Catalyst for synthesis of 2,6-dimethyl-4-heptanone from acetone and preparation method for catalyst

A technology of diisobutyl ketone and catalyst, which is applied in the field of catalyst and preparation, can solve many problems, and achieve the effects of improving selectivity, improving conversion rate and selectivity, and improving activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

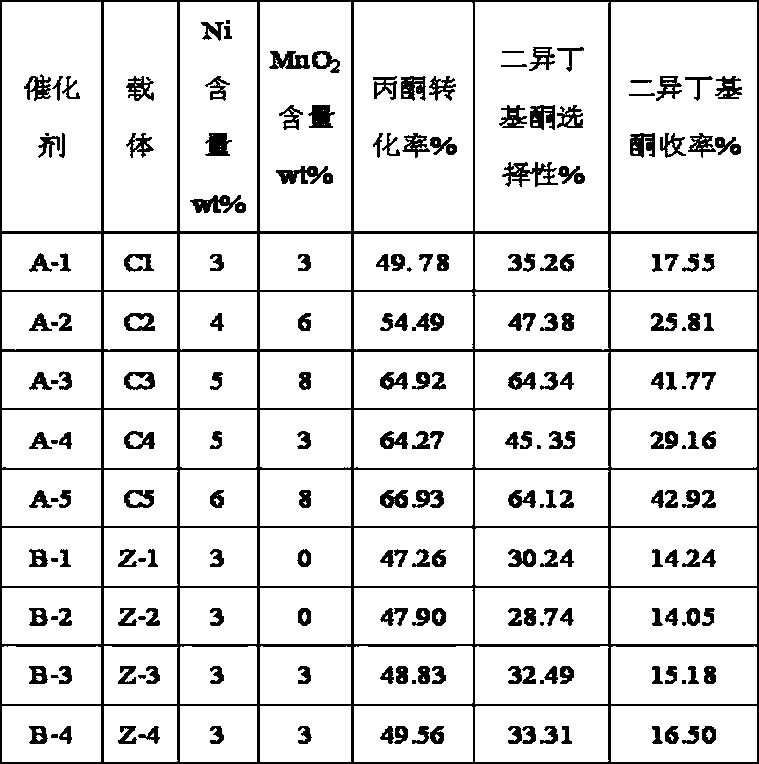

Examples

Embodiment 1

[0030] 262g ZrOCl 2 ·8H 2 O and 8g MnCl 2 4H 2 O was dissolved in 1000mL deionized water to make a mixed solution. Add the mixed salt solution dropwise to 800 mL of 0.2 mol / L ammonia solution, and simultaneously add 0.2 mol / L NaOH solution dropwise to control the pH to 11. After the dropwise addition, stir for 40 minutes, then statically settle and age in the mother liquor at room temperature for 24 hours to obtain Zr(OH) 4 with Mn(OH) 2 Mix hydrogel. Zr(OH) 4 with Mn(OH) 2 The hybrid hydrogels were washed with deionized water until Cl-free - Existence, filter to get the precipitate, the precipitate is dried at 110°C for 6 hours, and roasted at 300°C for 8 hours to get ZrO 2 -MnO 2 Carrier C-1.

[0031] 16gNi(NO 3 ) 2 ·6H 2 O and 3gNH 4 NO 3Dissolve in 130mL of distilled water to make an impregnating liquid, soak 100g C-1 in the impregnating liquid for 24 hours, pour off the upper layer of water, dry at 110°C for 3 hours, and bake at 400°C for 8 hours. Cat...

Embodiment 2

[0033] 185gZrCl 4 and 16gMnCl 2 4H 2 O was dissolved in 1000mL deionized water to make a mixed solution. Add the mixed salt solution dropwise to 800 mL of 0.2 mol / L ammonia solution, and simultaneously add 0.2 mol / L NaOH solution dropwise to control the pH to 11. After the dropwise addition, stir for 40 minutes, then statically settle and age in the mother liquor at room temperature for 24 hours to obtain Zr(OH) 4 with Mn(OH) 2 Mix hydrogel. Zr(OH) 4 with Mn(OH) 2 The hybrid hydrogels were washed with deionized water until Cl-free - Existence, filter to get the precipitate, the precipitate is dried at 110°C for 6 hours, and roasted at 300°C for 8 hours to get ZrO 2 -MnO 2 Carrier C-2.

[0034] 22gNi(NO 3 ) 2 ·6H 2 O and 3gNH 4 NO 3 Dissolve it in 130mL of distilled water to make an impregnating solution. Immerse 100g of C-3 in the impregnating solution for 24 hours, pour off the upper layer of water, dry at 110°C for 3 hours, and bake at 400°C for 8 hours. ...

Embodiment 3

[0036] 250gZrOCl 2 ·8H 2 O and 28gMn(NO 3 ) 2 4H 2 O was dissolved in 1000mL deionized water to make a mixed solution. Add the mixed salt solution dropwise to 800 mL of 0.2 mol / L ammonia solution, and simultaneously add 0.2 mol / L NaOH solution dropwise to control the pH to 11. After the dropwise addition, stir for 40 minutes, then statically settle and age in the mother liquor at room temperature for 24 hours to obtain Zr(OH) 4 with Mn(OH) 2 Mix hydrogel. Zr(OH) 4 with Mn(OH) 2 The hybrid hydrogels were washed with deionized water until Cl-free - Existence, filter to get the precipitate, the precipitate is dried at 110°C for 6 hours, and roasted at 300°C for 8 hours to get ZrO 2 -MnO 2 Carrier C-3.

[0037] 24gNi(CH 3 COO) 2 4H 2 O and 3.5g CH 3 COONH 4 Dissolve it in 150mL of distilled water to make an impregnating liquid. Immerse 100g of C-3 in the impregnating liquid for 24 hours, pour off the upper layer of water, dry at 110°C for 3 hours, and bake at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com