Method for preparing benzene liquid-phase product by virtue of catalytic cracking of wood-plastic composite

A wood-plastic composite material and catalytic cracking technology, applied in the field of biomass energy utilization, can solve the problems of long reaction period, high production cost, high requirements for reaction equipment and reaction conditions, and achieve short reaction period, resource saving and reaction conditions. less demanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

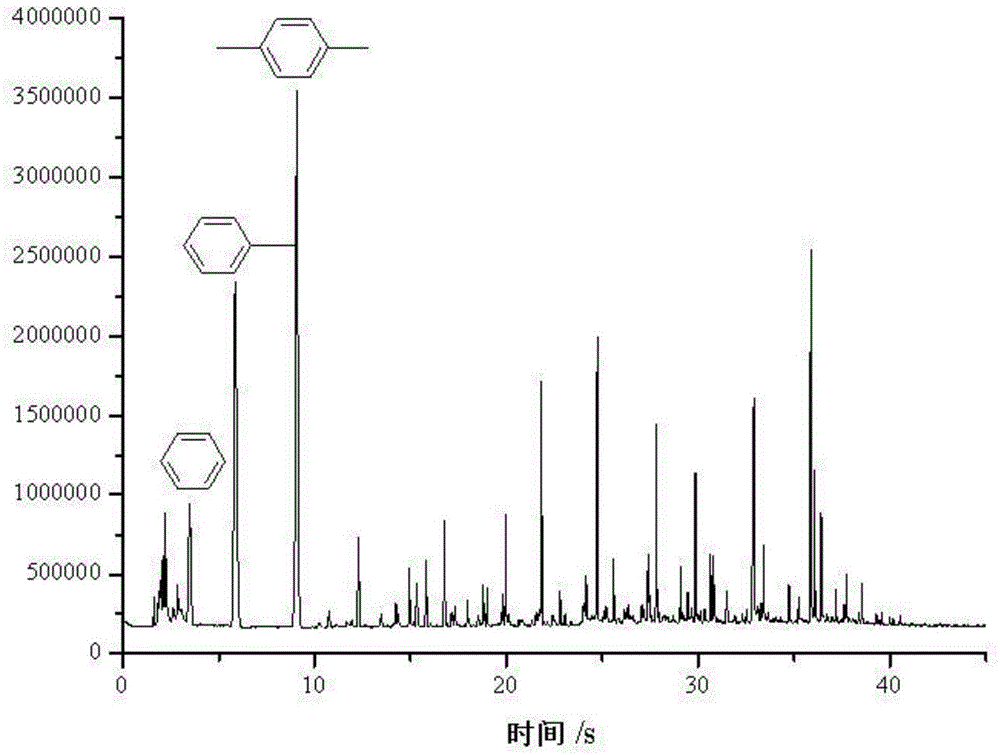

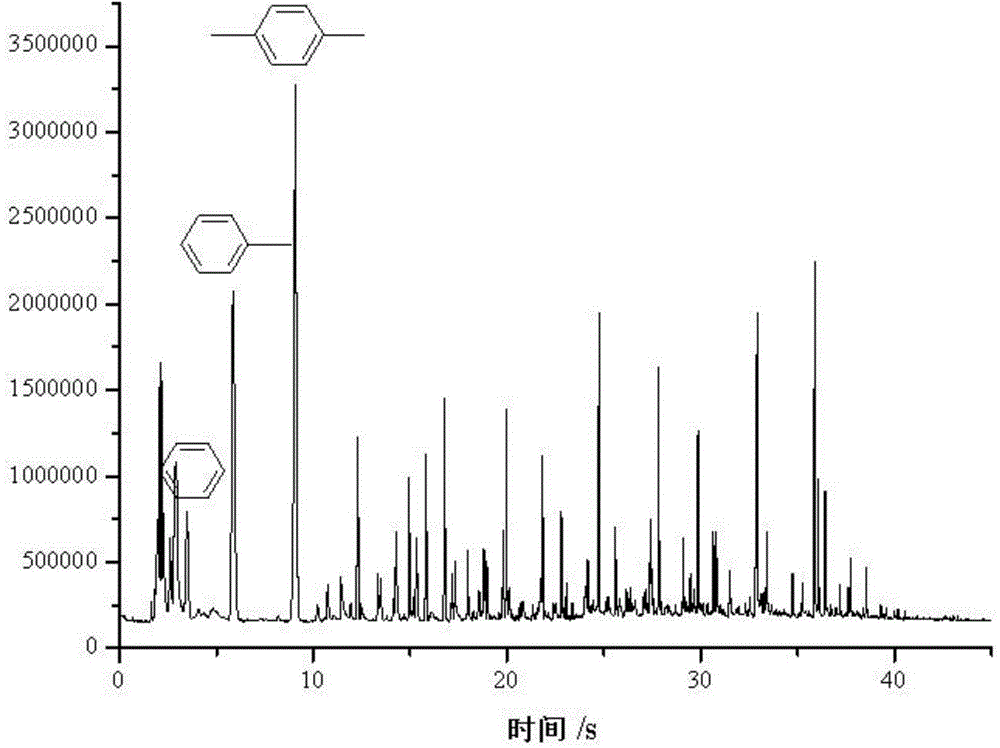

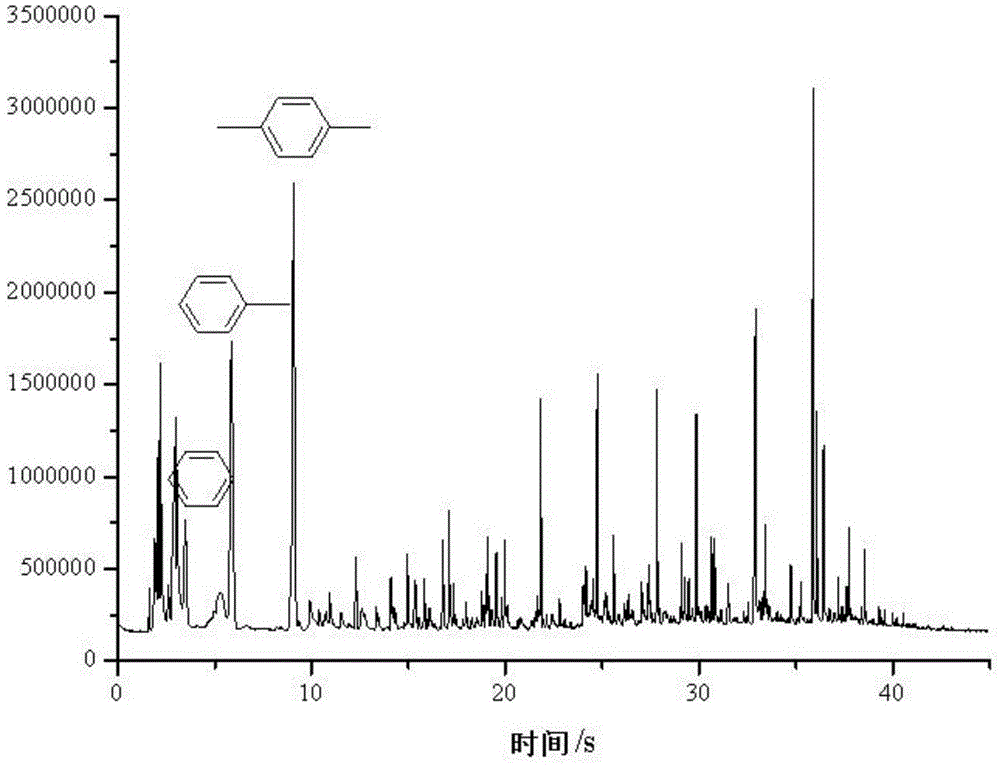

[0016] Specific embodiment 1: In this embodiment, a method for preparing benzene-based liquid phase products by catalytic cracking of wood-plastic composite materials is carried out according to the following steps:

[0017] 1. Under anaerobic conditions, control the temperature at 450°C to 700°C, pyrolyze the wood-plastic composite material, and then separate the gas and solid to obtain high-temperature pyrolysis gas;

[0018] 2. Pass the high-temperature pyrolysis gas obtained in step 1 into a reactor equipped with zeolite molecular sieves for catalytic reaction, and then condense the pyrolysis gas to obtain a benzene-based liquid phase product.

specific Embodiment approach 2

[0019] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the wood-plastic composite material described in step 1 is a composite material of lignocellulose and thermoplastic polymer, wherein the lignocellulose is wood flour, straw or rice Shell, the thermoplastic polymer is PE, PP or PS. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0020] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the mass ratio of lignocellulose and thermoplastic polymer in the wood-plastic composite material described in step 1 is (50-70):(50-30). Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com