Alkane isomerization catalyst and preparation method and application thereof

A catalyst and alkane technology, applied in the field of lubricating oil isomerization dewaxing catalyst and its preparation, can solve the problems of prolonging the process flow, increasing the difficulty of operation, increasing the investment cost, etc., to reduce cracking reaction, avoid aggregation, and achieve high viscosity index. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

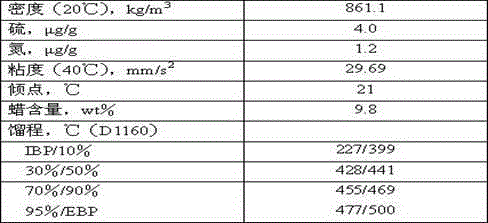

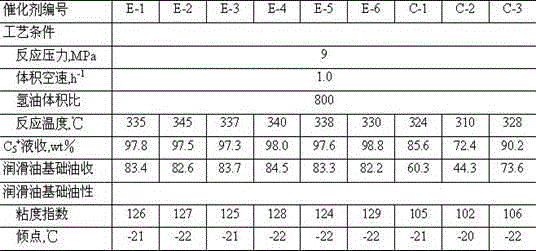

Examples

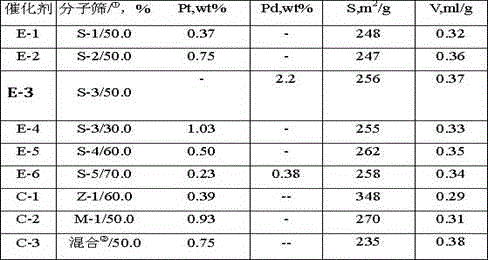

Embodiment 1

[0023] 4.26g NaAlO 2 Mix evenly with 19.08g of sodium hydroxide solution in a 500ml stainless steel reaction kettle, add 53g of silica gel, 408.2g of deionized water, and 18.96g of HMI into the kettle in sequence under stirring, and then add 1.65g of CH 3 1, finally add 55g ZSM-22 again. After continuing to stir for 10 minutes, the reaction vessel was sealed and crystallized at 120° C. for 15 hours. After the crystallization was completed, a solid product (MCM-22 / ZSM-22) was isolated, numbered S-1, and the weight content of MCM-22 was 25.4%.

Embodiment 2

[0025] 1.488g NaAlO 2 Mix evenly with 36.06g sodium hydroxide solution in a 500ml stainless steel reaction kettle, mix 33g silica gel, 3.3gCHCl under stirring 3、 Add 359.3g deionized water and 3.00g HMI to the kettle in turn, and finally add 100g ZSM-22. After continuing to stir for 10 minutes, the reaction vessel was sealed and crystallized at 130° C. for 20 h. After the crystallization was completed, a solid product (MCM-22 / ZSM-22) was isolated, numbered S-2, and the weight content of MCM-22 was 11.1%.

Embodiment 3

[0027] 1.136g NaAlO 2 Mix evenly with 24.04g of sodium hydroxide solution in a 500ml stainless steel reaction kettle, add 22g of silica gel, 237g of deionized water, 12g of HMI and 6g of cyclohexane into the kettle in sequence while stirring, and finally add 120g of ZSM-22. After continuing to stir for 10 minutes, the reaction vessel was sealed and crystallized at 120° C. for 15 hours. After the crystallization was completed, a solid product (MCM-22 / ZSM-22) was isolated, numbered S-3, and the weight content of MCM-22 was 7.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com