A method of electrocatalysis and algae participating in the utilization of oily wastewater

An electrocatalysis and algae technology, which is applied in the preparation of liquid hydrocarbon mixtures, the treatment of hydrocarbon oil, and the petroleum industry, can solve the problems of difficult oily wastewater treatment, low utilization efficiency, and high application value, and achieve the reduction of repolymerization reactions and the degree of applicability High, reduce the effect of waste disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

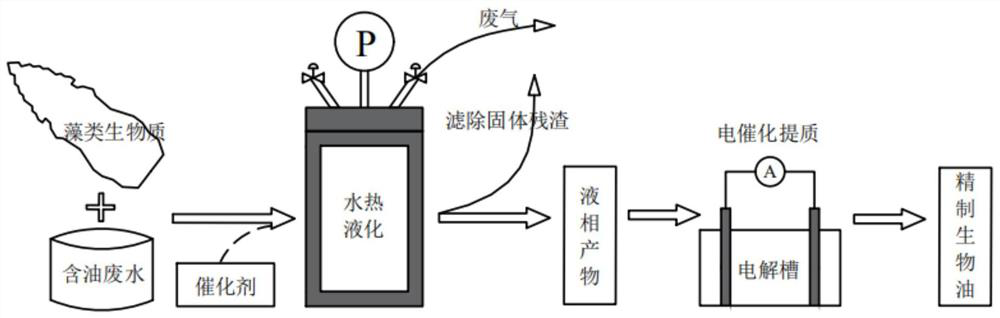

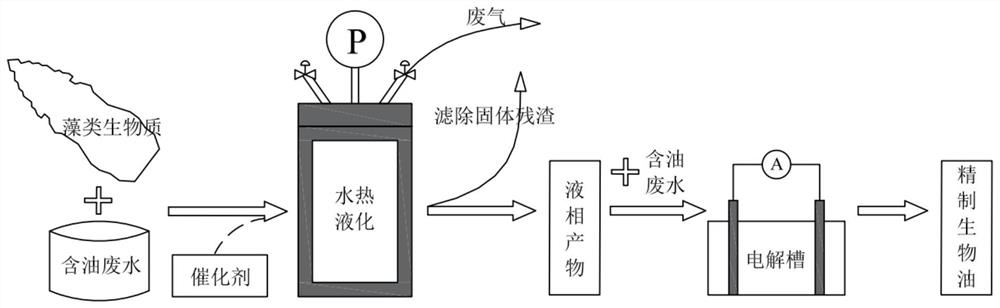

[0023] Such as figure 1 As shown, a kind of electrocatalysis combined algae designed in the present invention participates in the method for the utilization of oily wastewater, the specific process is as follows:

[0024] Preparation of raw materials: the algae used in the embodiment of the present invention is the large seaweed Enteromorpha enteromorpha, and microalgae such as chlorella can also be used; the oily wastewater used comes from a mechanical processing plant.

[0025] Hydrothermal liquefaction: Mix Enteromorpha enteromorpha and oily wastewater at a mass ratio of 1:1, add them to an int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com