Method for deep treatment of biochemical tail water of coking wastewater

A technology for advanced treatment of coking wastewater, which is applied in the field of wastewater treatment and advanced treatment of coking wastewater. It can solve the problems of secondary pollution effluent COD concentration, etc., and achieve the effects of reducing pollutant dissipation, accelerating sedimentation speed, and reducing effluent COD.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

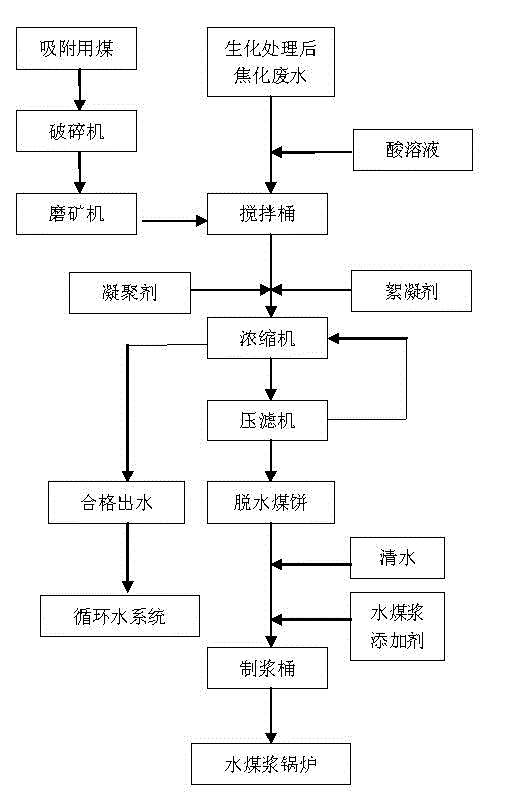

[0024] figure 1 The method for advanced treatment of coking wastewater biochemical tail water in this embodiment includes:

[0025] (1) Feed the long-flame coal as the coal for adsorption into the crusher for crushing to obtain a crushed product with a particle size of 3mm;

[0026] (2) Feed the crushed product into the ore mill for grinding to obtain a grinding product with a particle size of less than 200 mesh and a material content of 80wt%, that is, pulverized coal;

[0027] (3) Send biochemically treated coking wastewater with a chemical oxygen demand (COD) value of 198mg / L into the mixing tank, and add sulfuric acid solution into the mixing tank to adjust the pH value of the water to 3. 2) Add the grinding product in the amount of 30g / L into the mixing tank 7 for stirring and mixing to obtain the stirring product;

[0028] (4) Send the stirred product from step (3) into a concentrator for concentration, and add polyaluminum sulfate 600g / t dry coal powder and polyacryla...

Embodiment 2

[0033] (1) Feed the coking raw material coal of the coking plant into the grinding machine for grinding, and obtain the grinding product with a particle size of less than 200 mesh and a material content of 83wt%, that is, coal powder;

[0034] (2) Send biochemically treated coking wastewater with a chemical oxygen demand (COD) value of 176mg / L into the mixing tank, and add sulfuric acid solution into the mixing tank to adjust the pH value of the water to 4. 1) The grinding product of 50g / L is added to the mixing tank and stirred and mixed to obtain the stirred product;

[0035](3) Transfer the stirred product from step (2) to the concentrator for concentration, and add polyaluminum sulfate 650g / t dry coal powder and polyacrylamide 40g / t dry coal powder to the concentrator to obtain overflow water and Concentrated underflow;

[0036] (4) Feed the concentrated underflow from step (3) into a filter press for dehydration by pressure filtration to obtain filtrate and dehydrated br...

Embodiment 3

[0039] figure 1 The method for advanced treatment of biochemical tail water of coking wastewater in this embodiment includes,

[0040] (1) Feed the coking coal as the coal for adsorption into the crusher for crushing to obtain a crushed product with a particle size of 5mm;

[0041] (2) Feed the crushed product into the ore mill for grinding to obtain a grinding product with a particle size of less than 200 mesh and a material content of 90wt%, that is, pulverized coal;

[0042] (3) Send biochemically treated coking wastewater with a chemical oxygen demand (COD) value of 234mg / L into the mixing tank, and add sulfuric acid solution into the mixing tank to adjust the pH value of the water body to 5. 2) Add the grinding product in the amount of 75g / L to the mixing tank 7 for stirring and mixing to obtain the stirring product;

[0043] (4) Send the stirred product from step (3) into a concentrator for concentration, and add polyaluminum sulfate 680g / t dry coal powder and polyacry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cod | aaaaa | aaaaa |

| Oxygen consumption | aaaaa | aaaaa |

| Cod | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com