Method for preparing boron modified phenolic resin

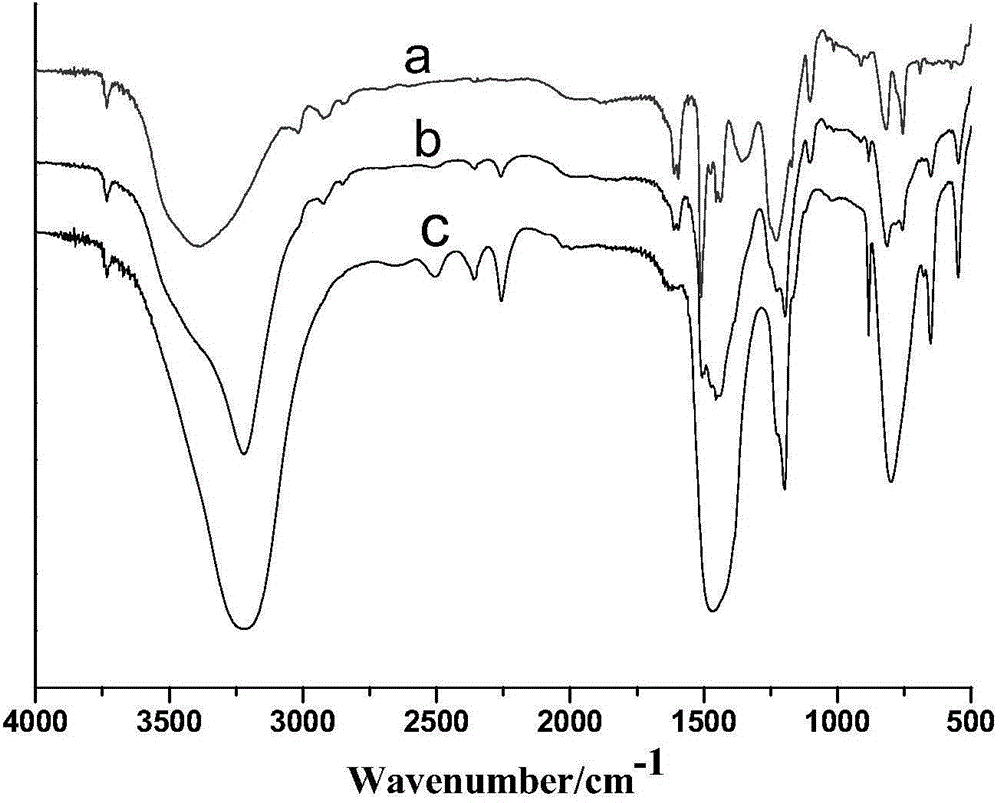

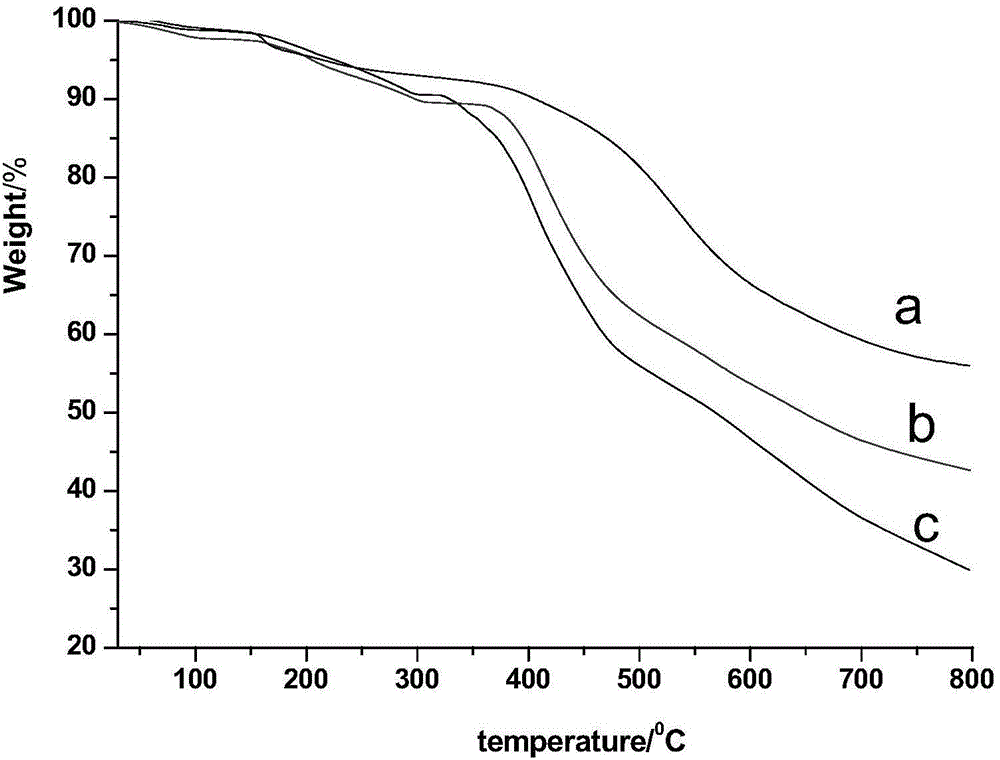

A phenolic resin, boron modification technology, applied in the field of polymer synthesis and modification, can solve the problems of easy curing and crosslinking, poor storage stability, limited boron content, etc., achieve excellent heat resistance, increase reactivity, and improve boron content. The effect of the content of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] Further, the preparation method of boron modified phenolic resin of the present invention, comprises the steps:

[0027] 1) Add the organoboron compound and aldehyde into the reaction kettle, stir evenly, adjust the pH of the reaction solution to 8-12 with alkali, raise the temperature to 80-120°C, and react for 1-6h;

[0028] 2) Add phenol to the reaction solution obtained in step 1), adjust the pH to 2-5 with an acid, react at a temperature of 70-100° C. for 1-5 hours, and adjust the pH of the solution to 1-2 with an acid;

[0029] 3) Take the aldehyde, adjust the pH to 1-2 with an acid, add it to the reaction solution obtained in step 2), and react for 1-8 hours at a temperature of 80-120° C. to obtain a boron-modified phenolic resin.

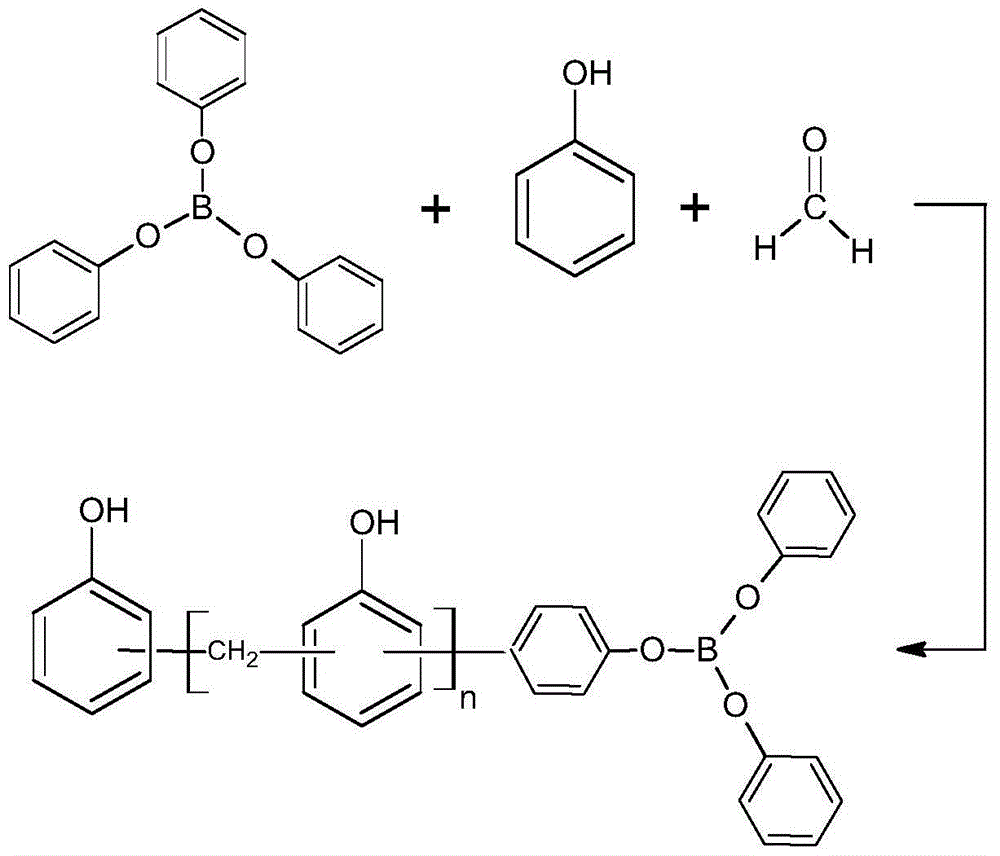

[0030] Taking triphenyl borate, formaldehyde and phenol as examples, the main reaction formula is as follows:

[0031]

[0032] Among them, R 1 , R 2 ...R 9 independently selected from H or CH 2 OH, and R 1 , R 2 ...R 9 At ...

Embodiment 1

[0050] 1) Add 15 parts of triphenyl borate and 17 parts of 37% formaldehyde solution into the reaction kettle, stir evenly, adjust the pH of the reaction solution to 8-10 with sodium hydroxide, heat up to 95°C, and react for 4 hours;

[0051] 2) Add 100 parts of phenol to the reaction mixture obtained in step 1), adjust the pH to 2-3 with oxalic acid, raise the temperature to 90° C., react for 3 hours, and adjust the pH of the solution to 1-2 with hydrochloric acid;

[0052] 3) Take 65 parts of 37% formaldehyde solution, adjust the pH to 1-2 with oxalic acid, add it to the reaction solution obtained in step 2), and react for 3 hours at a temperature of 100 ° C. After dehydration, branched with high boron content is obtained. Boron modified phenolic resin.

[0053] After testing, the obtained boron-modified phenolic resin has a molecular weight of 3553 and a boron content of 0.5%.

Embodiment 2

[0055] 1) Add 10 parts of L-norvalyl diphenyl borate and 18 parts of 37% formaldehyde solution into the reaction kettle, stir evenly, adjust the pH of the reaction solution to 8-10 with potassium hydroxide, and heat up to 100°C , reaction 4h;

[0056] 2) Add 100 parts of phenol to the reaction mixture obtained in step 1), adjust the pH to 2-3 with phosphonic acid, raise the temperature to 95° C., react for 3 hours, and adjust the pH of the solution to 1-2 with oxalic acid;

[0057] 3) Take 69 parts of 37% formaldehyde solution, adjust the pH to 1-2 with hydrochloric acid, add it to the reaction solution obtained in step 2), and react for 4 hours at a temperature of 100°C. After dehydration, a branched product with high boron content is obtained. Boron modified phenolic resin.

[0058] After testing, the weight-average molecular weight of the obtained boron-modified phenolic resin is 3764, and the content of boron connected to the resin by chemical bonds is 0.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com