Vertical na131i retort production device

A production device and a vertical technology, applied in the field of vertical Na131I dry distillation production devices, can solve the problems of radioactive pollution work efficiency in the workplace, low utilization rate of raw materials, and many radioactive wastes, etc. Low pollution risk and the effect of improving single production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

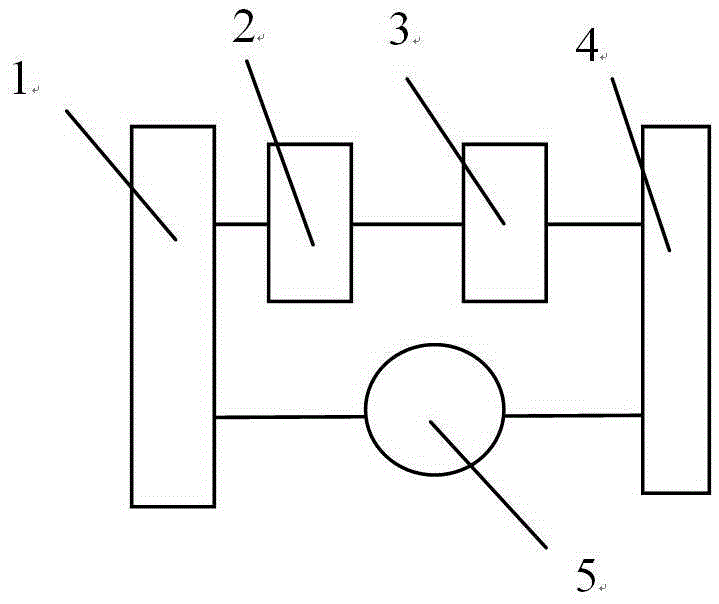

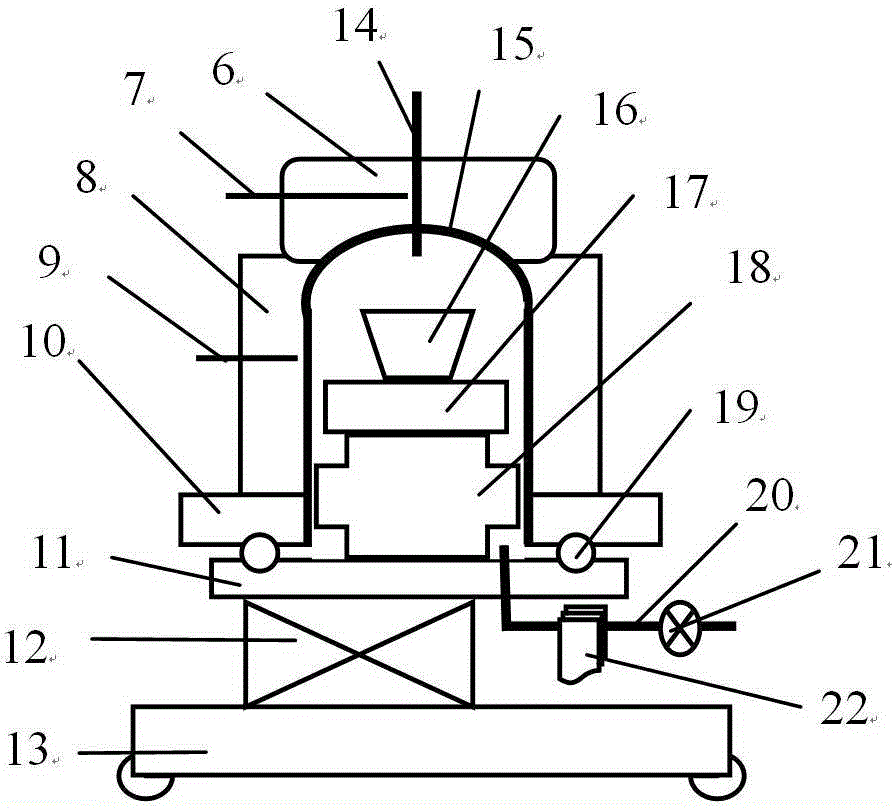

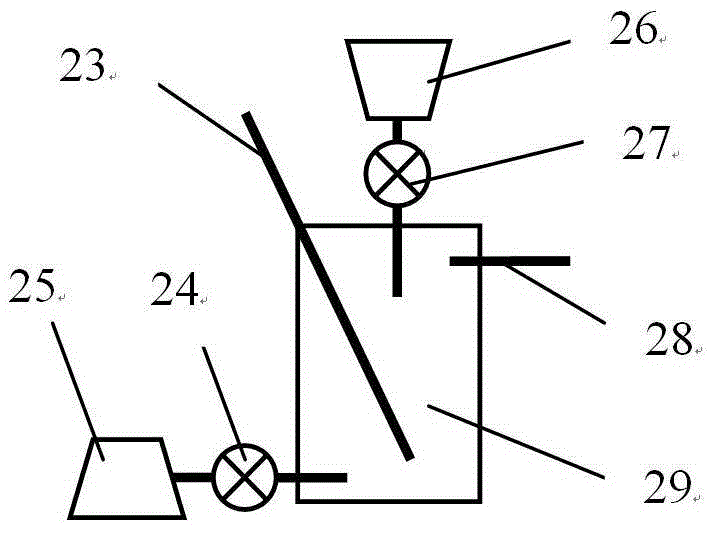

[0020] figure 1 is the upright Na of the present invention 131 The structural block diagram of 1 retort production plant, figure 2 is a structural schematic diagram of the dry distillation device in the present invention, image 3 It is a structural schematic diagram of the absorption tower in the present invention. exist Figure 1 ~ Figure 3 In the vertical Na of the present invention 131 1 carbonization production device, comprises carbonization device 1, absorption tower 2, purifier 3, vacuum pump 4, controller 5, and its connection relation is, described carbonization device 1 and absorption tower 2 are fixedly arranged, and carbonization device 1 is also connected with absorption tower 2. The purifier 3 and the vacuum pump 4 are connected sequentially through pipelines, and the dry distillation device 1 and the vacuum pump 4 are electrically connected to the controller 5 respectively. like figure 1 shown.

[0021] The dry distillation device 1 includes a heater I6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com