Graphite heat exchanger efficient washing method for silicon steel pickling line

A technology of graphite heat exchanger and silicon steel acid, which is applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of heavy environmental burden, damage to equipment, and inability to achieve cleaning effects, so as to avoid Environmental pollution and short cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

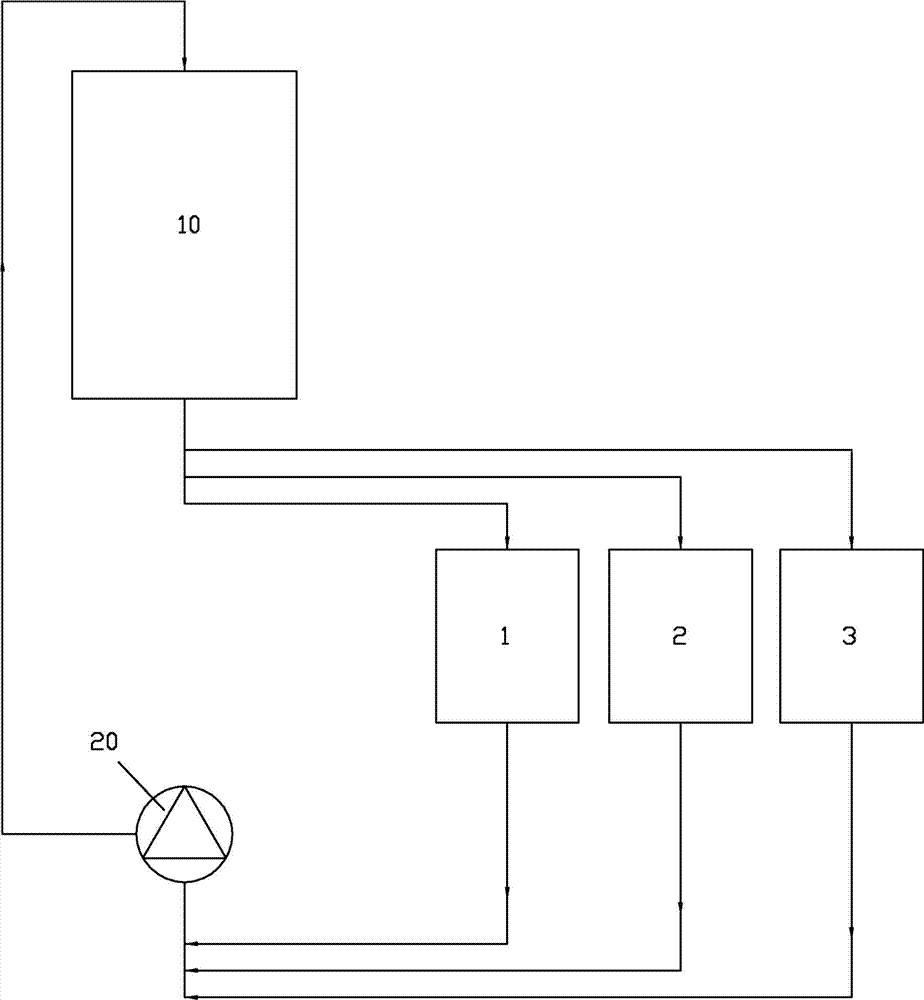

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0032] see figure 1 , the cleaning method of silicon steel pickling line graphite heat exchanger of the present invention, comprises the steps:

[0033] 1) Prepare 0.3wt% low-concentration hydrofluoric acid, store it in airtight storage at room temperature, and put it in 1# cleaning solution tank 1 for later use; prepare 1 wt% ammonia water, store it in airtight storage at room temperature, and put it in 2# cleaning solution tank 2 for use ; Prepare 15wt% sodium hydroxide solution, heat up to 75°C; add 0.5wt% ethylenediaminetetraacetic acid (EDTA) to the solution, and put it in 3# cleaning solution tank 3 for use;

[0034] 2) Disconnect the acid inlet and acid outlet pipes of the graphite heat exchanger 10, connect the inlet and outlet pipes of the graphite heat exchanger 10 and the 1# cleaning liquid tank 1 with polytetrafluoroethylene connecting hose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com