Clean production technique of 1,4-dihydroxy anthraquinone

A dihydroxyanthraquinone, clean production technology, applied in quinone preparation, quinone separation/purification, preparation of organic compounds, etc., can solve the problems of low reaction activity, low reaction yield, increased yield of side reactions, etc. The effect of production cost, elimination of pollution and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

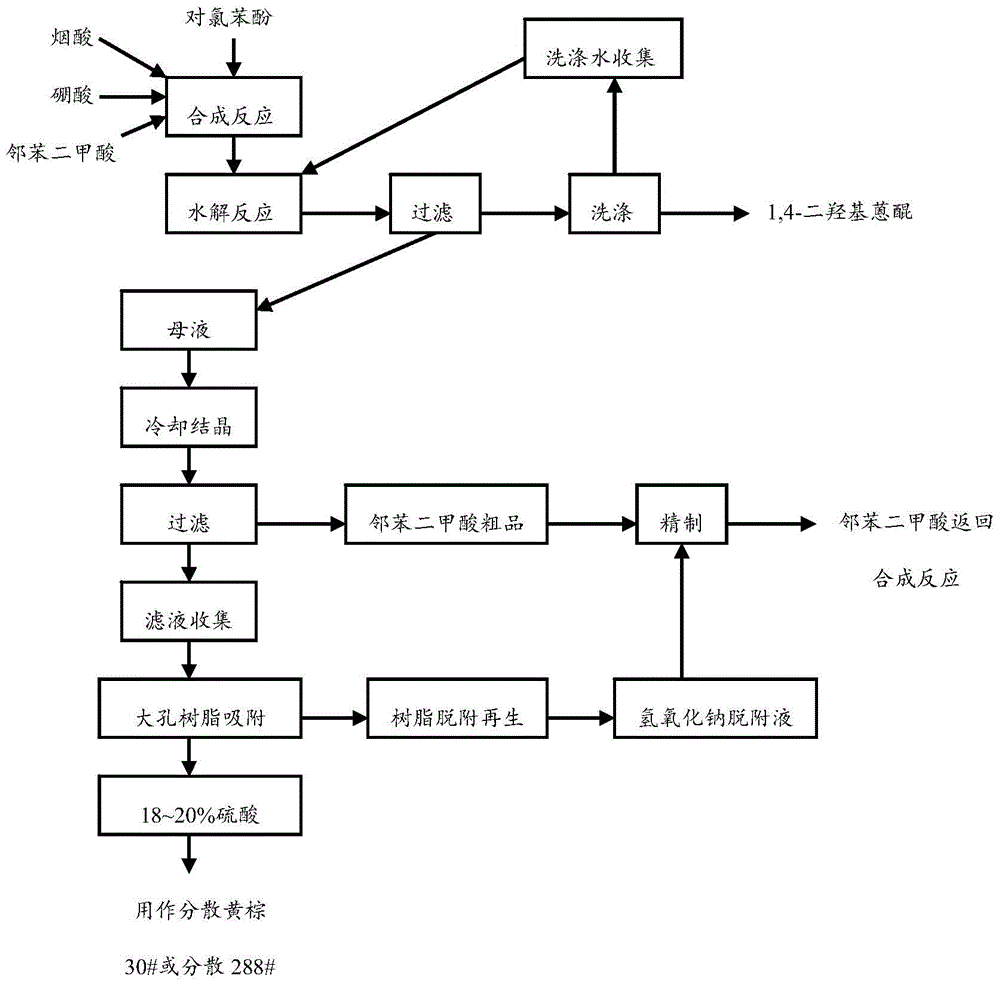

Image

Examples

Embodiment 1

[0040] Add 215g of 20% oleum, 26g of boric acid and 67.8g of phthalic acid in the 500ml four-neck flask equipped with a condensation recovery device, heat up to 160°C and dehydrate for 2 hours (this process is mainly for boric acid to dehydrate to generate pyroboric acid and Metaboric acid, no phthalic anhydride was found in the sampling analysis), then 37.5g of p-chlorophenol was added dropwise, after the drop was completed, the temperature was raised to 195°C-200°C and the temperature was maintained for 6 hours. Cool down and wait for dilution.

[0041] Add 860g of hot water into a 2000ml beaker, put in the material to be diluted, and then keep it at 100°C-105°C for 4 hours for hydrolysis. Filter, collect mother liquor 1100g, CODcr content is 30000mg / L, sulfuric acid mass percentage concentration is 20.5%. The filter cake is washed with hot water, and the washing water is collected as the bottom water for the next batch of dilution. The filter cake is dried to obtain 1,4-d...

Embodiment 2

[0045] Add niacin 215g and boric acid 26g in a 500ml four-neck flask equipped with a condensation recovery device, and recycle 15g of phthalic acid in Example 1, add 57g of phthalic acid newly, heat up to 150°C for dehydration for 2 hours, add dropwise Chlorophenol 37.5g, after dripping, the temperature was raised to 195°C-200°C and the temperature was kept for 6 hours. Cool down and wait for dilution.

[0046] Add 1000 g of the washing water of Example 1 into a 2000 ml beaker, put in the material to be diluted, and then heat-preserve and hydrolyze at 100° C. to 105° C. for 4 hours. Filter, collect mother liquor 1220g, CODcr content is 36000mg / L, and sulfuric acid acidity is 19.8%. The filter cake is washed with hot water, and the washing water is collected as the bottom water for the next batch of dilution. The filter cake is dried to obtain 1,4-dihydroxyanthraquinone with a content of 97.8% and a yield of 90.6%.

[0047] Put the mother liquor into a 2000ml beaker, cool do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com