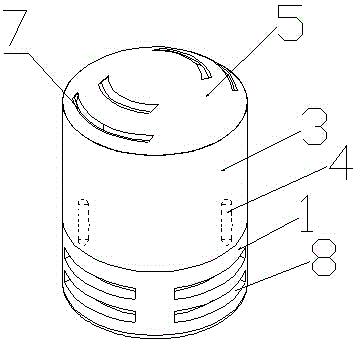

Liquid air purifier

A liquid air and purifier technology, which is applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of poor purification effect, inability to achieve purification effect, and high price of purifiers, and achieve easy replacement and maintenance. Low cost of use, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In this example, the raw materials (wt.%) of the porous ceramic filter layer consist of 50% quartz sand, 30% finely ground diatomite, 7.5% finely ground clay, 2.5% white carbon black, and 10% porogen. The porogen includes fibrous cellulose pulp and ammonium bicarbonate, the particle size of quartz sand is 100-200 microns, the particle size of finely ground diatomaceous earth and finely ground clay is 1-10 micron, and the fibrous cellulose pulp and The mass ratio of ammonium bicarbonate added is 1:2.

[0042] When the dry body is sintered after processing: the carbonization step is sintering at an average temperature of 600-650 degrees Celsius for 15 minutes in an oxygen-poor environment, the oxygen-deficient sintering step is 3.7 hours of oxygen-depleted flame burning at an average temperature of 1300-1400 degrees Celsius, and the oxygen-enriched sintering step Burning with an oxygen-enriched flame for 55 minutes at an average temperature of 800-850 degrees Celsius.

...

Embodiment 2

[0045] In this example, the raw material (wt.%) of the porous ceramic filter layer is composed of 60% quartz sand, 25% finely ground diatomite, 5% finely ground clay, 3% white carbon black and 7% porogen, wherein The porogen includes fibrous cellulose pulp and ammonium bicarbonate, the particle size of quartz sand is 100-200 microns, the particle size of finely ground diatomaceous earth and finely ground clay is 1-10 micron, and the fibrous cellulose pulp and The mass ratio of ammonium bicarbonate added is 1:3.

[0046] When the dry body is sintered after processing: the carbonization step is sintering at an average temperature of 650-700 degrees Celsius for 18 minutes in an oxygen-poor environment; Burn with an oxygen-enriched flame for 60 minutes at an average temperature of 850-950 degrees Celsius.

[0047] The open porosity of the porous ceramic filter layer that present embodiment obtains obtains 37.5%; Density 0.64g / cm 3 ;Strength 5.4MPa, no residue, deformation, unifo...

Embodiment 3

[0049] In this example, the raw material (wt.%) of the porous ceramic filter layer is composed of 55% quartz sand, 20% finely ground diatomite, 15% finely ground clay, 2% white carbon black and 8% porogen, wherein The porogen includes fibrous cellulose pulp and ammonium bicarbonate, the particle size of quartz sand is 100-200 microns, the particle size of finely ground diatomaceous earth and finely ground clay is 1-10 micron, and the fibrous cellulose pulp and The mass ratio of ammonium bicarbonate added is 1:4.

[0050] When the dry body is sintered after processing: the carbonization step is sintering at an average temperature of 700-750 degrees Celsius for 20 minutes in an oxygen-poor environment, the oxygen-deficient sintering step is 3.2 hours of oxygen-depleted flame burning at an average temperature of 1500-1600 degrees Celsius, and the oxygen-enriched sintering step Burning with an oxygen-enriched flame at an average temperature of 950-1050 degrees Celsius for 50 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com