A kind of preparation method of pramlintide acetate

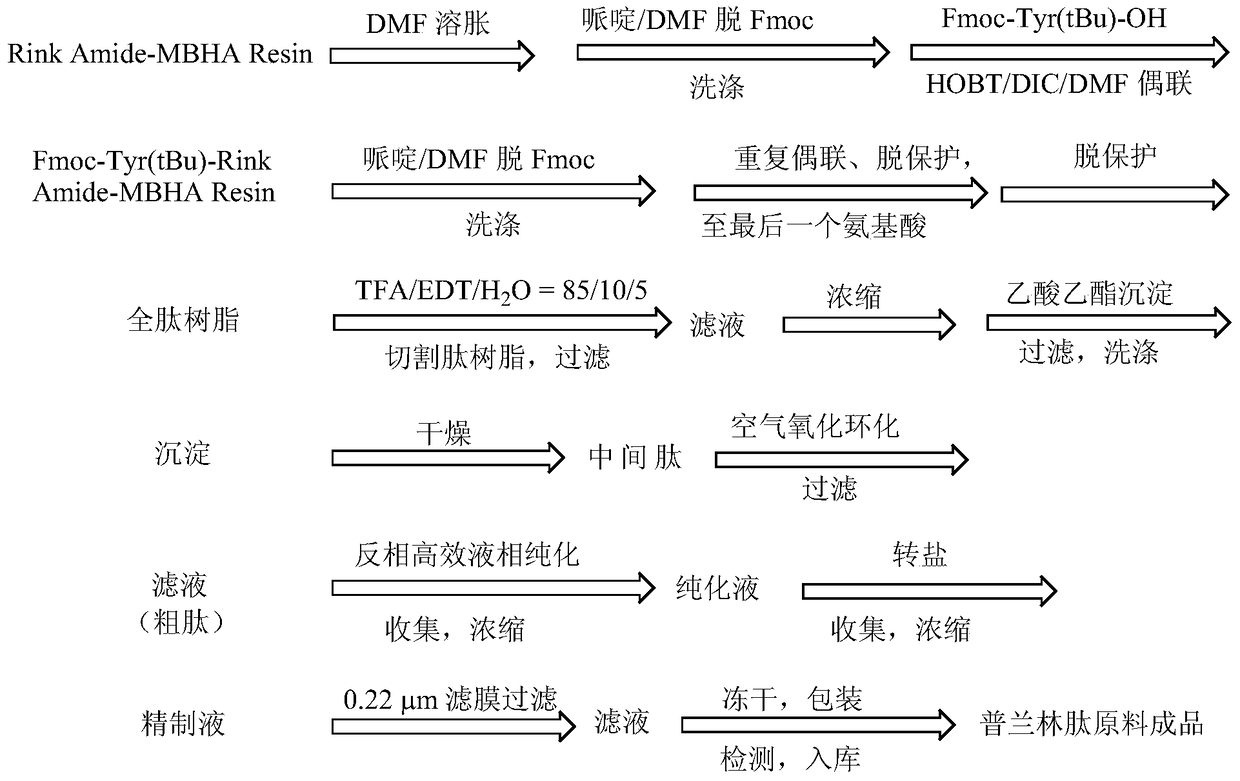

A technology of pramlintide acetate and crude peptides, which is applied in the preparation method of peptides, chemical instruments and methods, peptides, etc., can solve the problem that the purification process of pramlintide acetate is not mentioned in detail, the iodine oxidation method is not simple and practical, and the process is complicated and other problems, to achieve the effect of improving production efficiency and quality, convenient operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

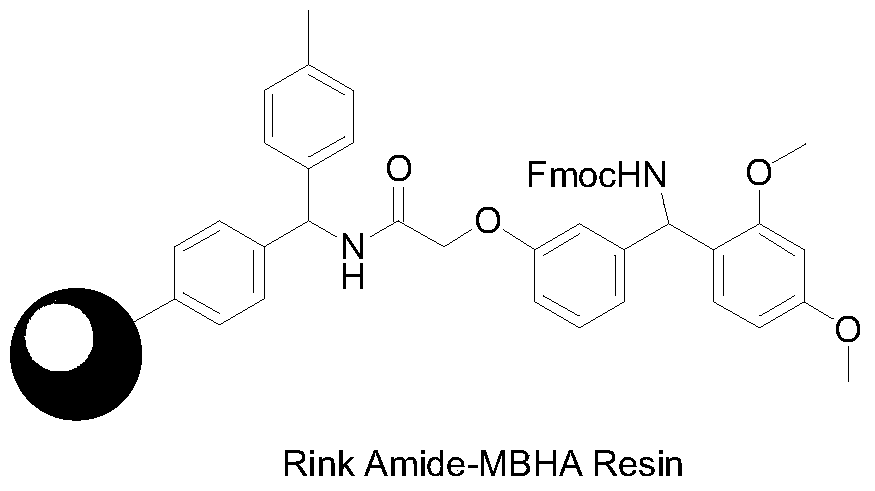

[0063] Embodiment 1: the preparation of Fmoc-Tyr (tBu)-Rink MBHA Resin amino resin

[0064] Add 40g (10mmol) of Rink Amide-MBHA Resin amino resin with a substitution degree of 0.25mmol / g to the glass reaction column, add 200mL DMF to it for swelling for 30min, and then add 200mL to the glass reaction column to configure a volume concentration of 20 % piperidine in DMF, and stirred for 30min, then the reaction solution was removed, and then DMF was added to the glass reaction column for washing, washing 6 times, each consumption 200mL; simultaneously weighed 50mmol of Fmoc-Tyr ( tBu)-OH and 50mmol of HOBT, these two substances were dissolved with 200mL of DMF, after the dissolution was complete, 50mmol of DIC was added to it to form a mixed solution, and after stirring again, the mixed solution was added to the glass reaction column, and stirred for 2 Hour. Thereafter, the liquid was extracted and washed with DMF for 6 times, each time with a dosage of 200 mL; namely, about 42...

Embodiment 2

[0065] Embodiment 2: the synthesis of whole peptide resin

[0066] To the Fmoc-Tyr(tBu)-Rink MBHA Resin amino resin generated in step 1), add 200mL of the DMF solution of piperidine with a volume concentration of 20% configured, stir and allow it to react for 30min, then remove the liquid and wash with DMF The product was used 10 times, each dosage was 200mL, the washing solution DMF was drained, and then 50mmol of Fmoc-Thr(tBu)-OH and 50mmol of HOBT were weighed, and these two substances were dissolved in 200mL of DMF. Add 50mmol of DIC to form a mixed solution, stir again, add the mixed solution into the glass reaction column, stir and react for 2 hours, then remove the liquid, wash the product 6 times with DMF, each time 200mL, and drain it. Obtain Fmoc-Thr(tBu)-Tyr(tBu)-Rink MBHA Resin amino resin, then add a deprotection reagent to sequentially couple and deprotect the remaining amino acids, and operate until the last amino acid is coupled to obtain a full peptide resin ...

Embodiment 3

[0067] Embodiment 3: the cleavage of whole peptide resin

[0068] Preparation of lysate:

[0069] Take a 2000mL round bottom flask, add 850mL of TFA, 100mL of EDT, 50mL of H 2 0, and stirred to obtain a lysate.

[0070] Cracking:

[0071] Add 100 g of peptide resin to the lysate, stir and react for 3 hours, then filter with a sand core funnel, wash the filtered resin with 400 mL of TFA, repeat the filtration and washing twice, combine the filtrate, and concentrate under reduced pressure to the volume of the filtrate. It is about 1 / 10 of the original volume, and then it is added to the pre-cooled ethyl acetate solvent whose volume is 10 times that of the concentrated solution, and a white solid is precipitated, and the white solid is filtered, and the filtered white solid is washed with ethyl acetate The ester was washed 4 times, each time with 400 mL of ethyl acetate, filtered to obtain a solid powder, dried in vacuum for 12 hours, taken out and weighed to obtain 23.5 g of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com