System for comprehensively controlling heavy metal pollutants in flue gas of coal-fired power plant

A technology for coal-fired power plants and heavy metals, which is applied in the directions of combination devices, separation methods, lighting and heating equipment, etc., can solve problems such as single effect, and achieve the effect of outstanding effect, reasonable disposal and emission reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

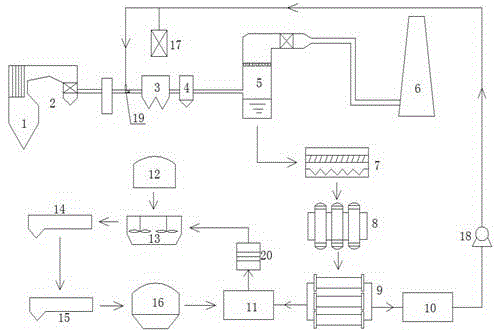

[0025] as attached figure 1 As shown, the coal-fired power plant flue gas heavy metal pollutant comprehensive interception and control system provided by the present invention includes an SCR reaction zone connected with a coal-fired boiler, and the SCR reaction zone is connected to an electric dust collector, a bag filter and a desulfurization reaction zone in sequence, and the desulfurization The slurry in the reaction zone is added with an oxidant or metal complexing agent, and the slurry in the desulfurization reaction zone is added with a flocculant and then connected to the clarification filter and the ultrafiltration unit in turn, and the supernatant from the ultrafiltration unit is adjusted to pH 6. Connected with the reverse osmosis unit, the high-chloride and high-calcium concentrate from the reverse osmosis unit passes through the concentrated water tank, delivery pump, atomizing nozzle and the flue between the SCR reaction zone and the electrostatic precipitator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com