CaMg<2>Al<16>O<27>:Mn <4+> red fluorescent powder and preparation technology thereof

A camg2al16-xo27, red phosphor technology, applied in the field of solid luminescent materials, can solve the problems of unstable physical and chemical properties of red phosphors, harsh preparation conditions, expensive raw materials, etc., and achieves low cost, simple preparation process, and cheap raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

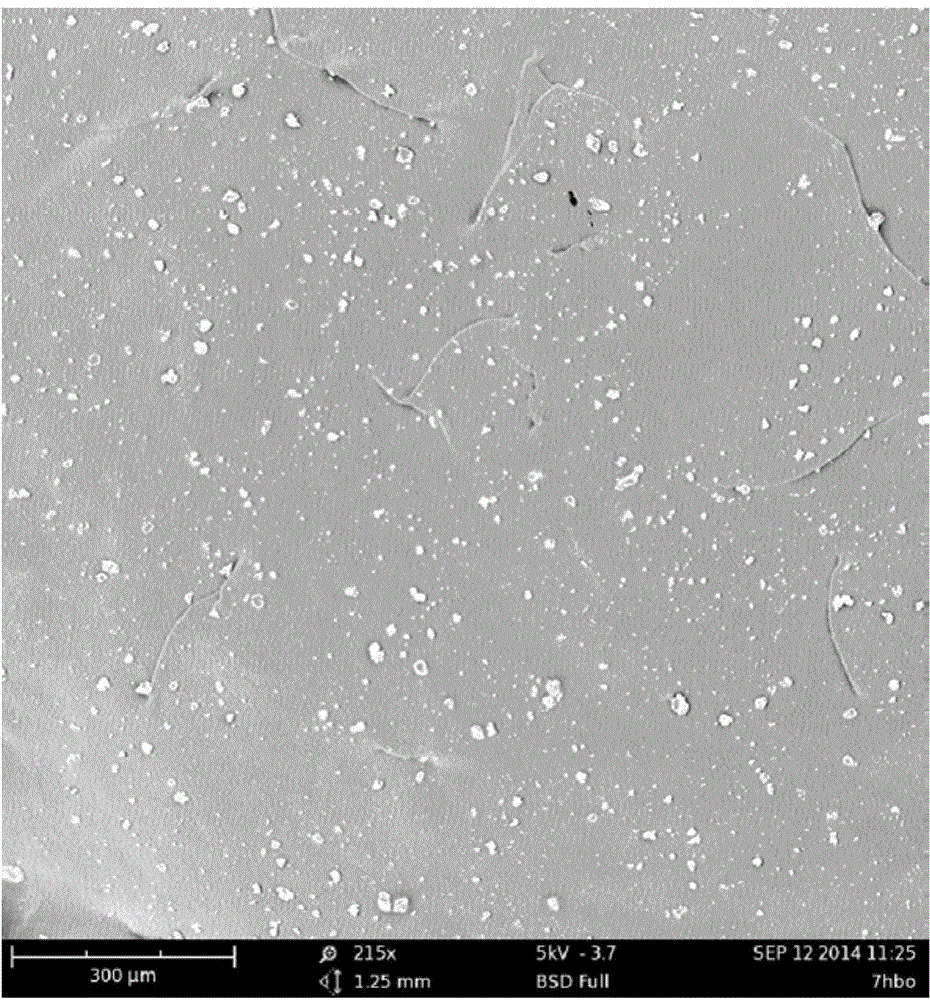

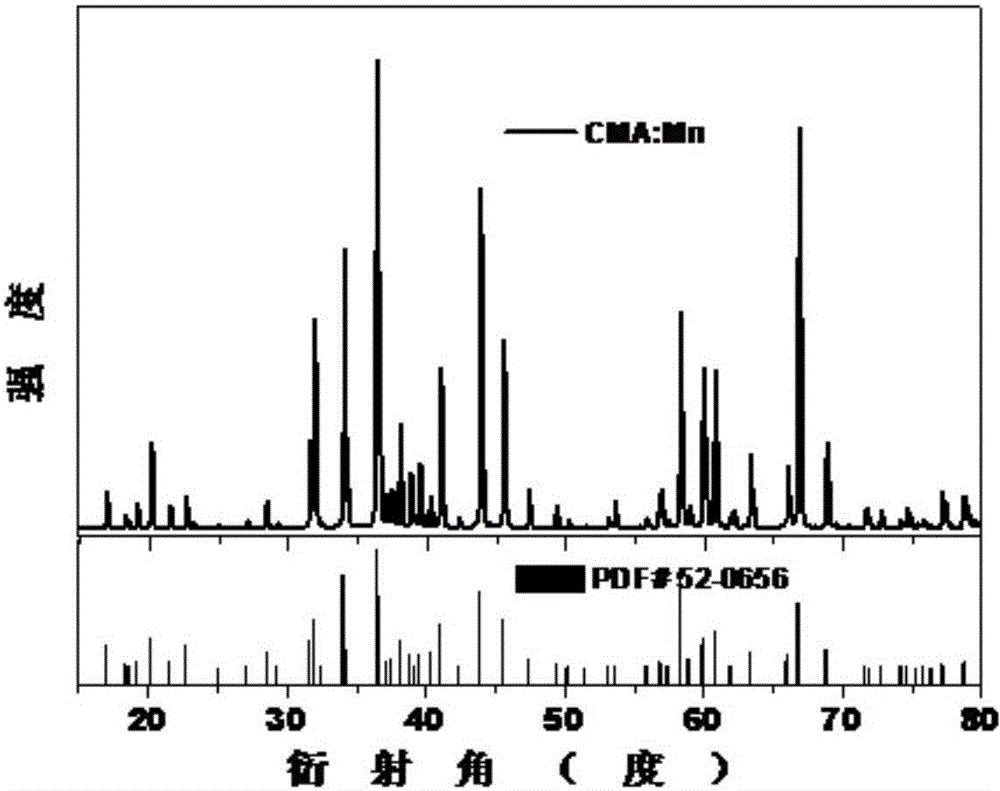

[0022] Example 1: Analytical pure CaCO 3 、Al 2 o 3 , MgO, and MnCO 3 Powder, as CaCO 3 :2MgO:7.96Al 2 o 3 :0.08MnCO 3 The ratio of (molar ratio) is accurately weighed and placed in an agate mortar, and an appropriate amount of ethanol is added to grind for 30 minutes to make it evenly mixed; then placed in a 60°C oven for about 3-5 minutes, after taking it out, put it in the grinder Continue to grind in the bowl for 15 minutes, then place it in a square crucible, heat it to 1550°C in a high-temperature program-controlled high-temperature box-type resistance furnace, keep it warm for 4 hours, and cool down with the furnace to obtain a sample. Grinding and sieving to obtain phosphor powder, the color of the phosphor powder observed is light pink. According to the scanning electron microscope observation, it can be seen that the prepared powder sample has a size of 20 microns, such as figure 1 Shown; X-ray diffraction analysis result, the fluorescent powder that obtains i...

example 2

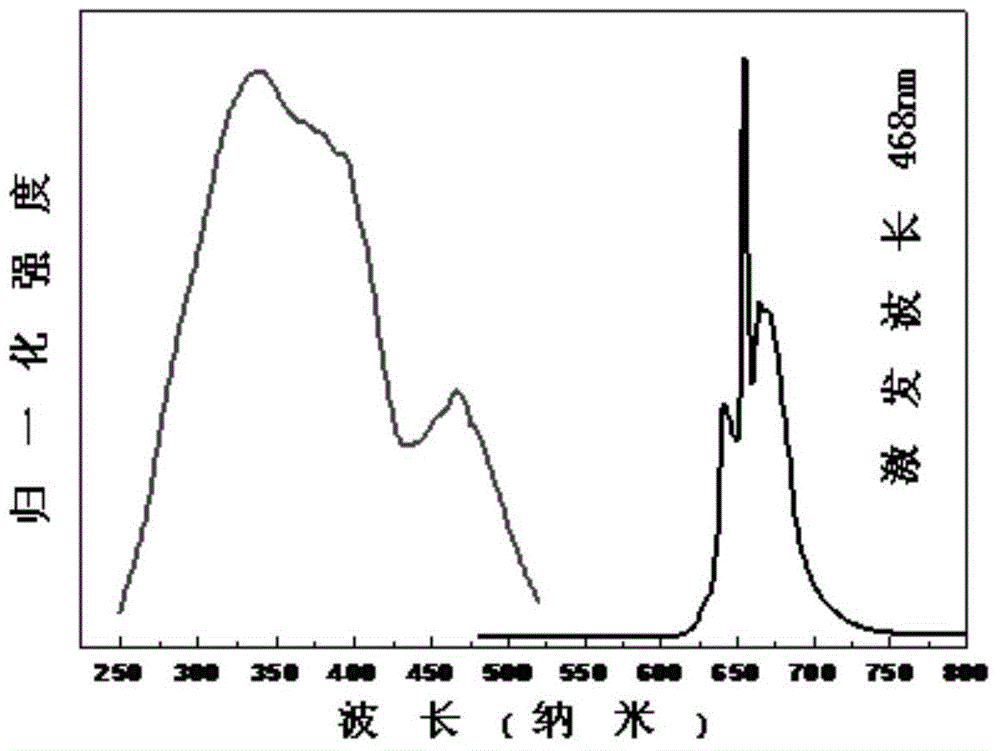

[0023] Example 2: Analytical pure CaCO 3 、Al 2 o 3 , MgO, and MnCO 3 Powder, as CaCO 3 :2MgO:7.992Al 2 o 3 :0.016MnCO 3 The ratio of (molar ratio) is accurately weighed and placed in an agate mortar. Add an appropriate amount of ethanol and grind for 20 minutes to make it evenly mixed; then place it in a 60°C oven for about 2 minutes, take it out, and place Grind in medium for 1 hour, then bake in an oven at 60°C for 10 minutes, take it out and grind for 10 minutes, then put it in a square crucible, heat it to 1450°C in a high-temperature box furnace with program temperature control, keep it for 6 hours, Cool to obtain the sample. Grinding and sieving to obtain phosphor powder, the color of the phosphor powder observed is light pink. According to the results of X-ray diffraction analysis, the phosphor powder obtained is a pure phase of CMA; its excitation and emission spectra at room temperature were measured with a FLS920 fluorescence spectrometer, and it was found th...

example 3

[0024] Example 3: Analytical pure CaCO 3 、Al 2 o 3 , MgO, and MnCO 3 Powder, as CaCO 3 :2MgO:7.76Al 2 o 3 :0.48MnCO 3 The ratio (molar ratio) is accurately weighed and placed in an agate mortar, and an appropriate amount of ethanol is added to grind for 20 minutes to make it evenly mixed; then placed in a 60°C oven for about 3-5 minutes, after taking it out, put it in the grinder Continue to grind in the bowl for 45 minutes, then place it in a square crucible, heat it to 1500°C in a high-temperature program-controlled high-temperature box-type resistance furnace, keep it warm for 2 hours, and cool it with the furnace to obtain a sample. Grinding and passing through a mesh sieve to obtain phosphor powder, the color of the phosphor powder observed is dark red. According to the results of X-ray diffraction analysis, the phosphor powder obtained is a pure phase of CMA; its excitation and emission spectra at room temperature were measured with a FLS920 fluorescence spectrome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com