[0046](1) Prepare 75% potassium formate solution with distilled water and heat it to 40°C for later use.

[0047] (2) Measure 90mL of the oil sample preheated to 40°C, mix it with 10mL of the brine solution in step (1), stir for 10min, and the stirring speed is 400 rpm;

[0048] (3) Take two 20mL mixed oil samples prepared in step (2) and pour them into the first centrifuge tube and the second centrifuge tube...

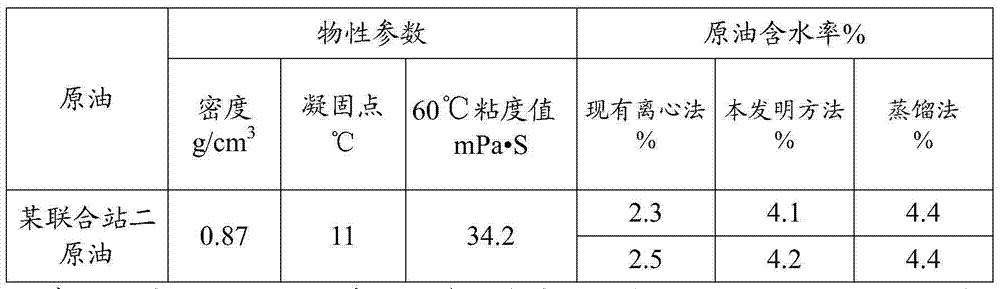

Embodiment 3

[0054] Crude oil exported from a joint station is heavy oil with a high freezing point and contains colloids and asphaltenes. In order to compare the measurement results of the water content of crude oil, the present embodiment adopts the centrifugation method (see GB / T 6533 for specific methods), the distillation method (see GB 260 for specific methods), and the method provided by the present invention to measure the water content of crude oil in a joint station two The experimental results are shown in Table 2. in,

[0055] The operation steps of this embodiment include:

[0056] (1) prepare 46% calcium chloride solution with distilled water for subsequent use, and be heated to 50 ℃ for subsequent use;

[0057] (2) Measure 90 mL of the oil sample preheated to 50°C, mix it with 10 mL of the saline solution in step (1), stir for 10 min, and the stirring speed is 600 rpm;

[0058] (3) Take two 20mL mixed sample oils configured in step (2) respectively, pour them into the fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com