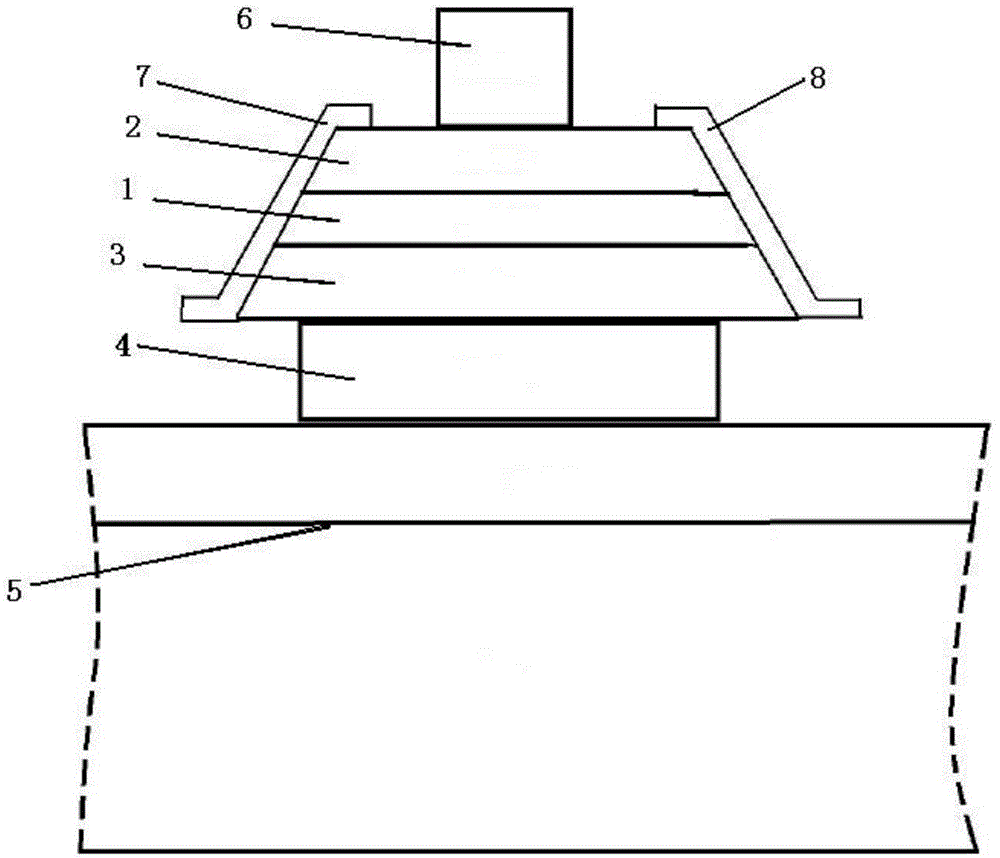

Graphene field effect transistor structure and large-scale manufacturing process thereof

A field-effect transistor and manufacturing process technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as high process difficulty, poor performance, and low yield rate, and achieve the effect of overcoming high process difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

[0028] h-BN is a dielectric material with a band gap of about 5.9eV. Its lattice structure is very similar to graphene, and its surface is also a two-dimensional planar structure. There are no surface dangling bonds and internal charged defects. Graphene is an ideal substrate material. And because the lattice mismatch between h-BN and graphene is small, and the surface is smooth without dangling bonds, the carrier mobility of field effect transistors using h-BN as gate dielectric is higher than that of traditional SiO2 or A field effect transistor with SiC as the substrate and Al2O3 as the gate dielectric. Edge contact, namely 1D contact, is a technology that deposits wires on the edge of the channel material to achieve electrical contact. Graphene lacks surface binding sites, and the strong orbital hybridization and (and intermetallic) lack of chemical bonding in it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com