Etching solution composition for copper and molybdenum containing film

A technology of composition and etching solution, which is applied in the direction of surface etching composition, photographic plate-making process of patterned surface, instruments, etc., can solve the problems of lower production efficiency, lengthening, poor wiring sections, etc., and achieve stable etching engineering , Improve the effect of etching cone angle

Active Publication Date: 2019-04-09

ENF TECH

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] If the thickness of the copper metal becomes thicker, the time of the etching process will be longer, which will reduce the production efficiency. If the etching speed is increased, the wiring section will be defective and problems will also occur.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1 to 6 and comparative example 1 to 3

[0079] The contents of the components listed in Table 1 below were mixed to prepare the compositions of Examples 1 to 6 and Comparative Examples 1 to 3 of the present invention.

[0080] 【Table 1】

[0081]

[0082] In the above table 1, ATZ: 5-aminotetrazole (5-aminotetrazole), IDA: iminodiacetic acid (iminodiacetic acid), and PHS: sodium bisulfate (Potassium hydrogen sulfate e), the content unit of each component is weight share.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Login to View More

Abstract

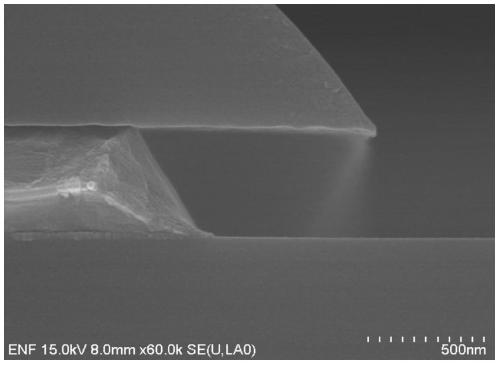

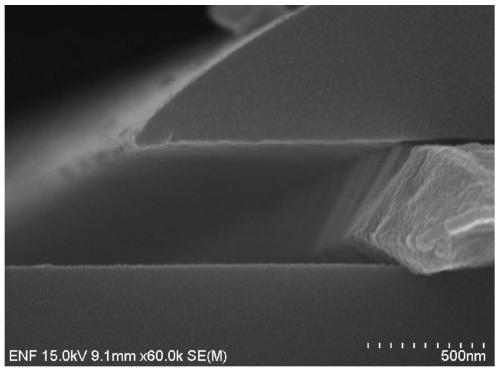

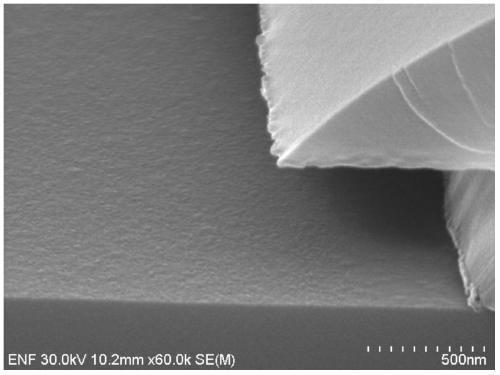

The invention relates to an etching liquid composition which is used for controlling lateral erosion of a molybdenum film or a molybdenum alloy film to realize stable etching processes when a copper-and-molybdenum-containing film is etched. The etching liquid composition can improve etching characteristics such as an etching taper angle, etching deviation, etching straightness and the like. The etching liquid composition comprises 10 to 30 weight% of a hydrogen peroxide, 0.1 to 5 weight% of an etching inhibitor, 0.1 to 5 weight% of a chelating agent, 0.1 to 5 weight% of an etching additive, 0.01 to 2 weight% of fluoride and 0.01 to 2 weight% of lateral erosion inhibitor; the total weight is enabled to be 100 weight% of water.

Description

technical field [0001] The present invention relates to an etchant composition of a copper-molybdenum film or a copper-molybdenum-containing film (hereinafter referred to as "copper / molybdenum-containing film"), especially an etchant combination of copper and molybdenum-containing films for TFT-LCD display electrodes things. Background technique [0002] Microcircuits such as semiconductor devices, TFT-LCDs, and OLEDs are coated evenly on conductive metal films such as aluminum, aluminum alloys, copper, and copper alloys or insulating films such as silicon dioxide films and silicon nitride films formed on substrates. The photoresist is then imaged after light irradiation through the patterned film to make the required pattern photoresist image, and the pattern is displayed on the metal film or insulating film under the photoresist by dry etching or wet etching Finally, a series of photolithography processes such as stripping and removing unnecessary photoresist are complete...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C23F1/14C23F1/18C23F1/26

CPCC09K13/04C23F1/14C23F11/149C23F11/165G03F7/00

Inventor 李恩庆殷熙天金世训申孝燮

Owner ENF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com