Anti-rutting asphalt mixture and preparation method thereof

An asphalt mixture and anti-rutting technology, which is applied in the field of anti-rutting asphalt mixture and its preparation, can solve the problems of easy crushing, inhalation of workers, and excessive dust, so as to improve compactness and hardness, improve anti-rutting performance, and avoid crushing or dust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

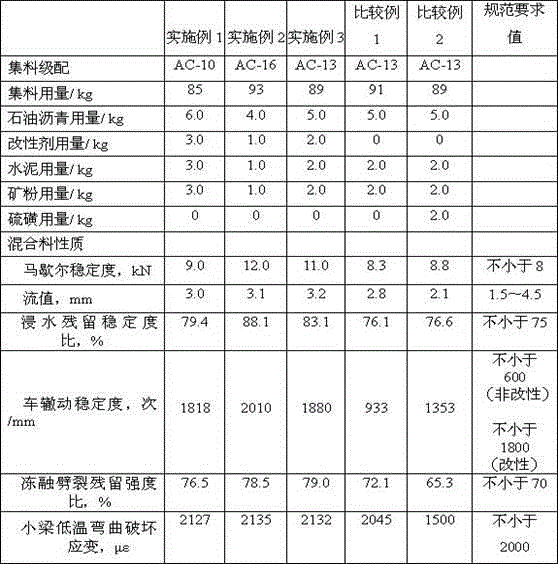

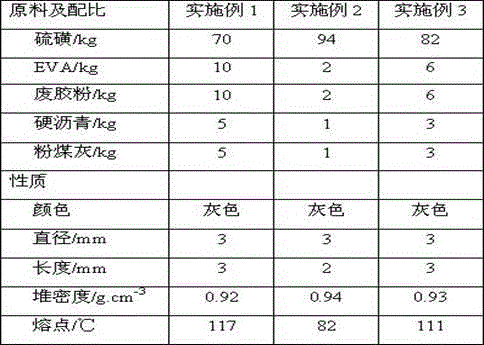

[0040] Weigh 70kg of sulfur, 10kg of EVA (vinyl acetate content of 68%, softening point of 105°C), 10kg of waste rubber powder, 5kg of hard asphalt (natural asphalt with a penetration of 6 1 / 10mm), and 5kg of fly ash. Put the hard asphalt-waste rubber powder-fly ash-sulfur-EVA into the hopper of the kneader in the order, stir evenly and knead the material into a dough shape, and start the vacuum system at the same time to collect the generated gas for environmental protection treatment. Then start the lower discharge screw and the cutting and granulating system to carry out extrusion and granulation to form granules with a diameter of 3 mm and a length of 2 mm to 3 mm to obtain the anti-rutting modifier. The stirring speed of the kneader is 1300 rpm, the stirring time is 30 minutes, the kneading temperature is 80°C, and the extrusion temperature is 120°C. The ratio of raw materials and properties of modifiers are shown in Table 1.

[0041] Heat the special asphalt mixing tank...

Embodiment 2

[0043] Weigh 94kg of sulfur, 2kg of EVA (43% vinyl acetate, softening point of 83°C), 2kg of waste rubber powder, 1kg of hard asphalt (penetration of 28 1 / 10mm petroleum asphalt), 1kg of fly ash, Put the hard asphalt-waste rubber powder-fly ash-sulfur-EVA into the hopper of the kneader in the order, stir evenly and knead the material into a dough shape, and start the vacuum system at the same time to collect the generated gas for environmental protection treatment. Then start the lower discharge screw and the cutting and granulating system to carry out extrusion and granulation to form granules with a diameter of 3 mm and a length of 2 mm to 3 mm to obtain the anti-rutting modifier. The stirring speed of the kneader is 1500 rpm, the stirring time is 45 minutes, the kneading temperature is 110°C, and the extrusion temperature is 100°C. The ratio of raw materials and properties of modifiers are shown in Table 1.

[0044] Pre-heat the special asphalt mixing tank to a constant te...

Embodiment 3

[0046] Weigh 82kg of sulfur, 6kg of EVA (with a vinyl acetate content of 55%, and a softening point of 96°C), 6kg of waste rubber powder, 3kg of hard asphalt (with a penetration of 18 1 / 10mm coal tar pitch), and 3kg of fly ash. Hard asphalt-waste rubber powder-fly ash-sulfur-EVA are put into the hopper of the kneader in sequence, stirred evenly and the materials are kneaded into a dough shape, and the vacuum system is started at the same time to collect the generated gas for environmental protection treatment. Then start the lower discharge screw and the cutting and granulating system to carry out extrusion and granulation to form granules with a diameter of 3 mm and a length of 2 mm to 3 mm to obtain the anti-rutting modifier. The stirring speed of the kneader is 1400 rpm, the stirring time is 60 minutes, the kneading temperature is 95°C, and the extrusion temperature is 110°C. The ratio of raw materials and properties of modifiers are shown in Table 1.

[0047] Heat the spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com