Method for continuously producing dimethyl carbonate and co-producing 1, 2-propylene glycol by virtue of transesterification method

A technology of dimethyl carbonate and propylene glycol is applied in the preparation of carbonate/haloformate, the preparation of organic carbonates, the production of bulk chemicals, etc. Separation and other problems, to achieve the effect of high yield, reduced labor intensity, and less emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

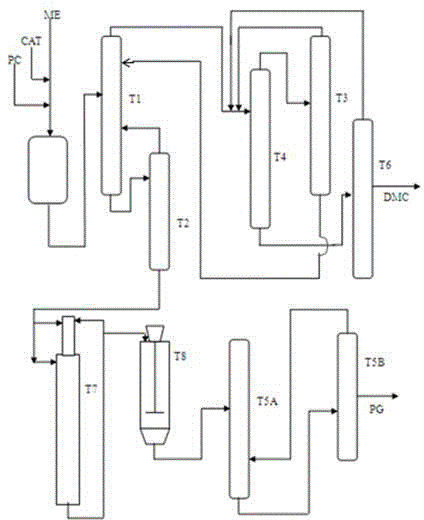

[0028] Embodiment 1 A method for continuously producing dimethyl carbonate and co-producing 1,2-propanediol by transesterification method, comprising the following steps:

[0029] (1) Reactive distillation: propylene carbonate, methanol and methanol alkali metal catalyst are sent into the mixing tank for mixing, the molar ratio of methanol and propylene carbonate in the mixture is 7:1, and the content of methanol metal catalyst is the total weight of the mixture The reaction temperature of propylene carbonate and methanol in the synthesis tower is 70-75 ℃, the pressure is normal pressure, the reflux ratio is 1.0, and the reaction residence time is 2h;

[0030] (2) recovery of dimethyl carbonate: the methanol and dimethyl carbonate azeotrope at the top of reactive distillation column T1 are sent into pressurized distillation column T4, and pressure distillation is carried out, and the temperature in the tower is 130-140 ° C, The pressure is 0.5-0.6MPa, and the obtained tower st...

Embodiment 2

[0037] Embodiment 2 A method for continuously producing dimethyl carbonate and co-producing 1,2-propanediol by transesterification method, comprising the following steps:

[0038] (1) Reactive distillation: propylene carbonate, methanol and methanol alkali metal catalyst are sent into the mixing tank for mixing, the molar ratio of methanol and propylene carbonate in the mixture is 11:1, and the content of methanol metal catalyst is the total weight of the mixture. The reaction temperature of propylene carbonate and methanol in the synthesis tower is 70-75 ℃, the pressure is normal pressure, the reflux ratio is 3.0, and the reaction residence time is 1h;

[0039] (2) Reclaiming dimethyl carbonate: the methanol and dimethyl carbonate azeotrope at the top of reactive distillation column T1 are sent into pressurized distillation column T4, and pressure distillation is carried out, and the temperature in the tower is 150-170° C., The pressure is 0.6-0.7MPa, and the obtained tower s...

Embodiment 3

[0046] Embodiment 3 A method for continuously producing dimethyl carbonate and co-producing 1,2-propanediol by transesterification method, comprising the following steps:

[0047] (1) Reactive distillation: propylene carbonate, methanol and methanol alkali metal catalyst are sent into the mixing tank for mixing, the molar ratio of methanol and propylene carbonate in the mixture is 9:1, and the content of methanol metal catalyst is the total weight of the mixture. The reaction temperature of propylene carbonate and methanol in the synthesis tower is 70-75 ℃, the pressure is normal pressure, the reflux ratio is 2.0, and the reaction residence time is 1h;

[0048] (2) Reclaiming dimethyl carbonate: the methanol and dimethyl carbonate azeotrope at the top of reactive distillation tower T1 are sent into pressurized distillation tower T4, and pressurized distillation is carried out, and the temperature in the tower is 140-150 ℃, The pressure is 0.6MPa, and the obtained tower still l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com