Etchant composition for silver layer and method for forming metal pattern and method for manufacturing display substrate using same

A composition and etchant technology, applied in the directions of surface etching compositions, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc., can solve problems such as no etching characteristics etchant composition, etc., to improve etching characteristics, increase Wetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 6 and comparative example 1 to 6

[0049] Examples 1 to 6 and Comparative Examples 1 to 6: Preparation of etchant compositions

[0050] 150 kg of each etchant composition was prepared using the components in the amounts (unit: wt %) shown in Table 1 below.

[0051] [Table 1]

[0052]

[0053]

[0054] *MTZ: 5-Methyltetrazole

[0055] Each etchant composition was placed in ETCHER (TFT) (manufactured by K.C. Tech) as an etching device, and then heated to a temperature of 40°C. When the temperature reaches 40±0.1° C., an etching process is performed. Etching as overetch increases the total etch time by 50% compared to endpoint detection (EPD).

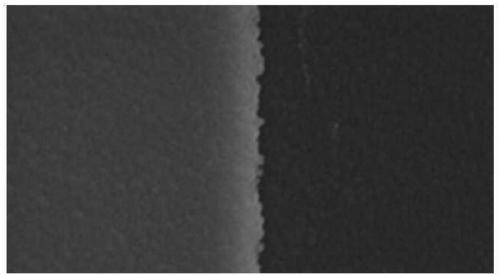

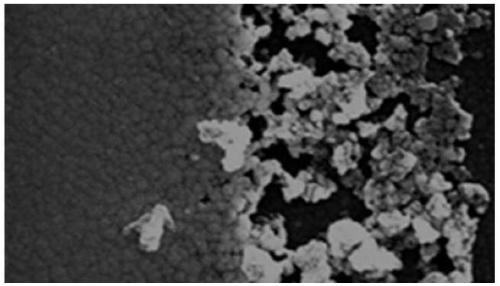

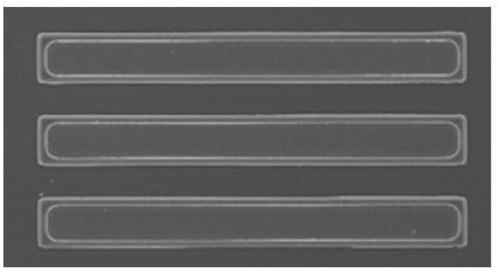

[0056] The substrate was placed in the etching equipment, etched by spraying, taken out from the etching equipment, rinsed with DI water and dried using a hot air dryer, and then the photoresist (PR) was removed using a PR stripper. After cleaning and drying, a scanning electron microscope (SEM, model name: S-4700, manufactured by HITACHI) was used to evaluate si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com