Multi-effect ferment fertilizer prepared from agricultural wastes

An agricultural waste and multi-functional technology, applied in fertilizers made of biological waste, agriculture, fertilization equipment, etc., can solve problems such as difficult absorption and utilization of straw, pollution of livestock and poultry manure, pollution of farms and surrounding environments, and avoid Deterioration of soil properties, improvement of fertilizer supply capacity, and effects of avoiding nutrient loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

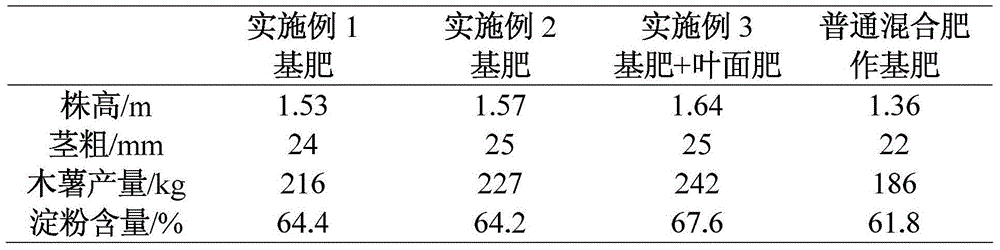

Embodiment 1

[0029] Using poultry manure, cassava stalks and waste molasses to make multifunctional enzyme fertilizer, the preparation process includes the following steps:

[0030] (1) Crush 30 parts of cassava stalks into small pieces of about 3 cm, add them into the fermentation tank together with 55 parts of poultry manure and 15 parts of waste molasses and mix well, add water until all raw materials are submerged.

[0031] (2) According to 150g / m 3 The amount of inoculated activated EM strains, after stirring, the fermentation tank was covered and fermented for 30 days.

[0032] Activation of EM strains: Take 1 part of EM strains, 8 parts of brown sugar, 0.1 parts of table salt, 0.5 parts of urea, and 10 parts of water, boil the water and add it to the red pond, keep boiling for 5 minutes, and add EM strains when it cools down to 40°C , salt, urea, and closed fermentation at room temperature for 3 days to obtain activated EM strains.

[0033] (3) 15 days before the application, the ...

Embodiment 2

[0037] Using poultry manure, cassava stalks and waste molasses to make multifunctional enzyme fertilizer, the preparation process includes the following steps:

[0038] (1) Crush 40 parts of cassava stalks into small pieces of about 3 cm, put them into the fermentation tank together with 45 parts of poultry manure and 15 parts of waste molasses and mix well, add water until all raw materials are submerged.

[0039] (2) According to 180g / m 3 The amount of inoculated activated EM strains, after stirring, the fermentation tank was covered and fermented for 45 days.

[0040]Activation of EM strains: Take 1 part of EM strains, 9 parts of brown sugar, 0.15 parts of table salt, 0.8 parts of urea, and 15 parts of water, boil the water and add the red pond, keep boiling for 7 minutes, and add EM strains when it cools to 45°C , salt, urea, and closed fermentation at room temperature for 4 days to obtain activated EM strains.

[0041] (3) 20 days before the application, the fermentatio...

Embodiment 3

[0045] Using poultry manure, cassava stalks and waste molasses to make multifunctional enzyme fertilizer, the preparation process includes the following steps:

[0046] (1) Crush 50 parts of cassava stalks into small pieces of about 3 cm, add them together with 40 parts of poultry manure and 10 parts of waste molasses into the fermentation tank and mix evenly, add water until all raw materials are submerged.

[0047] (2) According to 200g / m 3 The amount of inoculated activated EM strains, after stirring, the fermentation tank was covered and fermented for 60 days.

[0048] Activation of EM strains: Take 1 part of EM strains, 10 parts of brown sugar, 0.2 parts of table salt, 1 part of urea, and 20 parts of water, boil the water and add it to the red pond, keep boiling for 10 minutes, and add EM strains when it cools down to 50°C , salt, urea, and closed fermentation at room temperature for 5 days to obtain activated EM strains.

[0049] (3) 30 days before application, unseal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com