Method for preparing calcium carbide

A calcium carbide and lime technology, applied in the field of calcium carbide preparation, can solve the problems of high energy consumption and unrealized industrialization of calcium carbide process, and achieve the effects of saving energy consumption, saving smelting time, and reducing smelting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

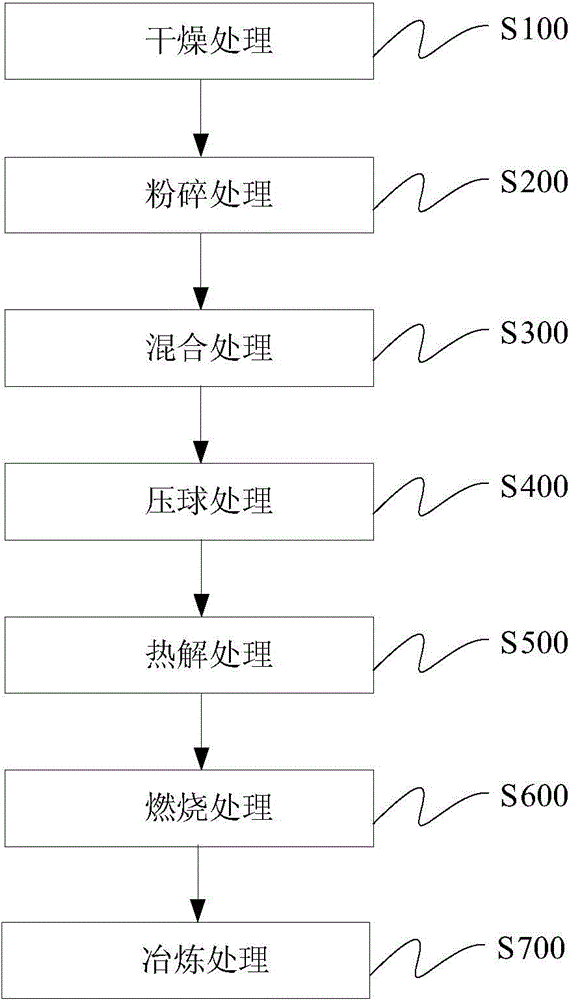

[0020] The method for preparing calcium carbide in the above-mentioned embodiments of the present invention combines the oxythermal method and the closed electric furnace method. By mixing excessive raw coal powder and lime powder in advance, performing pyrolysis and combustion, a high-temperature and close-contact semi-coke and lime powder are obtained. The pellet material is sent to the electric furnace for smelting treatment, which can significantly reduce the smelting temperature, save smelting time, and save energy consumption.

[0021] S100: drying treatment

[0022] According to a specific embodiment of the present invention, the raw coal is firstly dried to obtain dried raw coal. According to specific embodiments of the present invention, the type of raw coal is not particularly limited, for example, it may be cheap low-rank coal, thereby reducing costs. Moreover, the use of low-rank coal as the raw material for preparing calcium carbide can also expand the selection ...

Embodiment

[0046] raw material:

[0047] Quicklime is used as the calcium-based raw material, and the CaO content is greater than 92%;

[0048] The long-flame coal is used as the carbon-based raw material. The main properties of the long-flame coal are shown in Table 1.

[0049] Table 1

[0050] project

unit

value

Remark

whole water

%

13

Receive base

%

58

Volatile matter

%

36

Ash

%

6

[0051] Preparation:

[0052] First, the raw coal is dried with a chain plate dryer, the drying heat source is hot flue gas at 120-180°C, and the moisture content of the long-flame coal after drying is less than 0.8%.

[0053] After drying, the long-flame coal is pulverized by a mechanical mill, and the average particle size after pulverization is less than 10 microns.

[0054] The pulverized long-flame coal powder and lime powder are mixed in an intensive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com