Formed fermented glutinous rice and production process thereof

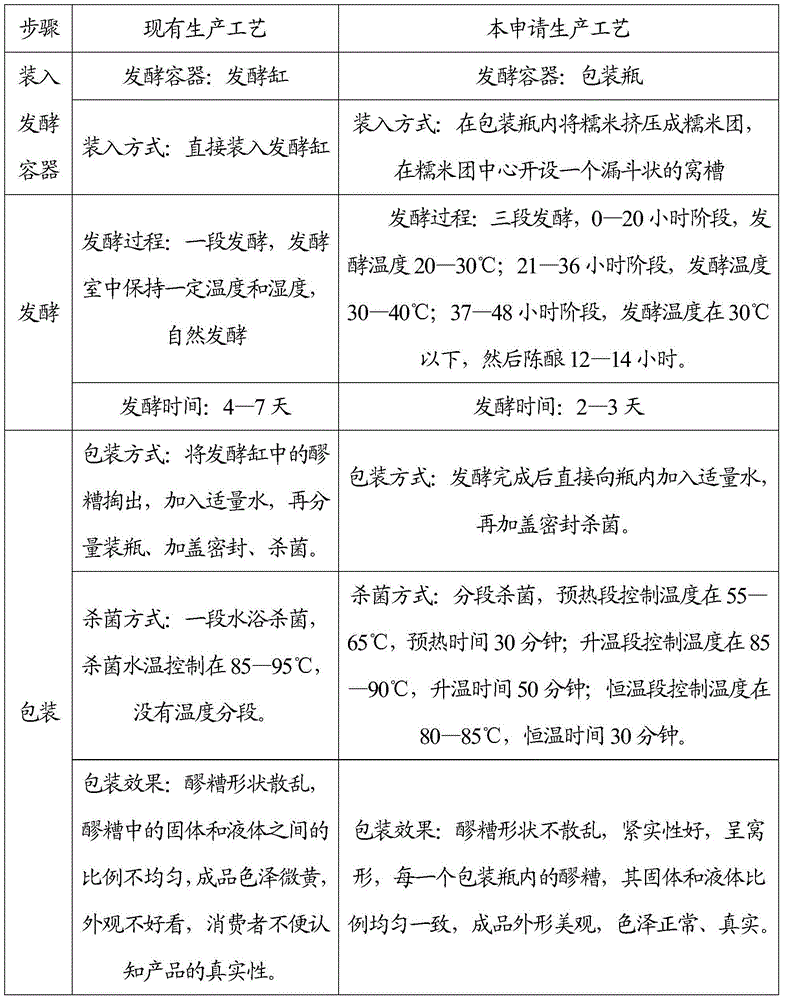

A production process and mash technology, which are applied in the field of forming mash and its production technology, can solve the problems of poor control of specific parameters, unstable flavor of the finished product, scattered and unformed mash, etc., and achieve the finished product with beautiful appearance, beautiful appearance and shape, and taste and flavor. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A production process of molded fermented glutinous rice, its specific steps are:

[0026] (1) Soaking: the glutinous rice after screening is soaked after mixing according to the ratio of glutinous rice and water weight ratio of 1:1, and the soaking time is 12 hours;

[0027] (2) Cooking: the soaked glutinous rice is placed in a steamer, the pressure of the steamer is 0.15Mpa, the cooking temperature is 110°C, and the cooking time is 6 minutes. After the glutinous rice is steamed, cool down to normal temperature;

[0028] (3) Mix koji: mix the steamed glutinous rice evenly with a weight ratio of 1:0.005 between glutinous rice and koji medicine, wherein the koji medicine is composed of yeast and rhizopus;

[0029] (4) bottling: put the glutinous rice after the koji into a sterilized packaging bottle, squeeze the glutinous rice into glutinous rice balls in the packaging bottle, and open a funnel-shaped nest at the center of the glutinous rice balls by a shaper. The depth ...

Embodiment 2

[0038] Using the process described in Example 1, four batches of molded fermented glutinous rice, numbered A, B, C, and D, were subjected to physical and chemical tests, and the results are shown in Table 2.

[0039] Among them, the reducing sugar is measured by the Lian-Ainong method, the total acid is measured by the GB / T13662-2000 method, and the sugar-acid ratio is: total reducing sugar / total acid content.

[0040]Table 2 Example 2 Fermented glutinous rice finished product physicochemical test result

[0041]

[0042] From the above data, it can be seen that the finalized fermented glutinous rice produced by the technical solution of the present application has a moderate sugar-acid ratio, and shows a sweet but not greasy flavor with moderate acidity from the senses. While ensuring the setting effect, it can achieve a good fermented glutinous rice flavor, so this production process has the practicability of food production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com