Method for producing low temperature-resistance beta-mannase by using enterobacter

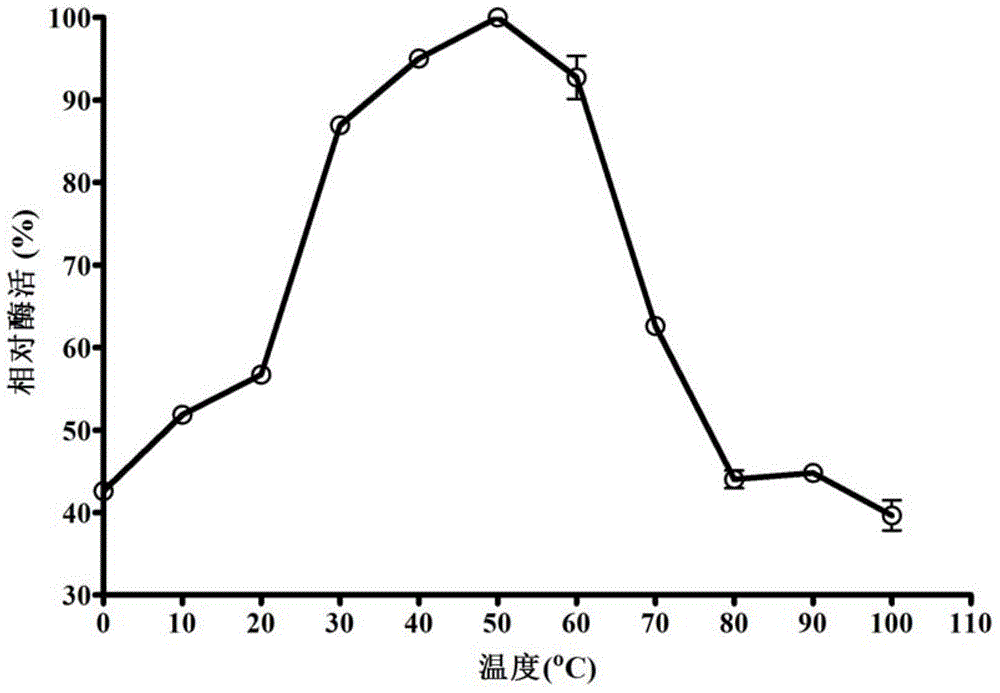

A mannanase and low temperature-resistant technology, which is applied in the field of producing β-mannanase and achieves the effects of high enzyme activity, simple cultivation, wide temperature and pH range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

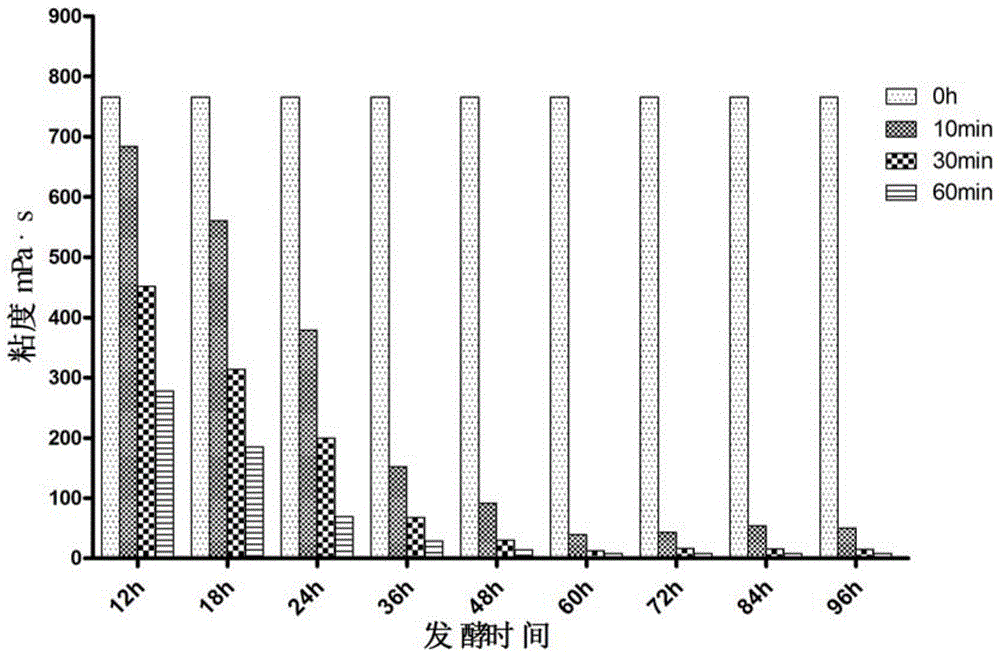

[0029] Fermentation medium (wt%): guar gum 1.0%, NH 4 NO 3 0.1%, KH 2 PO 4 0.245wt%, Na 2HPO 4 12H 2 O 1.0%, MgSO 4 0.01%, yeast powder 0.05%, trace element 10mL (trace element (wt%): MnSO 4 ·H 2 O 0.03%, Na 2 MoO 4 2H 2 O 0.01%, FeSO 4 ·7H 2 O 0.2%, CuSO 4 0.006%, CaCl 2 0.1%). Enterobacter sp.N18 was cultivated in shake flasks at 37° C. at 150 r / min, with an inoculum size of 5%, and cultivated for 48 hours. Using guar gum as a substrate at 50°C, the enzyme activity detected by DNS method was 596.7U / mL; within 24 hours, the viscosity of 1.4% guar gum solution was reduced from 800mPa·s to 78mPa·s, a reduction of 90%.

Embodiment 2

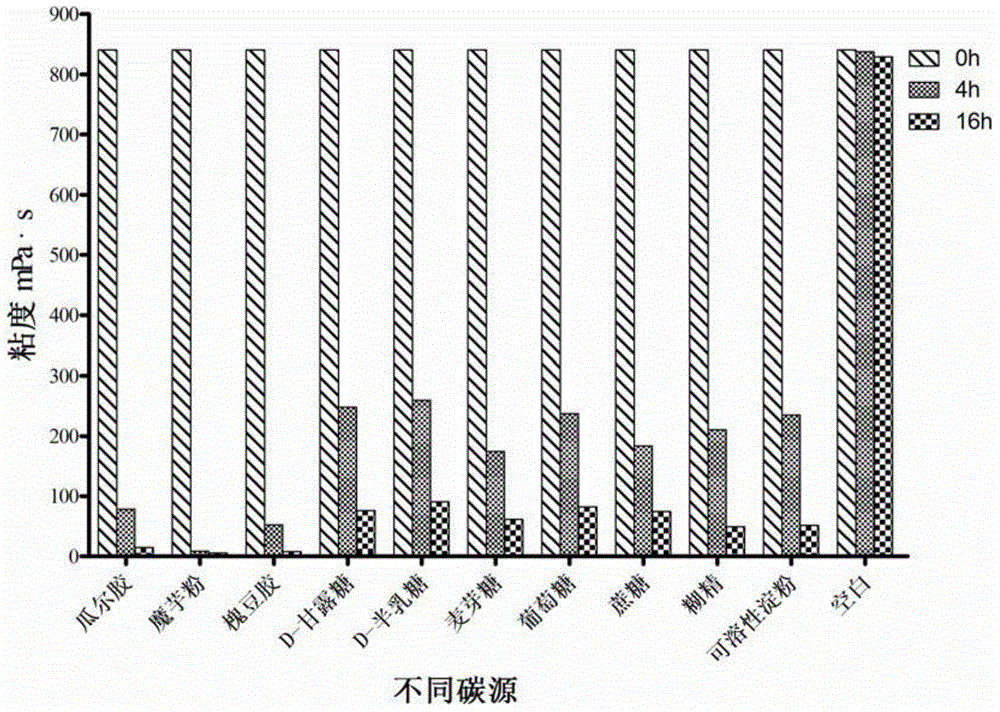

[0031] Fermentation medium (wt%): carbon source 1.0%, NH 4 NO 3 0.1%, KH 2 PO 4 0.245wt%, Na 2 HPO 4 12H 2 O 1.0%, MgSO 4 0.01%, yeast powder 0.05%, trace element 10mL (trace element (wt%): MnSO 4 ·H 2 O 0.03%, Na 2 MoO 4 2H 2 O 0.01%, FeSO 4 ·7H 2 O 0.2%, CuSO 4 0.006%, CaCl 2 0.1%). The carbon sources are guar gum, konjac flour, locust bean gum, D-mannan, D-galactose, maltose, glucose, sucrose, soluble starch, and dextrin. Enterobacteriaceae were cultured in shake flasks at 37°C and 150r / min (Enterobacter sp.N18), the inoculum size was 5%, and cultured for 48 hours. Using guar gum as a substrate at 50°C, the enzyme activity was determined by the DNS method, and the results are shown in Table 1. figure 1 .

[0032] Table 1: Detection results of β-mannanase activity obtained from different carbon sources

[0033] carbon source

[0034] Enzyme activity (U)

[0035] .

Embodiment 3

[0037] Fermentation medium (wt%): konjac flour 0.1~3.0%, NH 4 NO 3 0.1%, KH 2 PO 4 0.245wt%, Na 2 HPO 4 12H 2 O 1.0%, M g SO 4 0.01%, yeast powder 0.05%, trace elements 10 mL (trace elements (wt%): MnSO 4 ·H 2 O 0.03%, Na 2 MoO 4 2H 2 O 0.01%, FeSO 4 ·7H 2 O 0.2%, CuSO 4 0.006%, CaCl 2 0.1%). Enterobacter sp.N18 was cultivated in shake flasks at 37° C. at 150 r / min, with an inoculum size of 5%, and cultivated for 48 hours. Using guar gum as a substrate at 50°C, the enzyme activity was detected by the DNS method, and the results are shown in Table 2.

[0038] Table 2: The enzyme activity detection results of β-mannanase cultured with different concentrations of konjac flour as carbon source

[0039] Konjac flour (wt%)

[0040] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com