A kind of lead-free potassium-barium glass ball and its production process

A lead-free potassium-barium and production process technology is applied in the field of glass materials to achieve the effects of reducing energy consumption, good covering ability and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

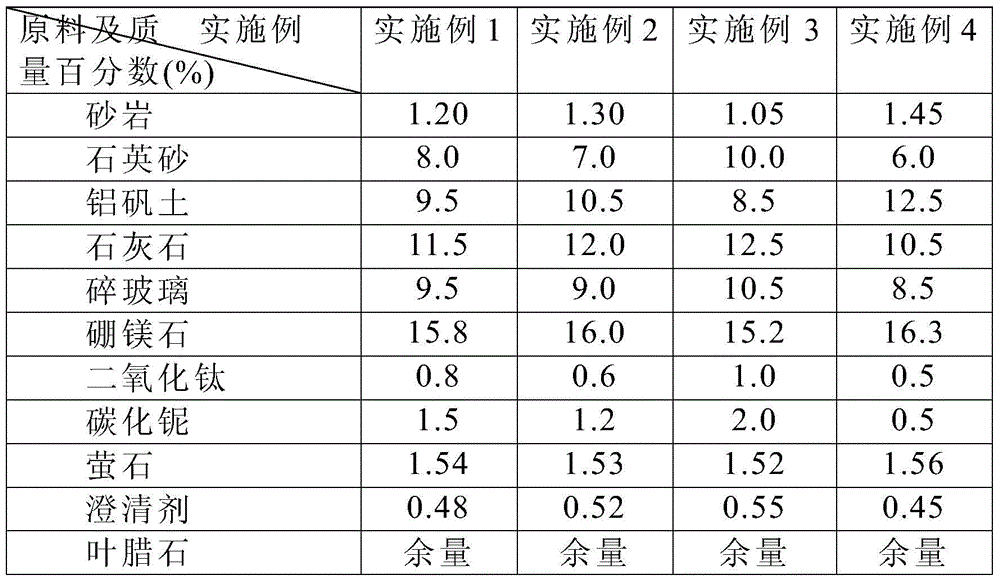

Embodiment 1

[0046] Batching: take the raw material of lead-free potassium-barium glass ball described in the embodiment 1 of table 1, put into the mixing machine except the raw material except cullet to make batching, wherein, the particle diameter of described quartz sand is 80mm, the limestone The particle size is 100mm, and the particle size of titanium dioxide is 100nm; the cullet is colorless cullet; the chemical composition and mass percentage of the clarifying agent are: CeO 2 : 6.8%, Sb 2 o 3 : 2.20%, Al 2 o 3 : 1.9%, Na 2 O: 0.3%, SiO 2 : 18.8%, and the balance is CaO; the boronite is calcined at 590°C for 12min; the particle size of the boronite is 60mm, and its chemical composition and mass percentage are: MgO: 15%, Fe 2 o 3 : 0.15%, K 2 O: 0.05%, the balance is B 2 o 3 The particle diameter of described pyrophyllite is 850mm, and its chemical composition and mass percentage are: Al 2 o 3 : 22.2%, CaO: 0.60%, MgO: 0.16%, Na 2 O+K 2 O: 0.48%, Fe 2 o 3 : 0.23%, th...

Embodiment 2

[0051] Batching: take by weighing the raw material of lead-free potassium-barium glass ball described in the embodiment 2 of table 1, put into the mixing machine except the raw material except cullet to make batching, wherein, the particle diameter of described quartz sand is 120mm, the limestone The particle size is 120mm, and the particle size of titanium dioxide is 120nm; the cullet is colorless cullet; the chemical composition and mass percentage of the clarifying agent are: CeO 2 : 7.2%, Sb 2 o 3 : 2.18%, Al 2 o 3 : 2.0%, Na 2 O: 0.2%, SiO 2 : 18.7%, and the balance is CaO; the boronite is calcined at 585°C for 14min; the particle size of the boronite is 50mm, and its chemical composition and mass percentage are: MgO: 14.5%, Fe 2 o 3 : 0.20%, K 2 O: 0.1%, the balance is B 2 o 3 The particle diameter of described pyrophyllite is 120mm, and its chemical composition and mass percentage are: Al 2 o 3 : 22.8%, CaO: 0.61%, MgO: 0.17%, Na 2 O+K 2 O: 0.50%, Fe 2 o ...

Embodiment 3

[0056] Batching: take the raw material of lead-free potassium-barium glass ball described in the embodiment 3 of table 1, put into the mixing machine except the raw material except cullet to make batching, wherein, the particle diameter of described quartz sand is 30mm, the limestone The particle size is 150mm, and the particle size of titanium dioxide is 50nm; the cullet is colorless cullet; the chemical composition and mass percentage of the clarifying agent are: CeO 2 : 6.5%, Sb 2 o 3 : 2.30%, Al 2 o 3 : 1.8%, Na 2 O: 0.5%, SiO 2 : 18.5%, and the balance is CaO; the boronite is calcined at 580°C for 15min; the particle size of the boronite is 30mm, and its chemical composition and mass percentage are: MgO: 14%, Fe 2 o 3 : 0.25%, K 2 O: 0.02%, the balance is B 2 o3 The particle diameter of described pyrophyllite is 80mm, and its chemical composition and mass percentage are: Al 2 o 3 : 21.5%, CaO: 0.62%, MgO: 0.15%, Na 2 O+K 2 O: 0.54%, Fe 2 o 3 : 0.22%, the ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com