Non-contact electrode piezoelectric transducer device for monitoring strongly-corrosive gas and method

A corrosive gas, piezoelectric sensor technology, applied in the direction of using substances to absorb and weigh, can solve the problems of high price of the sensor, interference with the measurement of adsorption capacity, short service life, etc., to expand the linear range and eliminate the measurement error of adsorption capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the drawings and embodiments.

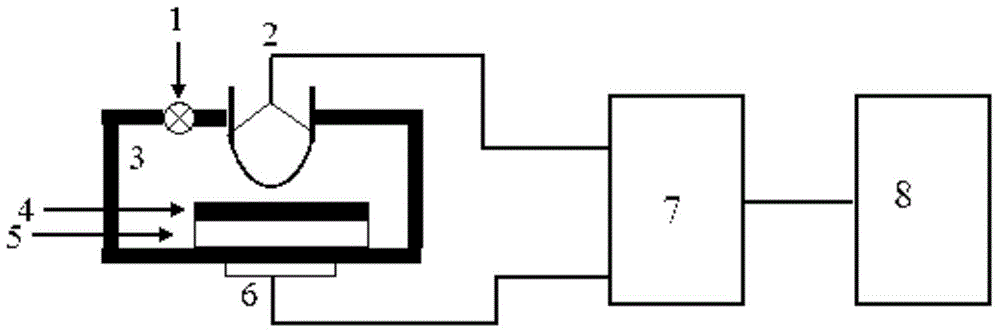

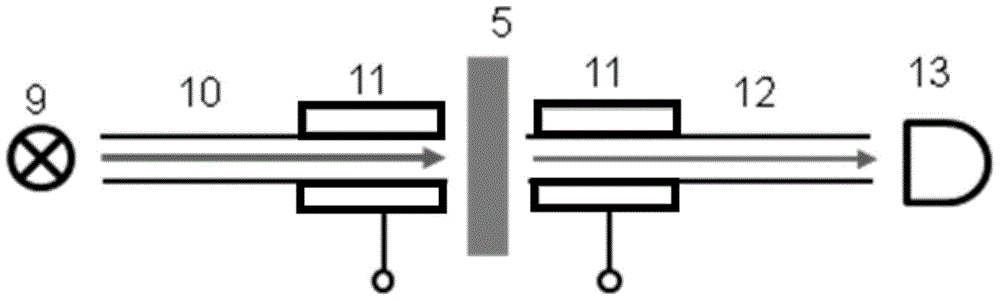

[0035] Such as figure 1 As shown, a non-contact electrode piezoelectric sensor device for monitoring strong corrosive gases includes a piezoelectric quartz wafer 5, an upper excitation electrode with an anti-corrosion design, a lower excitation electrode 6, an adsorption measuring cell 3, a controller 8 and Impedance analyzer 7; two excitation electrodes are respectively installed on the top and bottom of the piezoelectric quartz wafer and separated from the piezoelectric quartz wafer. The upper excitation electrode 2 with anti-corrosion design is encapsulated in a thin-walled glass tube and placed in the adsorption measurement cell , The lower excitation electrode 6 is placed at the bottom of the adsorption measuring cell, and the excitation electric field is applied to the piezoelectric quartz wafer 5 through the conduction of glass and air to make it resonate. The re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com