Method for extracting silane from epitaxial process tail gas by full-temperature-range pressure swing adsorption

A technology of pressure swing adsorption and full temperature range, applied in separation methods, chemical instruments and methods, silicon hydride, etc., to achieve the effect of reducing tail gas emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

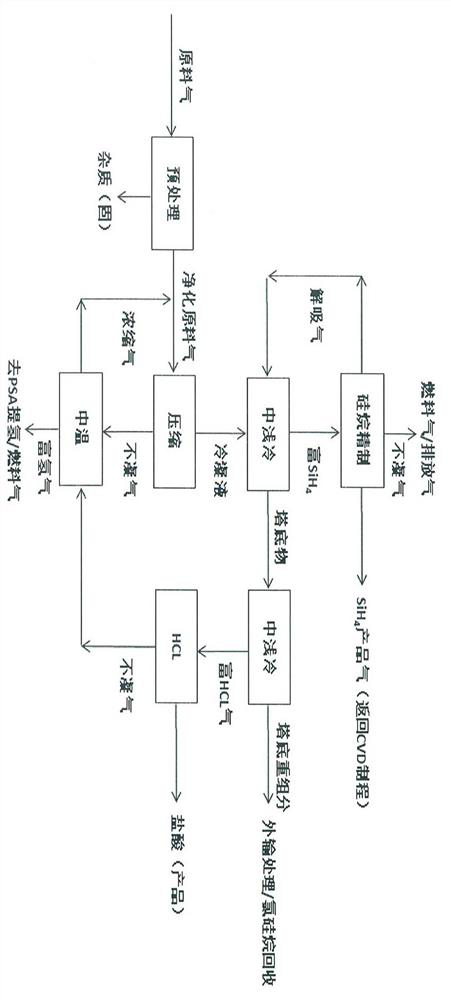

[0038] Such as figure 1 As shown, a method for extracting silane by full-temperature pressure swing adsorption of epitaxial process tail gas, the specific implementation steps include,

[0039] (1) Raw material gas, based on silane (SiH4) as the main source of "silicon (Si)", methane (CH4) as the main source of "carbon (C)", and hydrogen chloride (HCl) as the main chlorine-based compound, and The tail gas produced in the chlorine-based Si / SiC epitaxial growth process based on silicon carbide (SiC) is prepared by chemical vapor deposition (CVD) with inert hydrogen (H2) as the carrier gas. The main components are H2, HCl, CH4 and SiH4. A small amount of SiHmCln, C2+, and a small amount of carbon monoxide (CO), carbon dioxide (CO2), water (H2O), and silicon dioxide (SiO2) and carbon (C) fine particles, at normal pressure and temperature.

[0040] (2) Pretreatment, the raw gas is sent to the pretreatment unit composed of dust collector, particle removal filter and oil mist collec...

Embodiment 2

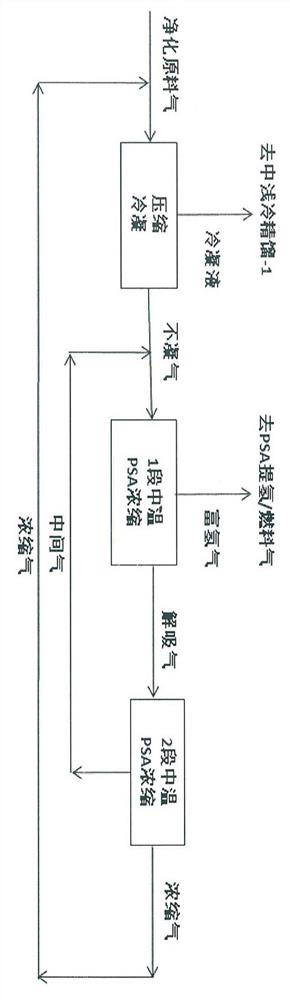

[0047] Such as figure 2 As shown, on the basis of Example 1, the non-condensable gas from the compression condensation process is directly sent to the medium-temperature pressure swing adsorption concentration process composed of the two-stage PSA system after the cold and heat exchange, and the non-condensable gas is adsorbed from the first PSA The bottom of the tower (1-stage PSA) enters, and the non-adsorbed phase gas flowing out from the top of the 1-stage PSA tower is hydrogen-rich gas, which is output as the raw material gas for PSA hydrogen extraction for hydrogen extraction, and is desorbed from the bottom of the 1-stage PSA tower (reverse discharge, flushing or vacuum), the desorbed gas flowing out is pressurized and sent to the bottom of the second PSA adsorption tower (2-stage PSA), and the non-adsorbed phase gas flowing out from the top of the 2-stage PSA tower is the intermediate gas, which is returned to the inlet of the 1-stage PSA Feed gas - non-condensable ga...

Embodiment 3

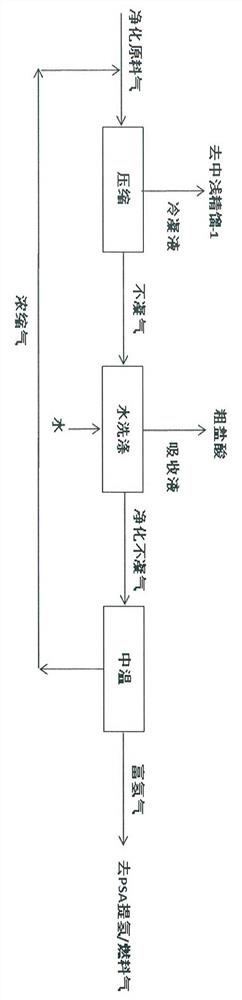

[0049] Such as image 3 As shown, on the basis of Example 1, a water scrubber is added between the medium-temperature pressure swing adsorption concentration process and the compression condensation process, and the non-condensable gas from the compression condensation process first enters the scrubbing absorption tower with an operating temperature of 60-80 ° C. Water is the absorbent, which is sprayed down from the top of the washing and absorbing tower, and the non-condensable gas flows in from the bottom of the tower, and the purified non-condensable gas flowing out from the top of the washing and absorbing tower from the removal of HCl enters the medium temperature pressure swing adsorption for concentration, and flows from the washing and absorbing tower The crude hydrochloric acid flows out from the bottom and is exported.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com