Preparation method of mesoporous manganic manganous oxide

A manganese tetroxide and mesoporous technology, applied in manganese oxide/manganese hydroxide and other directions, can solve the problems of difficult secondary treatment, waste generation, small specific surface area, etc., and achieve low cost, convenient operation and high catalytic oxidation. active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

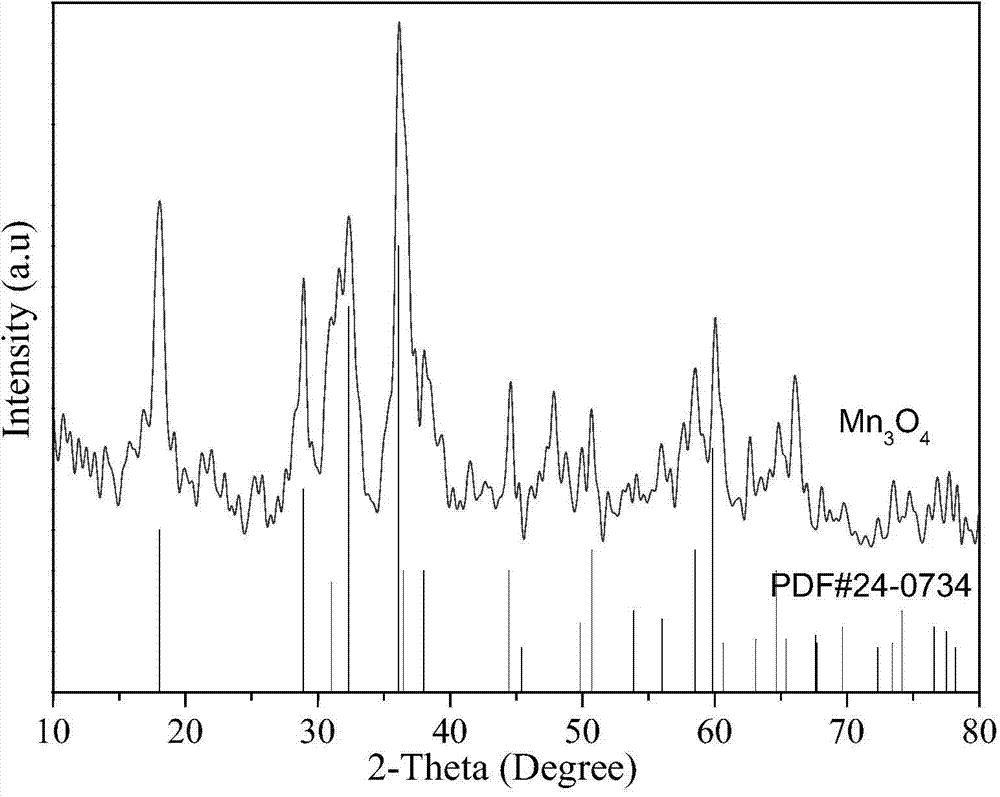

[0015] At room temperature, weigh 6mmol of CTAB and dissolve it in 200ml of distilled water, stir vigorously until completely dispersed; add 3.6ml of 50wt% Mn(NO 3 ) 2 Solution, continue to stir for 30 minutes, use 0.2mol / L NaOH solution to adjust pH = 9 to obtain a suspension, age at 90°C for 3 hours, wash with hot water, filter with suction, dry at 90°C for 6 hours, and bake at 400°C for 4 hours. Mesoporous trimanganese tetraoxide was prepared at 2°C / min, and the XRD pattern of the prepared mesoporous trimanganese tetraoxide was consistent with Mn 3 o 4 The standard diffraction pattern of figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com