A kind of enzymatic chemiluminescence substrate solution

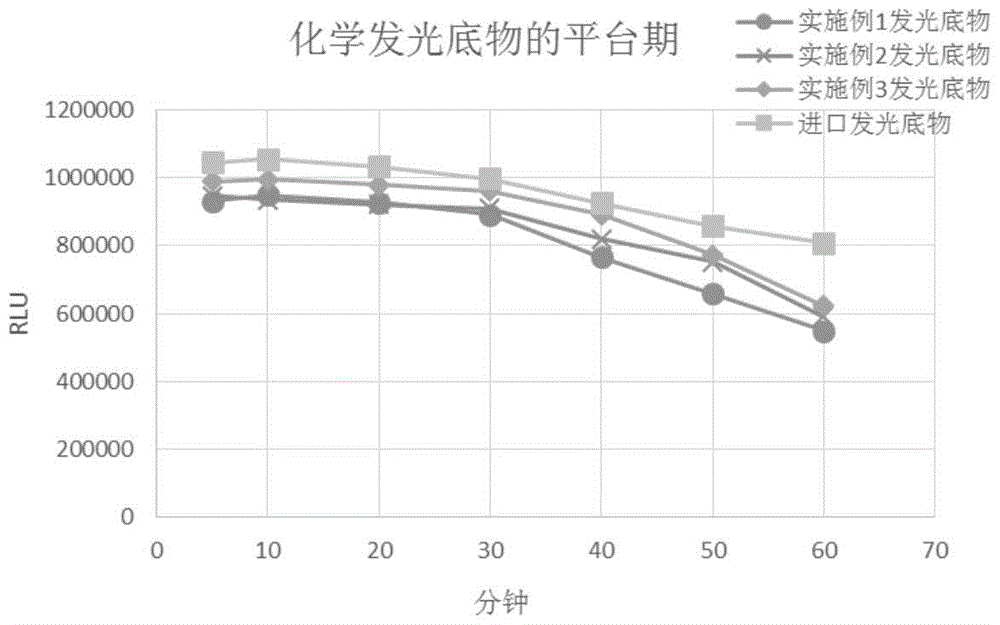

An enzyme-catalyzed chemiluminescence, substrate liquid technology, applied in chemiluminescence/bioluminescence, analysis by chemical reaction of materials, etc., can solve the problem of high reagent cost, inconvenient use in primary clinical hospitals, and inability to meet the high sensitivity of clinical detection. , high specificity requirements and other issues, to achieve the effects of high sensitivity, prolonged luminescence duration, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1, preparation of enzymatic chemiluminescent substrate solution 1 of the present invention

[0044] (1) Preparation of enzymatic chemiluminescent substrate solution A:

[0045] Weigh 0.0094g carbamide peroxide (Sigma Company 289132), 0.01g sodium tetrapolyphosphate (Shanghai Huikai Company 7727-67-5), 0.03g sodium fluoride (Sinopharm Reagent 10019608), 0.01g sodium tartrate (Sinopharm Reagent 30169816 ), 0.172g citric acid (C6H 8 o 7 ·H 2 O national medicine reagent 10007108), 0.347g sodium citrate (Na 3 C 6 h 5 o 7 2H 2 O National Medicine Reagent 10019428), adjust the pH to 5.0, and settle to 100ml with purified water.

[0046] The concentration of each component in the enzymatic chemiluminescent substrate solution A liquid prepared by the above method is as follows:

[0047] Carbamide peroxide, concentration: 1mM;

[0048] Sodium tetrapolyphosphate, the mass percentage concentration is: 0.01%;

Embodiment 2

[0061] Embodiment 2, preparation of enzymatic chemiluminescent substrate solution 2 of the present invention

[0062] (1) Preparation of enzymatic chemiluminescent substrate solution A:

[0063] Weigh 0.094g carbamide peroxide (Sigma Company 289132), 0.05g sodium tetrapolyphosphate (Shanghai Huikai Company 7727-67-5), 0.05g sodium fluoride (Sinopharm Reagent 10019608), 0.1g sodium tartrate (Sinopharm Reagent 30169816 ), 0.172g citric acid (C6H 8 o 7 ·H 2 O national medicine reagent 10007108), 0.347g sodium citrate (Na 3 C 6 h 5 o 7 2H 2 O National Medicine Reagent 10019428), adjust the pH to 5.0, and settle to 100ml with purified water.

[0064] The concentration of each component in the enzymatic chemiluminescent substrate solution A liquid prepared by the above method is as follows:

[0065] Carbamide peroxide, concentration: 10mM;

[0066] Sodium tetrapolyphosphate, the mass percentage concentration is: 0.05%;

[0067] Sodium fluoride, mass percent concentration:...

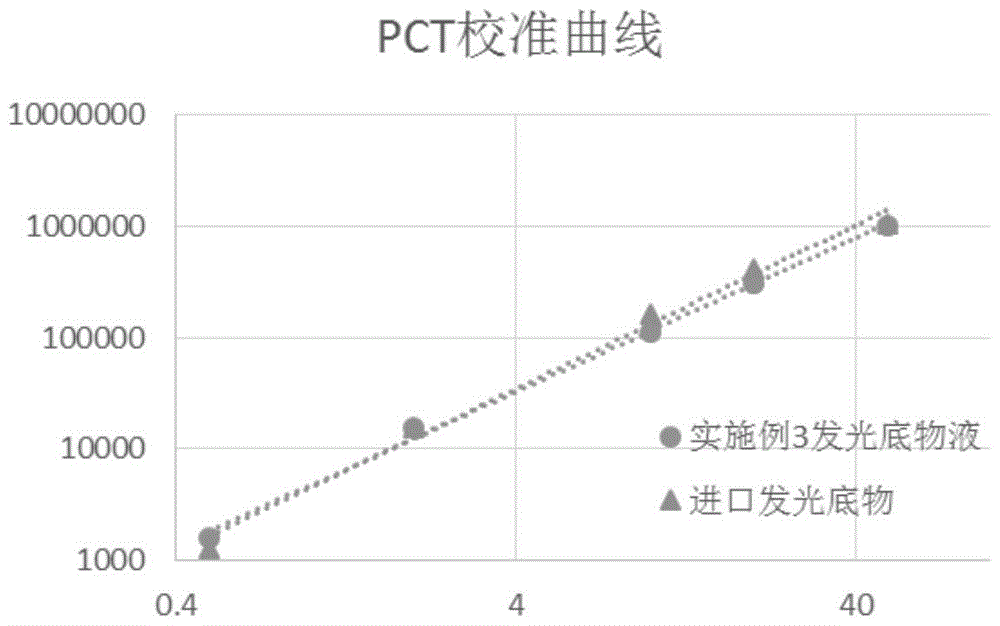

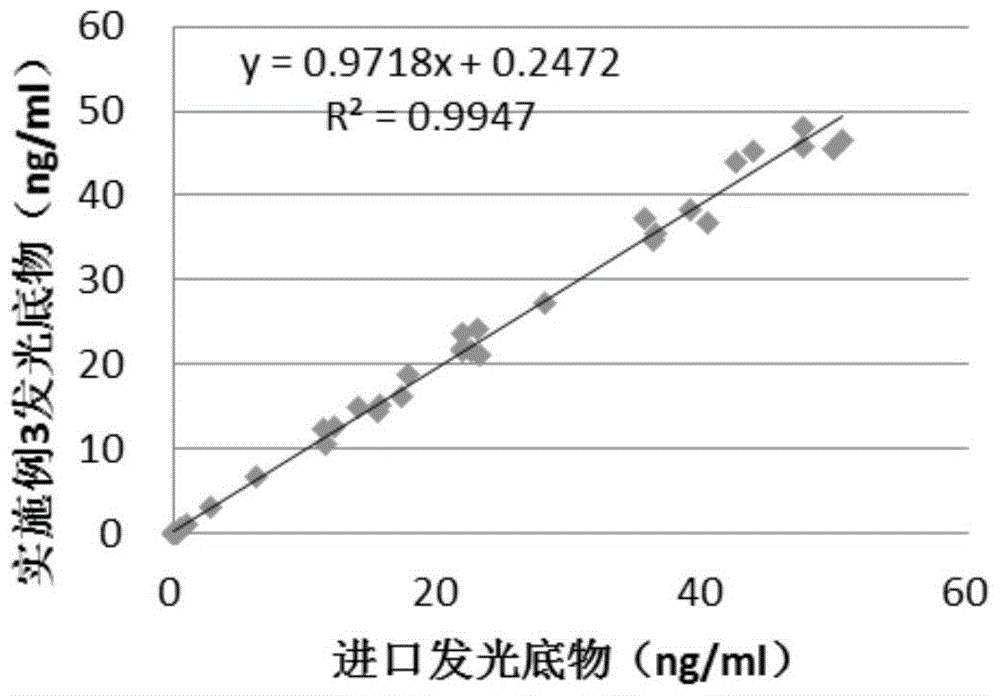

Embodiment 3

[0079] Embodiment 3, preparation of enzymatic chemiluminescent substrate solution 3 of the present invention

[0080] (1) Preparation of enzymatic chemiluminescent substrate solution A:

[0081] Weigh 0.047g carbamide peroxide (Sigma Company 289132), 0.03g sodium tetrapolyphosphate (Shanghai Huikai Company 7727-67-5), 0.04g sodium fluoride (Sinopharm Reagent 10019608), 0.06g sodium tartrate (Sinopharm Reagent 30169816 ), 0.172g citric acid (C6H 8 o 7 ·H 2 O national medicine reagent 10007108), 0.347g sodium citrate (Na 3 C 6 h 5 o 7 2H 2 O National Medicine Reagent 10019428), adjust the pH to 5.0, and settle to 100ml with purified water.

[0082] The concentration of each component in the enzymatic chemiluminescent substrate solution A liquid prepared by the above method is as follows:

[0083] Carbamide peroxide, the concentration is: 5mM;

[0084] Sodium tetrapolyphosphate, the mass percentage concentration is: 0.03%;

[0085] Sodium fluoride, mass percent concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com