Laser device for outputting flattened beams

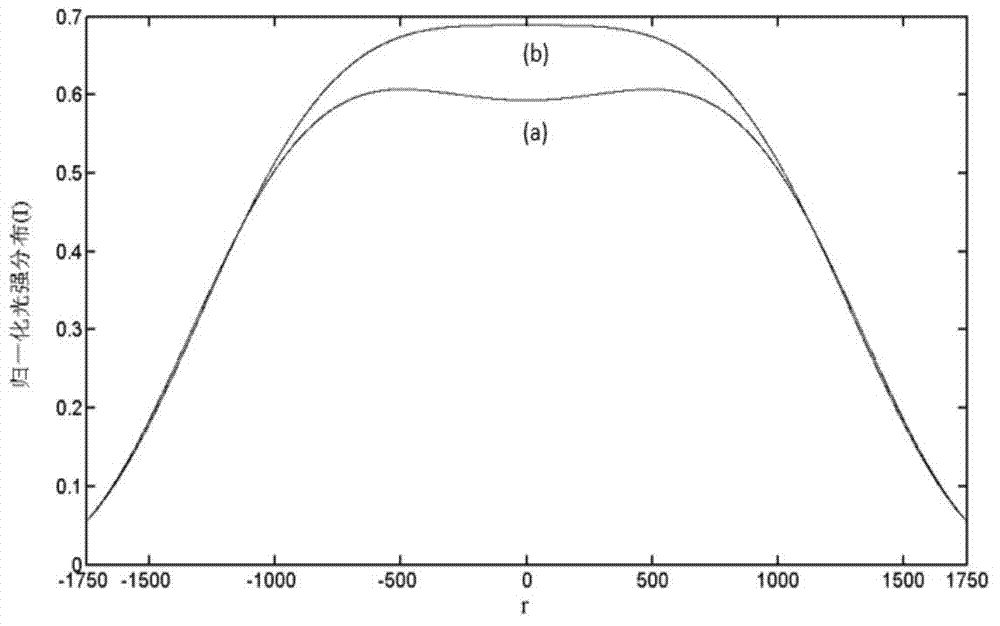

A flat-top beam and laser technology, applied in the laser field, can solve the problems of large loss and large loss of the shaping system, and achieve the effects of low loss, high filling factor and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited thereby.

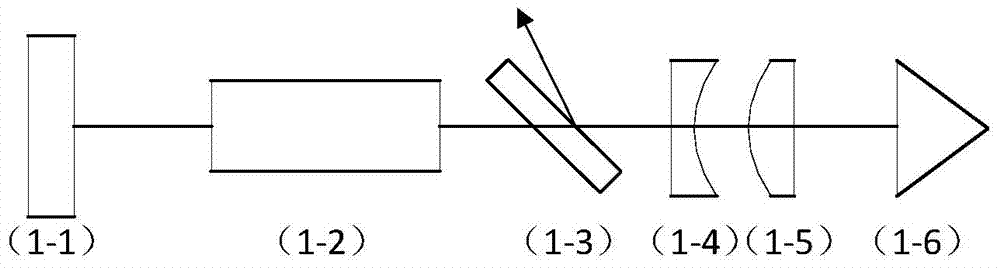

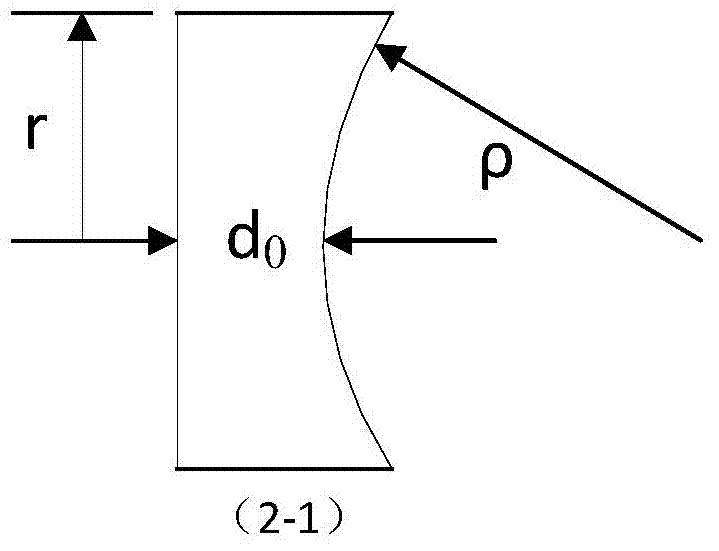

[0016] Such as figure 1 As shown, the laser output flat-hat beam of the present invention includes a reflective cavity mirror 1-1, a gain medium 1-2, a polarizer 1-3, a phase adjustment mirror 1-4, and a compensation lens 1 placed in sequence on the same optical axis. -5 and Porro Prisms 1-6. The reflective cavity mirror 1-1, gain medium 1-2, polarizer 1-3, phase adjustment mirror 1-4, compensation lens 1-5 and Porro prism 1-6 constitute a laser resonant cavity. The angle between the polarizer 1-3 and the optical axis is Brewster's angle, and the phase adjustment mirror 1-4 is a plano-convex lens or a plano-concave lens made of birefringent material. The compensation lens 1-5 is a plano-concave lens or a plano-convex lens, which adopts an isotropic medium or a cubic cryst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com